Self-powered micro-fluidic chip and manufacturing method thereof

A microfluidic chip, self-powered technology, applied in chemical instruments and methods, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., to achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

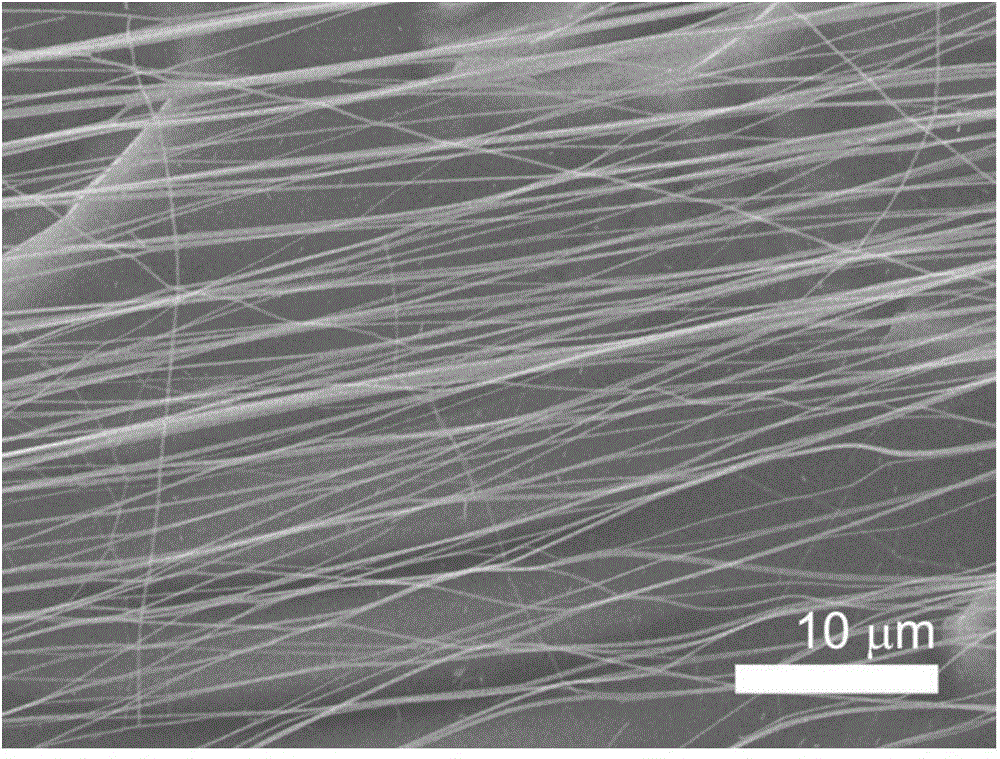

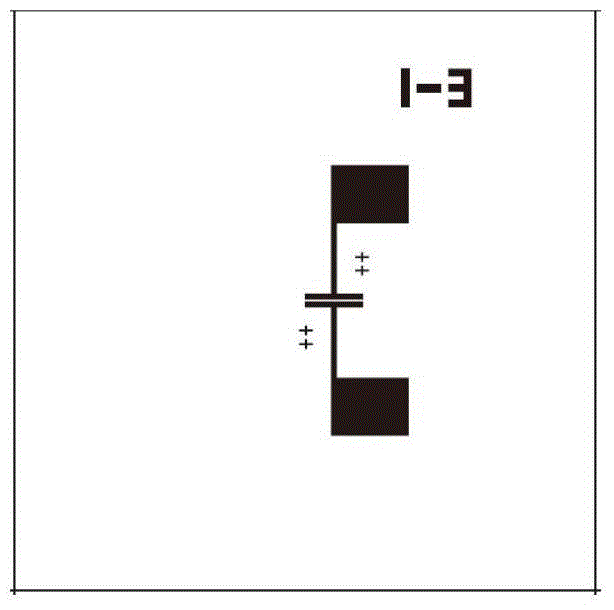

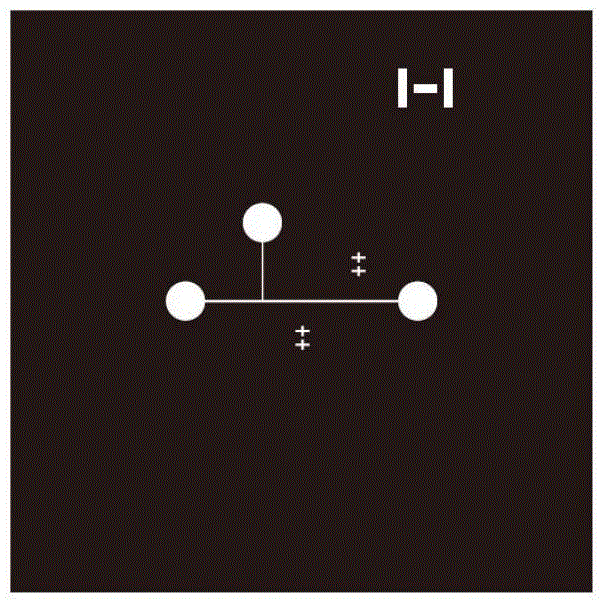

[0046] figure 2 It is a schematic diagram of the mask plate used for the electrode. The length of the electrode is 3 mm, the distance between the electrodes is 100 μm, and the overall size of the mask plate is 30 mm in length and width. image 3 It is a schematic diagram of the mask plate used for microfluidic channels. In the figure, the width of the main flow channel is b=100μm, the width of the branch channel is a=50μm, and the overall size of the mask plate is 30mm in length and width; the main flow channel and the branch flow channel of the liquid The angle between them is 90 degrees.

[0047] 1. Detection electrode preparation

[0048] (1) Substrate cleaning: Put the quartz glass sheet with a length and width of 20 mm and a thickness of 2 mm into acetone, alcohol, and deionized water in sequence, and ultrasonically clean it for 10 minutes at room temperature. After ultrasonic cleaning, pour out the last deionized water. Add new deionized water.

[0049] (2) Photolith...

Embodiment 2

[0076] refer to figure 2 , image 3 , in the mask plate used as the electrode, the length of the electrode is 3mm, the distance between the electrodes is 100 μm, and the overall size of the mask plate is 30mm in length and width. For the mask plate used for the microfluidic channel, the width of the main flow channel is b=200 μm, the width of the branch channel is a=50 μm, and the overall size of the mask plate is 30 mm in length and width; the angle between the main flow channel and the branch flow channel of the liquid is 90 degrees.

[0077] 1. Detection electrode preparation

[0078] (1) Substrate cleaning: Put the quartz glass sheet with a length and width of 20 mm and a thickness of 2 mm into acetone, alcohol, and deionized water in sequence, and ultrasonically clean it for 10 minutes at room temperature. After ultrasonic cleaning, pour out the last deionized water. Add new deionized water.

[0079] (2) Photolithography process: Take the cleaned quartz glass sheet a...

Embodiment 3

[0106] refer to figure 2 , image 3 , in the mask plate used as the electrode, the length of the electrode is 3 mm, the distance between the electrodes is 200 μm, and the overall size of the mask plate is 30 mm in length and width. The mask plate used for the microfluidic channel, the width of the main flow channel is b=300μm, the width of the branch channel is a=50μm, the overall size of the mask plate is 30mm in length and width; the angle between the main flow channel and the inlet branch channel is 90 degrees.

[0107] 1. Detection electrode preparation

[0108] (1) Substrate cleaning: Put the quartz glass sheet with a length and width of 20 mm and a thickness of 2 mm into acetone, alcohol, and deionized water in sequence, and ultrasonically clean it for 10 minutes at room temperature. After ultrasonic cleaning, pour out the last deionized water. Add new deionized water.

[0109] (2) Photolithography process: Take the cleaned quartz glass sheet and dry it with nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com