Hydrophilic/hydrophobic transition polyelectrolyte/titanium dioxide composite nanofiltration membrane and preparation method thereof

A technology of composite nanofiltration membrane and polyelectrolyte, which is applied in the field of composite nanofiltration membrane, hydrophilic/hydrophobic conversion composite nanofiltration membrane and its preparation, to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

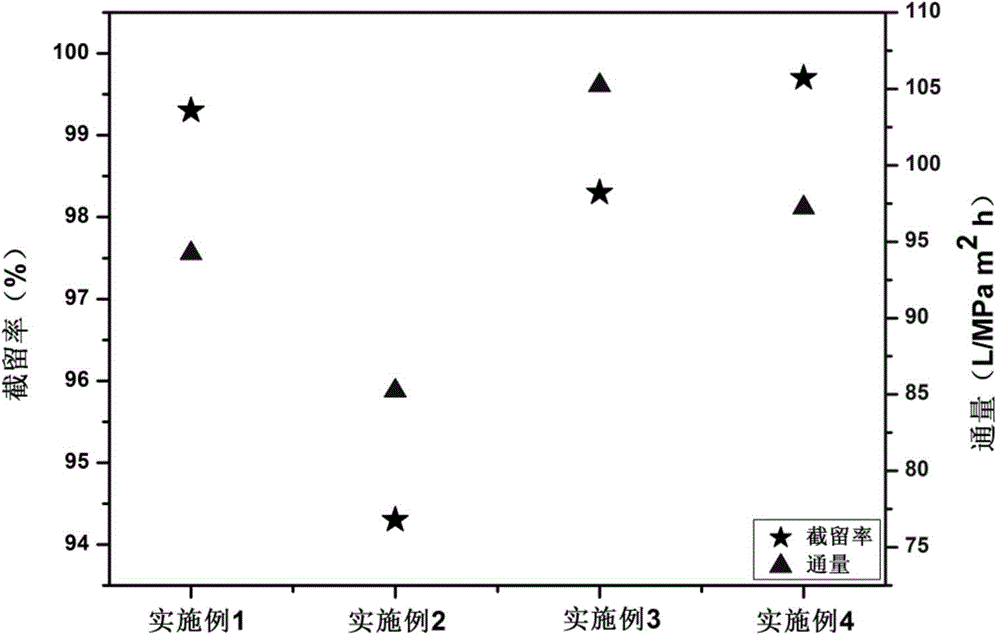

Examples

Embodiment 1

[0025] (1) Preparation of pre-assembled layers

[0026] First, immerse the pretreated ultrafiltration base membrane with a negative charge on the surface in a cationic polyelectrolyte solution with a concentration of 5.0 g / L, assemble the cationic polyelectrolyte, take it out for 20 minutes, and wash it fully with deionized water; then soak the membrane Assemble the anionic polyelectrolyte in an anionic polyelectrolyte solution with a concentration of 5.0 g / L, take it out for 20 minutes, and wash it fully with deionized water, so that the obtained pair of cationic polyelectrolyte and anionic polyelectrolyte are used as a pre-assembled layer;

[0027] (2) Hydrophilic polyelectrolyte / TiO 2Preparation of Composite Nanofiltration Membrane

[0028] The pre-assembled layer prepared in step (1) was soaked in a concentration of 0.15g / L positively charged titanium dioxide (TiO 2 ) The concentration of nanoparticles is 5.0g / L in the cationic polyelectrolyte, take it out after 20min, f...

Embodiment 2

[0033] (1) Preparation of pre-assembled layers

[0034] First, immerse the pretreated ultrafiltration base membrane with a negative charge on the surface in a cationic polyelectrolyte solution with a concentration of 5.0 g / L, assemble the cationic polyelectrolyte, take it out for 30 minutes, and wash it fully with deionized water; then soak the membrane Assemble the anionic polyelectrolyte in an anionic polyelectrolyte solution with a concentration of 5.0 g / L, take it out for 30 minutes, and wash it fully with deionized water, so that the obtained pair of cationic polyelectrolyte and anionic polyelectrolyte are used as a pre-assembled layer;

[0035] (2) Polyelectrolyte / TiO 2 Preparation of Composite Nanofiltration Membrane

[0036] The pre-assembled layer prepared in step (1) was soaked in a concentration of 0.10g / L positively charged titanium dioxide (TiO 2 ) The concentration of nanoparticles is 5.0g / L in the cationic polyelectrolyte, take it out after 30min, fully wash w...

Embodiment 3

[0043] (1) Preparation of pre-assembled layers

[0044] First, immerse the ultrafiltration base membrane with a negative charge on the surface after pretreatment in a cationic polyelectrolyte solution with a concentration of 5.0 g / L, assemble the cationic polyelectrolyte, take it out for 15 minutes, and wash it fully with deionized water; then soak the membrane Assemble the anionic polyelectrolyte in an anionic polyelectrolyte solution with a concentration of 5.0 g / L, take it out for 15 minutes, and wash it fully with deionized water, so that the obtained pair of cationic polyelectrolyte and anionic polyelectrolyte are used as a pre-assembled layer;

[0045] (2) Hydrophilic polyelectrolyte / TiO 2 Preparation of Composite Nanofiltration Membrane

[0046] The pre-assembled layer prepared in step (1) is soaked in a concentration of 0.05g / L positively charged titanium dioxide (TiO 2 ) The concentration of nanoparticles is 5.0g / L in the cationic polyelectrolyte, take it out after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com