Wire mesh gas-liquid separator capable of preventing liquid drop re-entrainment and application of wire mesh gas-liquid separator

A technology of gas-liquid separator and carrying liquid, which is applied in the direction of separation method, dispersed particle separation, chemical instruments and methods, etc., which can solve the problems of energy and chemical safety and environmental protection hazards, and the deterioration of separation effect, so as to achieve efficient and safe production and control carrying , the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

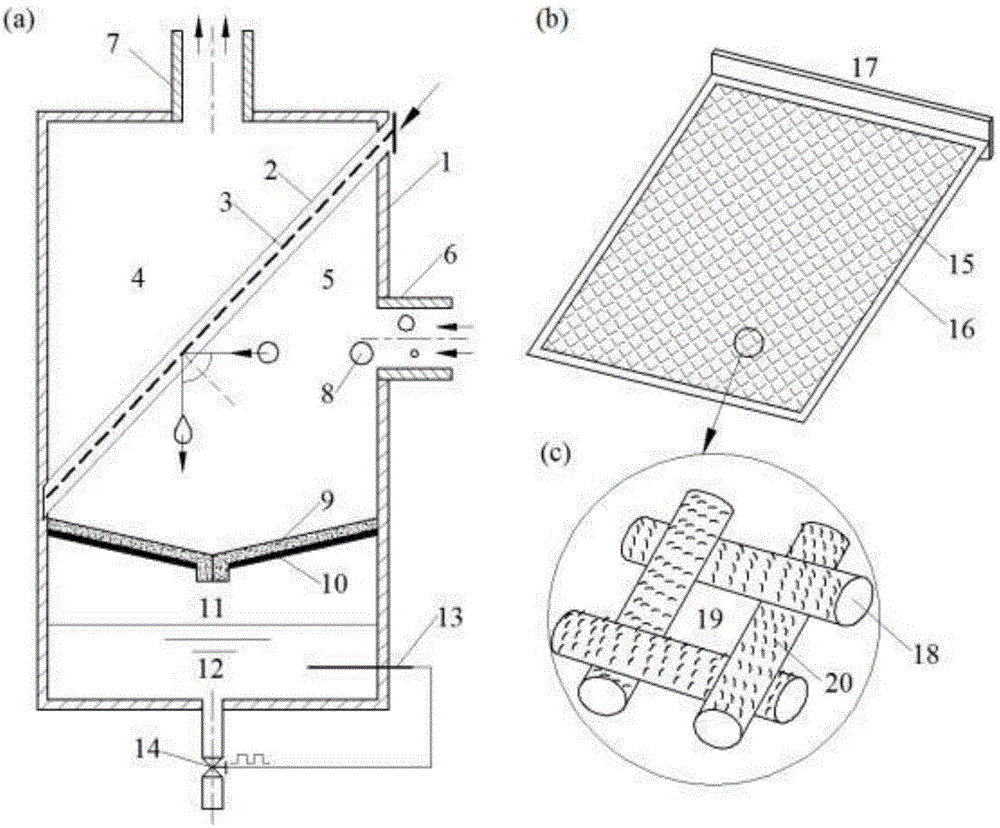

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings, but the claims of the present invention are not limited in any way.

[0021] For steam-water separation process. Separator shell 1 is made of 304 stainless steel, with dimensions of length 500mm, width 500mm, height 800mm, and shell thickness 20mm. The liquid storage chamber 11 separated by the baffle plate 10 is 300 mm high, and the rest of the space is divided into two parts, the gas chamber 4 and the gas-liquid chamber 5, by the drawer-type super liquid-phobic screen plate 3 at an angle of 45°. The baffle 10 is made of 2mm thick stainless steel, the lyophilic metal foam 9 is made of 15mm thick 80-mesh copper foam, and the baffle 10 and the lyophilic metal foam 9 are soldered. The baffle forms a funnel with an inclination angle of 30°, and the side length of the central hole of the funnel is 100mm. The steam-water mixture inlet 6 has a pipe diameter of 150mm, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com