Instant black tea extract

A black tea extract, black tea technology, applied in the direction of tea extraction, etc., can solve the problems of insufficient clarity of soup color, poor drinking, affecting taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

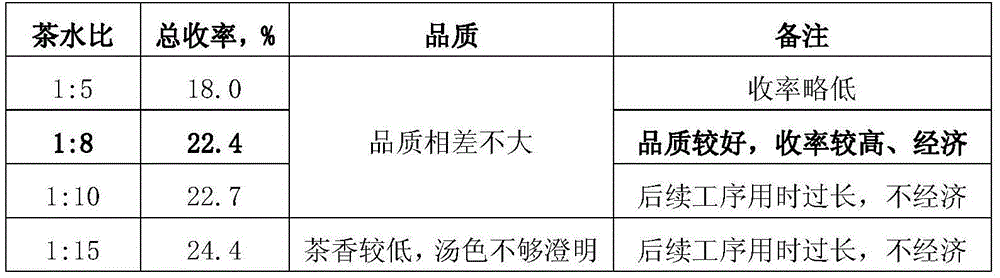

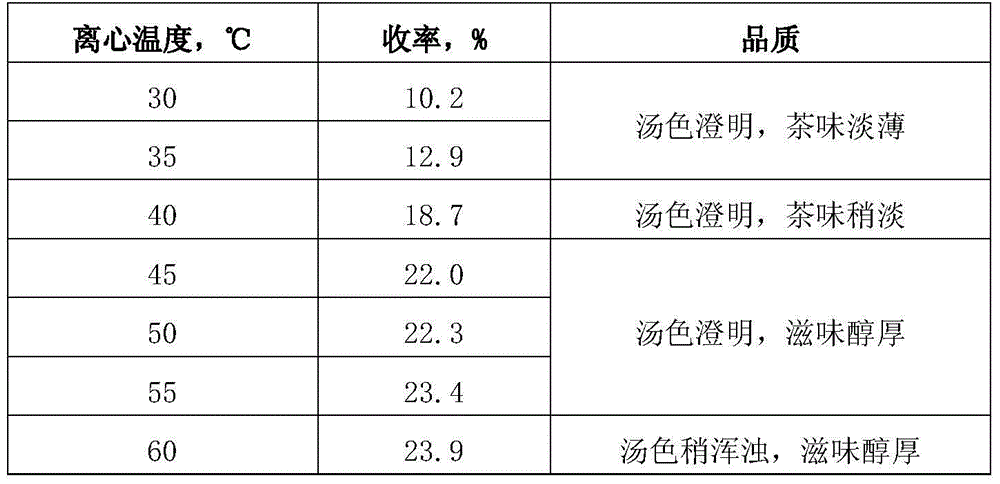

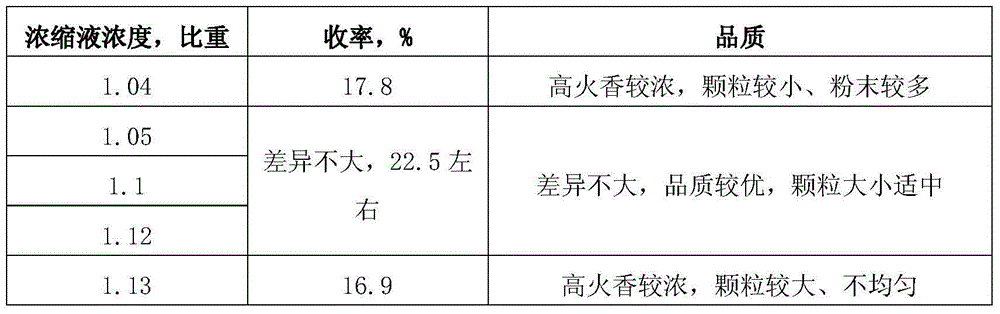

Method used

Image

Examples

Embodiment 1

[0045] (A) Take 100kg of black tea, add 5 times of water, extract at a constant temperature of 35°C, extract twice, 0.5h each time, filter to obtain the extract I, (B) add 5 times of water, keep boiling for 0.5h, filter, To obtain the extract II,

[0046](C) Combine the extracts I and II, concentrate at 70°C until the specific gravity is 1.030-1.035, and centrifuge at 45-55°C for later use. The centrifugate was concentrated again at a temperature of 70°C to a specific gravity of 1.05-1.12. The obtained concentrated solution is directly sprayed dry, the air inlet temperature is set to 160°C, the holding temperature is 45-60°C, and the feed rate of the peristaltic pump is 200-300L / h.

Embodiment 2

[0048] (A) Take 100kg of black tea, add 15 times the amount of water, extract at a constant temperature of 60°C, extract 3 times, each time for 1.5 hours, filter to obtain the extract I, (B) add 15 times the amount of water, keep boiling for 1.5 hours, filter, To obtain the extract II,

[0049] (C) Combine the extracts I and II, concentrate at 70°C until the specific gravity is 1.030-1.035, and centrifuge at 45-55°C for later use. The centrifugate was concentrated again at a temperature of 70°C to a specific gravity of 1.05-1.12. The obtained concentrated solution is directly sprayed dry, the air inlet temperature is set at 180°C, the holding temperature is 45-60°C, and the feed rate of the peristaltic pump is 200-300L / h.

Embodiment 3

[0051] (A) Take 100kg of black tea, add 8 times of water, extract at a constant temperature of 50°C, extract twice, each time for 1 hour, and filter to obtain extract I, (B) add 8 times of water, keep boiling for 1 hour, filter, To obtain the extract II,

[0052] (C) Combine the extracts I and II, concentrate at 70°C until the specific gravity is 1.030-1.035, and centrifuge at 45-55°C for later use. The centrifugate was concentrated again at a temperature of 70°C to a specific gravity of 1.05-1.12. The obtained concentrated solution is directly sprayed dry, the air inlet temperature is set to 170°C, the holding temperature is 45-60°C, and the feed rate of the peristaltic pump is 200-300L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com