Environment-friendly beta-cypermethrin emulsion in water and preparing method thereof

A high-efficiency cypermethrin and environment-friendly technology, applied in botany equipment and methods, insecticides, biocides, etc., can solve problems such as poor biodegradability, high toxicity of alkylphenols, ecological environment, human and animal health and safety hazards, etc. Achieve the effects of low residue, improved environmental protection, and safe production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

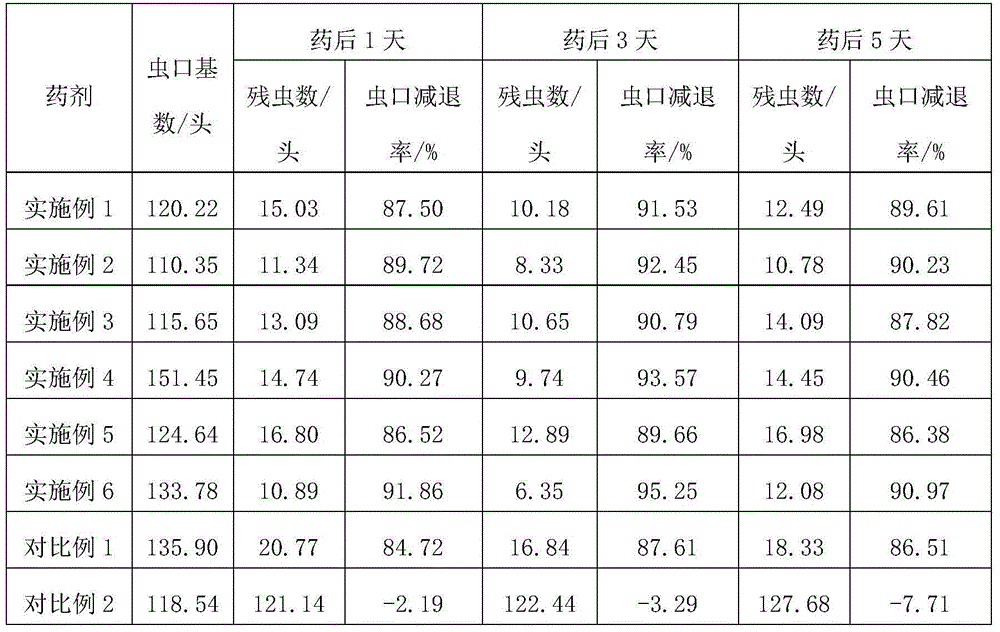

Examples

Embodiment 1

[0033] ⑴Add 25g of beta-cypermethrin into the beaker, add 120g of castor oil to it, fully stir to dissolve the original drug completely, then add 15g of fatty alcohol polyoxyethylene ether (AEO 3 ) and 5g alkyl glucoside (APG1214), continue stirring to form a homogeneous oil phase.

[0034] (2) Add 30g of n-butanol, 2g of polyvinylpyrrolidone and 0.5g of oxalic acid into 787.5g of deionized water in sequence, stir well to dissolve, and then add 15g of fatty alcohol polyoxyethylene ether carboxylate (AEC 9 Na), continue stirring to form a homogeneous aqueous phase.

[0035] (3) Turn on the high-shear emulsifier, and slowly add the water phase to the oil phase at a shear rate of 10000r / min. After the water phase is added, continue to shear for 5 minutes to obtain 1000g of 2.5% beta-cypermethrin water emulsion.

Embodiment 2

[0037] (1) Add 25g of beta-cypermethrin into a beaker, add 100g of palm oil to it, stir well to completely dissolve the original drug, then add 20g of castor oil polyoxyethylene ether (EL-10) and 5g of alcohol ether glycoside (AEG) to it, Stirring was continued to form a homogeneous oily phase.

[0038] (2) Add 20g of n-propanol, 3g of sodium carboxymethyl cellulose and 1g of citric acid into 816g of deionized water in turn, stir well to dissolve them, then add 10g of fatty alcohol polyoxyethylene ether phosphate (MAPK) to it, continue Stir to form a homogeneous aqueous phase.

[0039] (3) Turn on the high-shear emulsifier, and slowly add the water phase to the oil phase at a shear rate of 13000r / min. After the water phase is added, continue to shear for 5min to obtain 1000g of 2.5% beta-cypermethrin water emulsion.

Embodiment 3

[0041] (1) Add 50g of beta-cypermethrin into a beaker, add 50g of methyl palmitoleate and 75g of methyl laurate to it, stir fully to dissolve the original drug completely, then add 25g of methyl ricinoleate polyoxyethylene (CAMEE- 10), continue stirring to form a homogeneous oil phase.

[0042] (2) Add 50g of isopropanol, 3g of polyethylene glycol (PEG-400) and 3g of glacial acetic acid into 729g of deionized water in turn, stir well to dissolve, and then add 15g of potassium salt of fatty alcohol polyoxyethylene ether phosphate (MAPK) and 10g fatty acid methyl ester sulfonate (MES), continue stirring to form a homogeneous aqueous phase.

[0043] (3) Turn on the high-shear emulsifier, and slowly add the water phase to the oil phase at a shear rate of 20,000r / min. After the water phase is added, continue to shear for 10 minutes to prepare 1000g of 5% beta-cypermethrin water emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com