Nutrition pot continuous manufacturing machine

A nutrition bowl and making machine technology, applied in application, cultivation, agriculture, etc., can solve the problems of separation, complicated operation procedures, need to stack and other problems, and achieve the effect of no exhaust gas emission and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

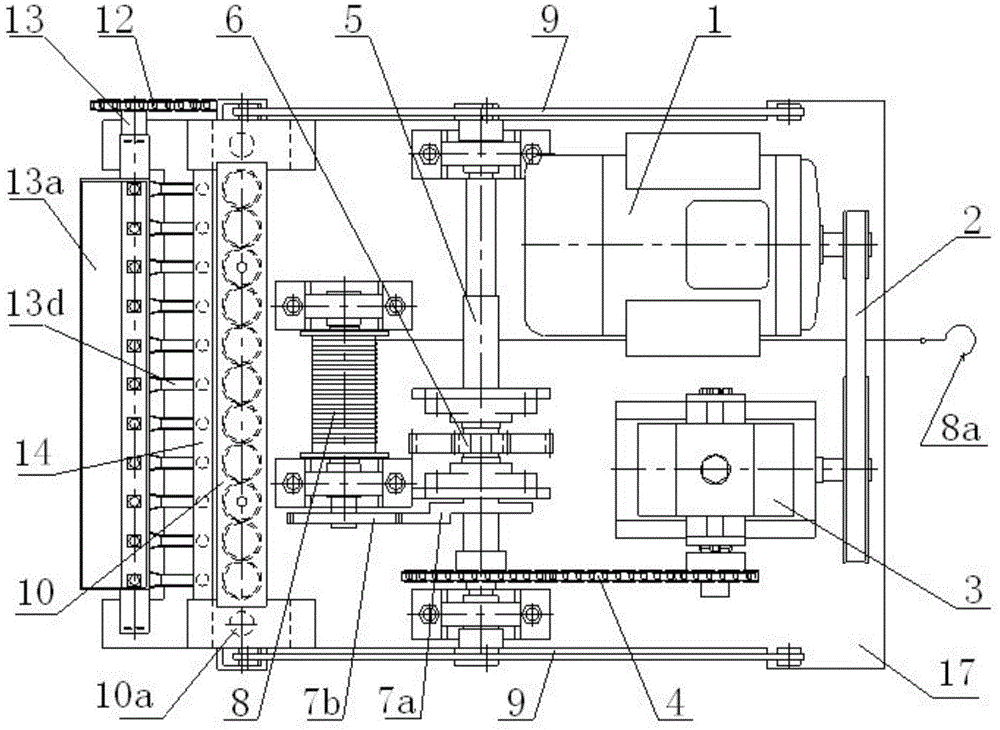

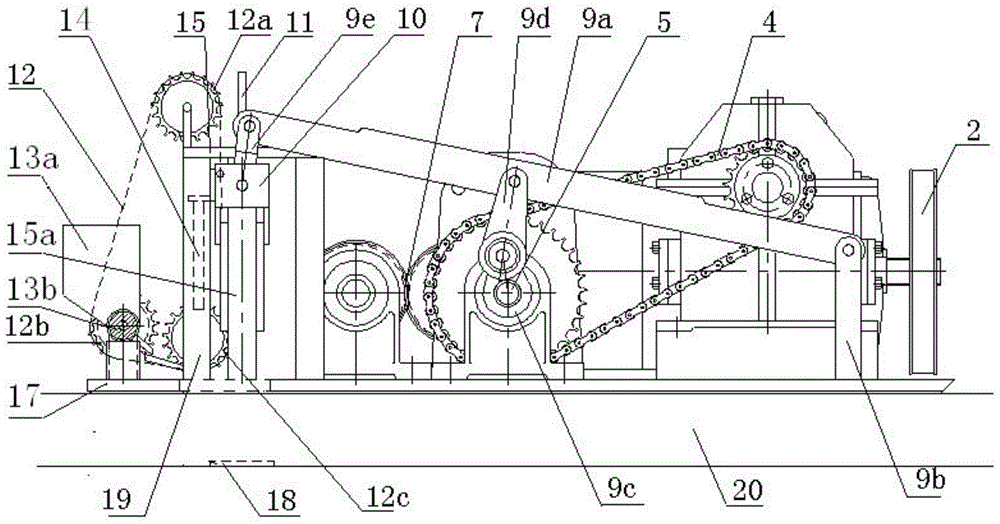

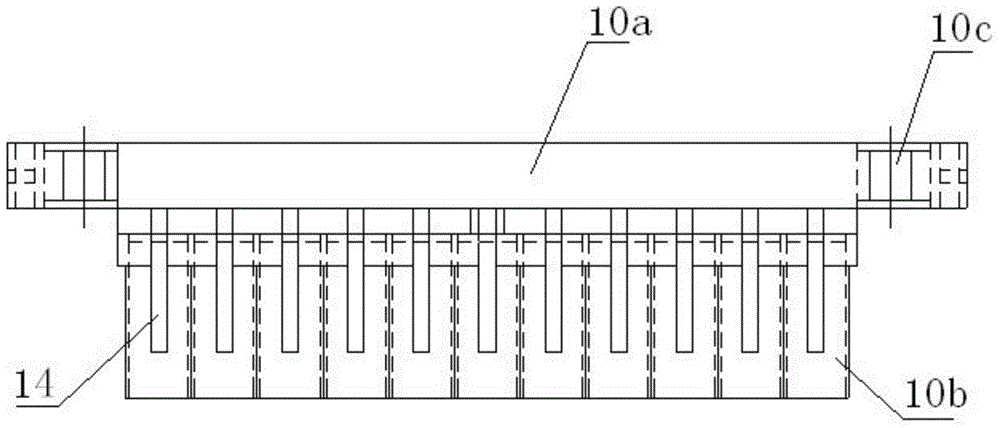

[0025] The nutritional bowl continuous making machine of the present invention mainly has two action processes: the first action process is intermittent walking of the nutritional bowl making machine; the second action process is bowl making and seed distribution. Two action processes circulate repeatedly, constitute the whole action process of the present invention.

[0026] Drive part: The direct drive part of the two action processes is the main drive shaft 5, such as figure 1 As shown, it is driven by the motor 1, the belt transmission mechanism 2, the reducer 3 and the chain transmission mechanism 4. The whole set of design above is mainly to reduce the speed of the motor 1 to the main drive shaft 5 and increase the torque to The design requirements of the nutritional bowl making machine are met.

[0027] Intermittent walking part: this part is powered by the main transmission shaft 5, further decelerates through the gear transmission mechanism 6, and then realizes the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com