Vibration type crushing and ridging box

A vibratory and powder ridge technology, which is applied in the fields of application, land preparation machinery, agricultural machinery and machinery, etc., can solve the problems of reducing the efficiency of cultivated land and working difficulties, and achieve the effect of improving the efficiency of cultivated land, strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

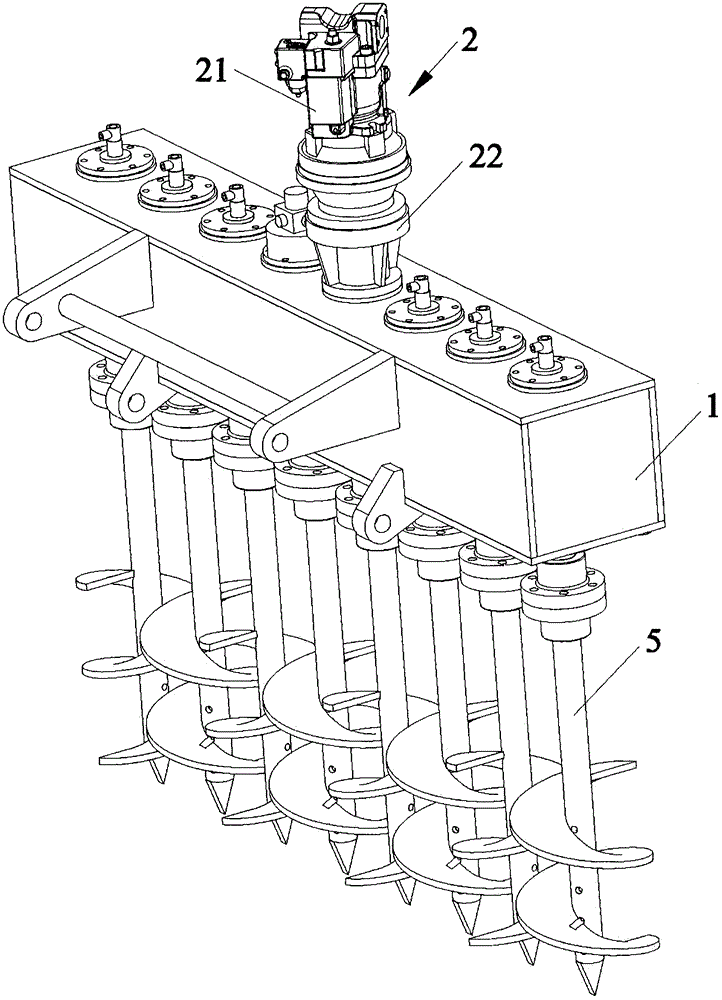

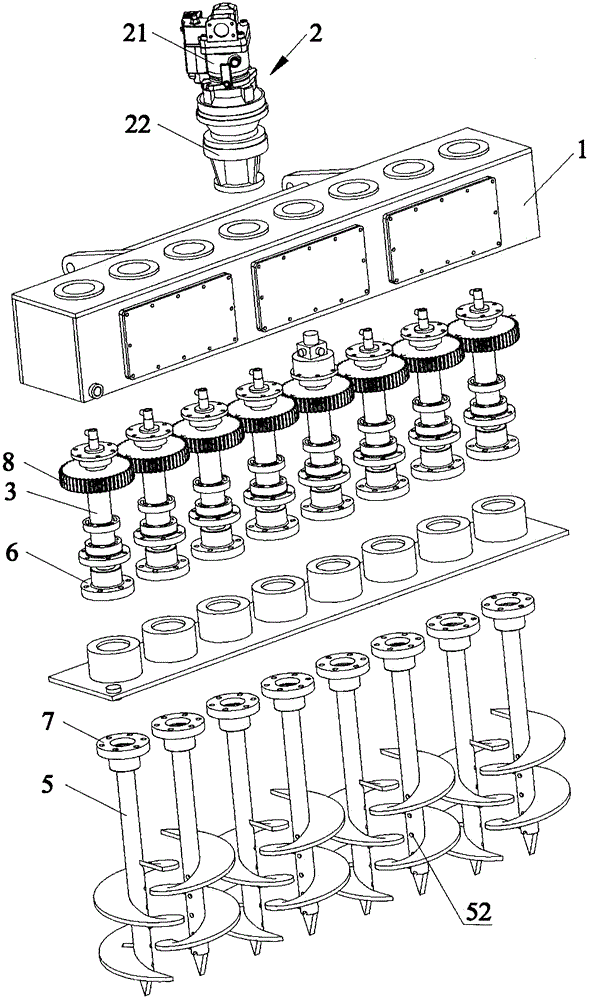

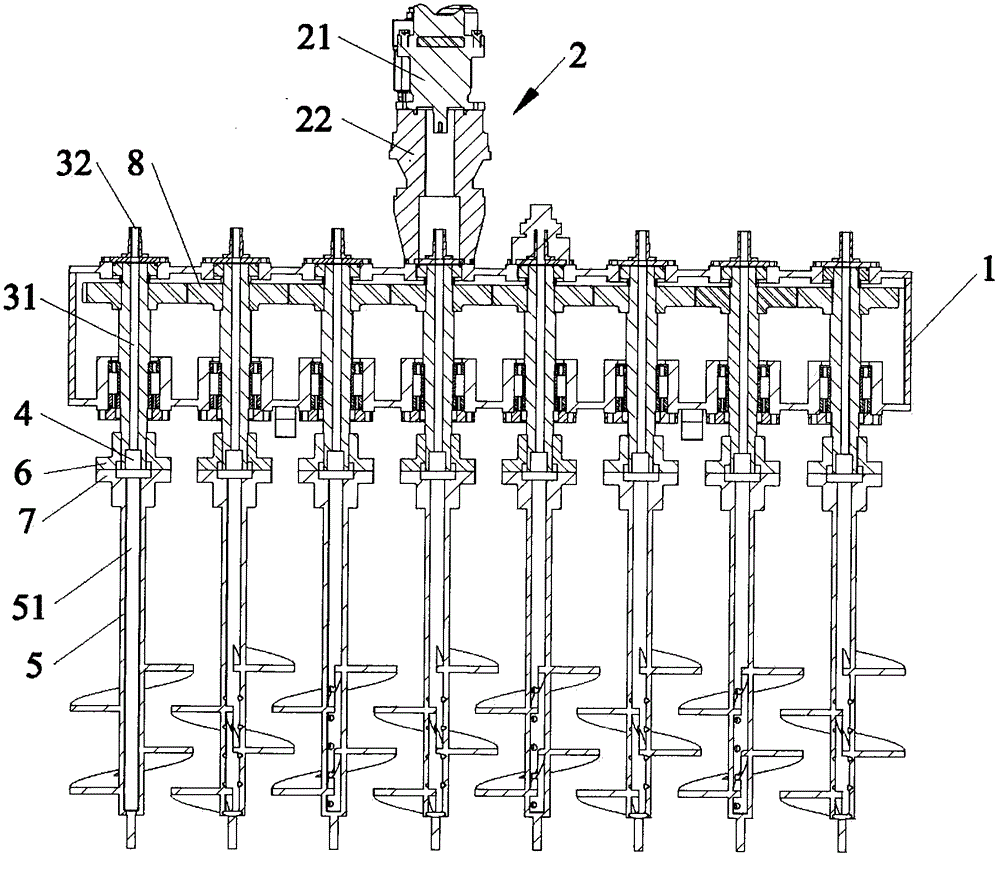

[0020] Such as Figure 1 to Figure 3 As shown, the direction of this embodiment is figure 1 The placement direction of the vibratory powder ridge box shown in the present embodiment is a vibratory powder ridge box, which includes a box body 1, a driving mechanism 2 and a drill pipe 5, and the driving mechanism 2 is arranged above the box body 1. , the drill rod 5 is arranged below the box body 1, and the drive mechanism 2 drives and connects the drill rod 5. It also includes a transmission shaft 3 and an eccentric shaft 4 that are pierced through the box body 1. One end of the transmission shaft 3 is connected to the drive mechanism 2. The other end of the transmission shaft 3 is connected with one end of the eccentric shaft 4 , and the other end of the eccentric shaft 4 is connected with the drill rod 5 . The present invention has a simple structure. When working, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com