Method for preparing super capacitor electrode material made of nickel oxide nanosheet grown on micro carbon tube

A technology of nickel oxide nanosheets and supercapacitors, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve problems such as unsatisfactory cycle stability, poor rate performance, and low conductivity, and achieve The effect of increasing the electrochemical reaction area, excellent rate performance, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

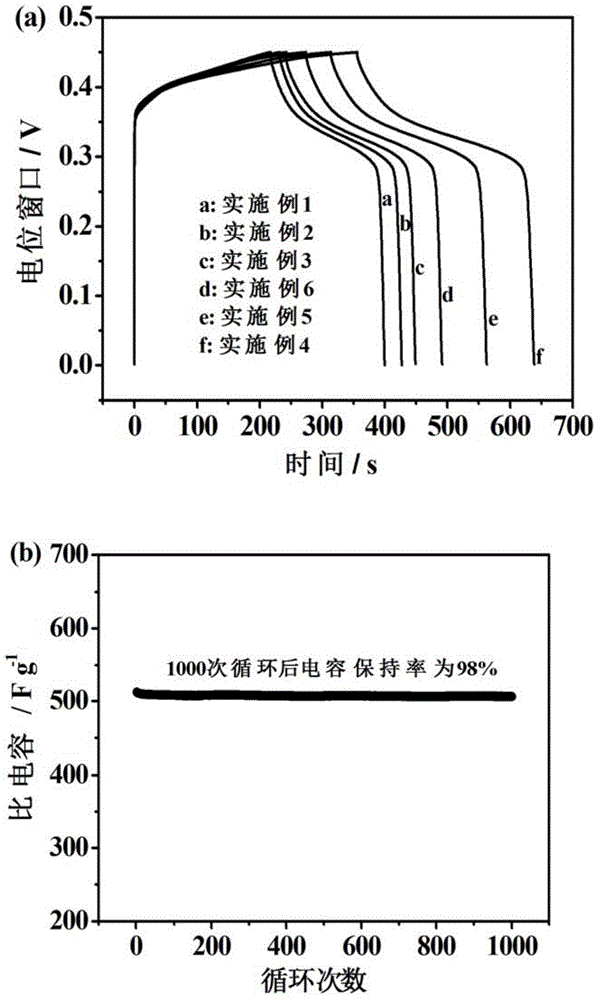

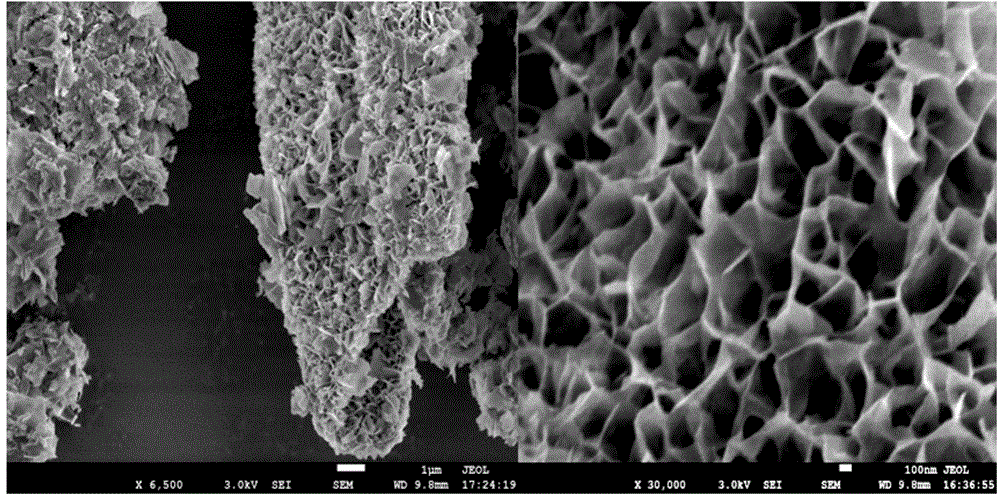

Embodiment 1

[0022] First, soak the collected catkins in absolute ethanol solution, and ultrasonically disperse them for 10 minutes to obtain a cleaned catkin sample, then put the cleaned catkin sample into a carbonization furnace, and carbonize it at 500°C under an argon atmosphere to obtain carbon microtubes , and then 0.1g of carbon microtubes were added to 50ml of N,N-dimethylformamide, and ultrasonically obtained solution A; then 1g of Ni(NO 3 ) 2 ·6H 2 O powder was dissolved in 10ml of deionized water to form solution B. Then, solution A was slowly added to solution B dropwise under magnetic stirring. The obtained mixed solution was transferred to a reaction kettle and heated at 100° C. for 36 h. After the reaction was completed, the obtained product was suction-filtered, washed and dried. Finally, under an argon atmosphere, calcined at 150°C for 4 hours to obtain a specific surface area of 189m 2 g -1 , NiO nanosheet / carbon microtube composite material with NiO loading rate o...

Embodiment 2

[0025] First, soak the collected catkins in absolute ethanol solution, and ultrasonically disperse them for 10 minutes to obtain a cleaned catkin sample, then put the cleaned catkin sample into a carbonization furnace, and carbonize it at 1000°C under a nitrogen atmosphere to obtain carbon microtubes. Then take 0.5g of carbon microtubes and add them to 100ml of N,N-dimethylformamide, and obtain solution A through ultrasonication; then add 1g of Ni(NO 3 ) 2 ·6H 2 O powder was dissolved in 100ml of deionized water to form solution B. Under vigorous stirring of the emulsifier, slowly add solution A to solution B drop by drop. The obtained mixed solution was transferred to a reaction kettle and heated at 180° C. for 18 hours. After the reaction was completed, the obtained product was suction-filtered, washed, and dried at 60° C. Finally, under a nitrogen atmosphere, calcined at 500°C for 4 hours to obtain a specific surface area of 180m 2 g -1 , NiO nanosheet / carbon microtu...

Embodiment 3

[0028] First, soak the collected catkins in absolute ethanol solution, and ultrasonically disperse them for 10 minutes to obtain a cleaned catkin sample, then put the cleaned catkin sample into a carbonization furnace, and carbonize it at 600°C under a nitrogen atmosphere to obtain carbon microtubes. Then get 0.3g of micro-carbon tubes and join them in 100ml of N,N-dimethylformamide, through ultrasonication, to obtain solution A; then add 1g of Ni(NO 3 ) 2 ·6H 2 O powder was dissolved in 80ml of deionized water to form solution B. Add solution A to solution B slowly drop by drop under the condition of strong stirring in a cell grinder. The obtained mixed solution was transferred to a reaction kettle, and heated at 250°C for 12 hours. After the reaction, the obtained product was suction-filtered, washed, and dried at 60°C. Finally, under a nitrogen atmosphere, calcined at 500°C for 4 hours to obtain a specific surface area of 186m 2 g -1 , the nickel oxide nanosheet / carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com