Method of uniformly optimizing illuminating LED array light source for strip steel surface detection

A technology of LED array and surface detection, applied in the direction of gene model, etc., can solve the problems such as the visual detection requirements that cannot meet the uniform illumination of the strip hot rolling production line, the complex lens production, and the limited illumination width, etc., to reduce the manual design time, The light source has a compact structure and can achieve the effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

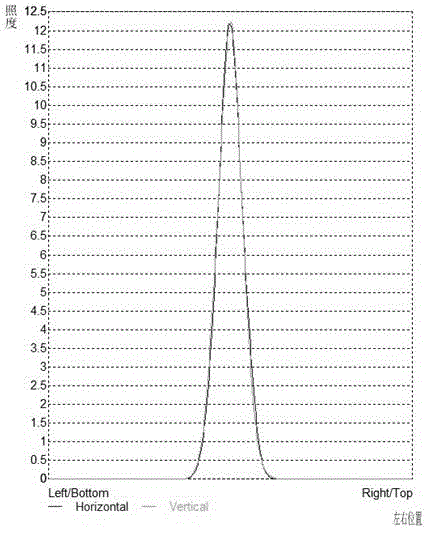

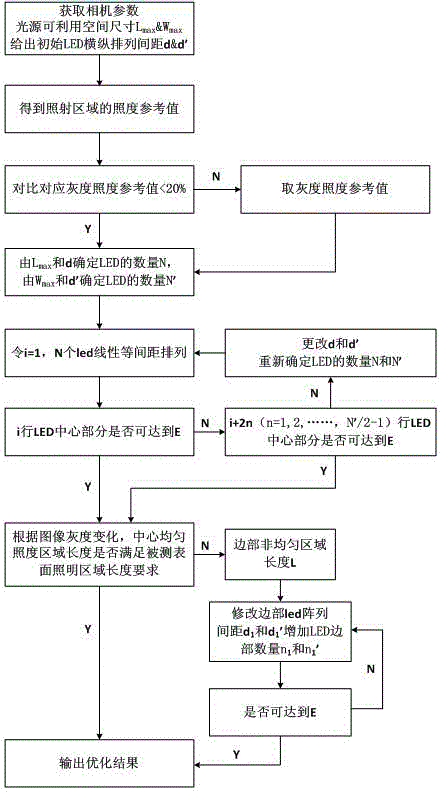

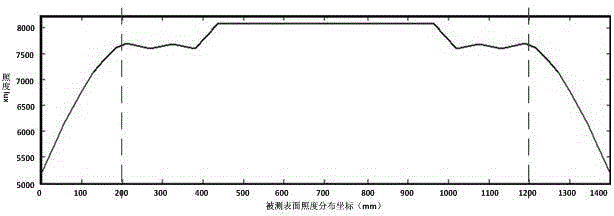

[0081] The light source designed according to the above method has been applied in the hot-rolled strip steel production line. Due to space constraints, the effective illumination width of the surface light source is only 1520mm, and it needs to achieve uniform illumination within the 1000mm detection area, and the illuminance is greater than 7000lux. According to the above method, the optimization calculation is carried out.

[0082] First, according to the on-site installation light source space, the maximum installation size of the light source is 1520mm, and the width is not limited. At the same time, the horizontal and vertical spacing calculated by the initial setting of the LED array is 56mm and 22mm.

[0083] Second, according to the maximum installation size length and width of the light source provided in step 1, and the sum of the horizontal and vertical spacing of the LED array, the number of horizontal and vertical LED arrangements is directly calculated to be 28 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com