Wind-electricity draught fan blade crack damage online monitoring device and monitoring method thereof

A technology of fan blades and monitoring devices, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve the problems of reducing monitoring efficiency and heavy workload, and achieve improved monitoring accuracy, more adaptability, fast and accurate online real-time The effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

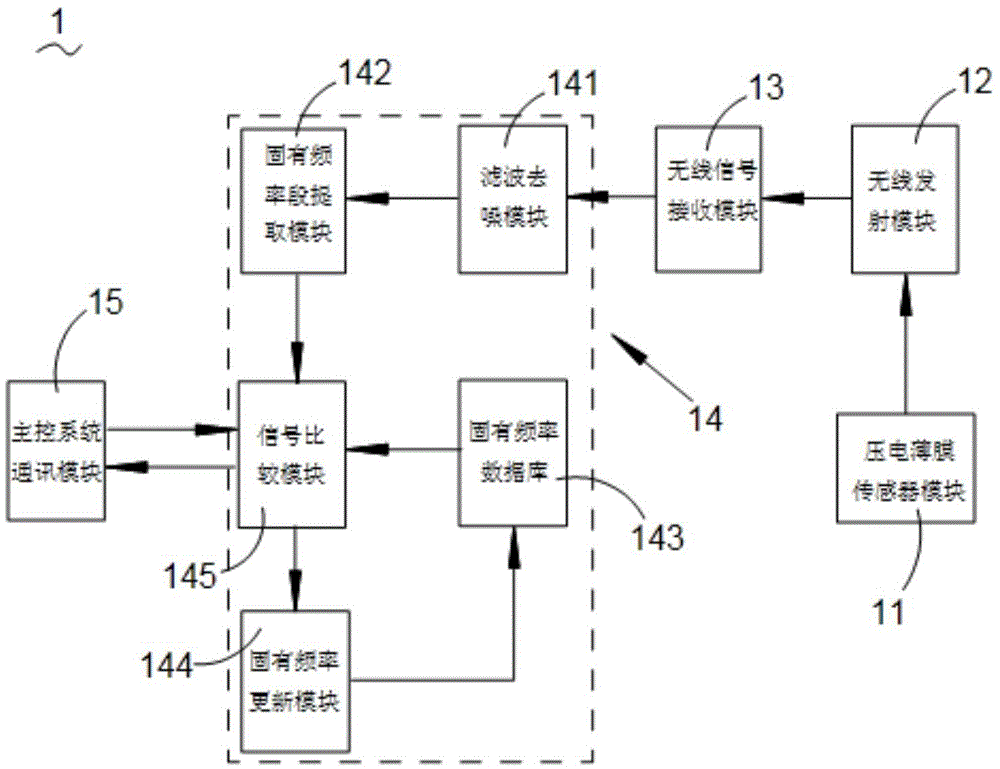

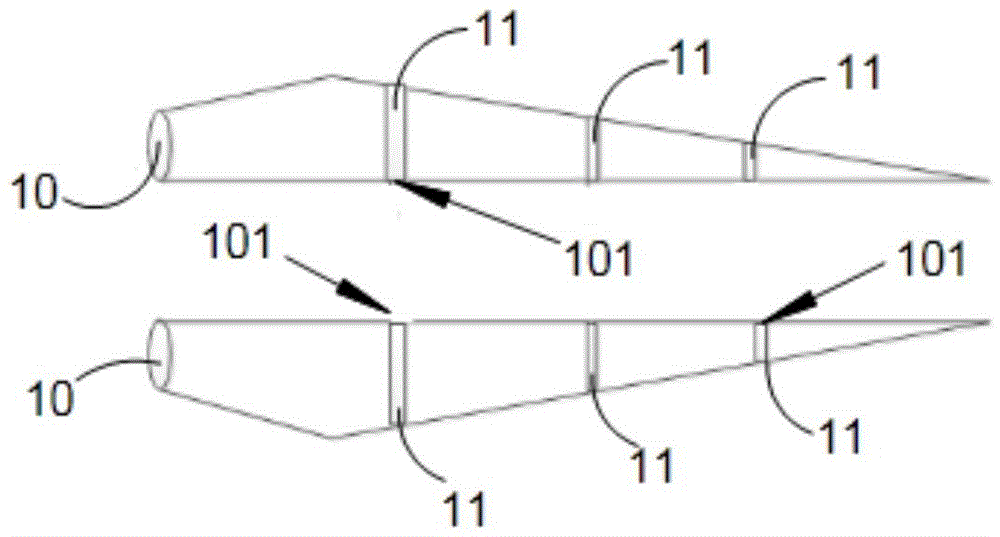

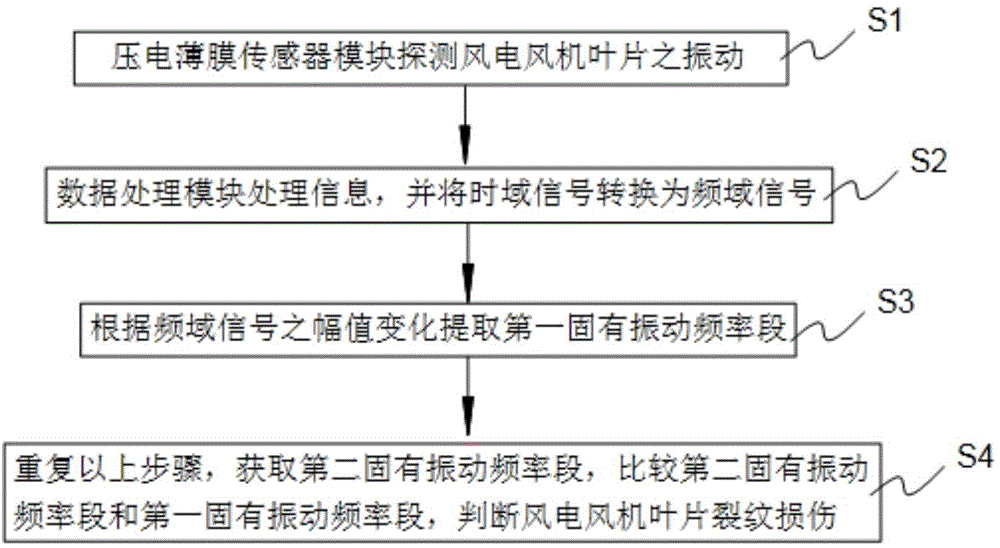

[0026] see figure 1 , figure 1 Shown is a frame structure diagram of the online monitoring device for crack damage of wind turbine blades according to the present invention. The online monitoring device 1 for crack damage of the wind turbine blade includes: a piezoelectric film sensor module 11, the piezoelectric film sensor module 11 is arranged on the wind turbine blade 10, and is connected with a charge amplification module (not shown), A / D conversion module (not shown) is electrically connected with wireless transmitting module 12; The signal of output; Data processing module 14, described data processing module 14 further comprises filter denoising module 141, natural frequency segment extraction module 142, natural frequency dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com