Engine Output Shaft Connecting Device and Its Application Separate Hydraulic Power Unit

A technology of engine output and shaft connection device, applied in the field of engine and hydraulic power, can solve the problems of difficult installation of connecting shaft, limited construction conditions, time-consuming and labor-intensive, etc., to ensure the stability of equipment operation, reduce time and strength, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

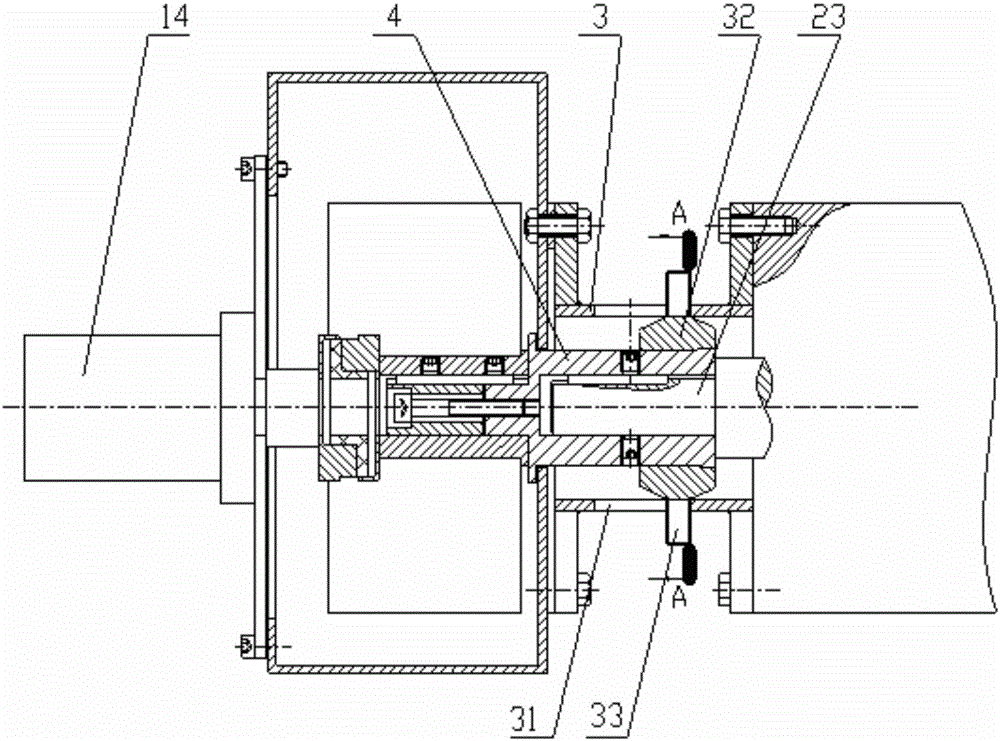

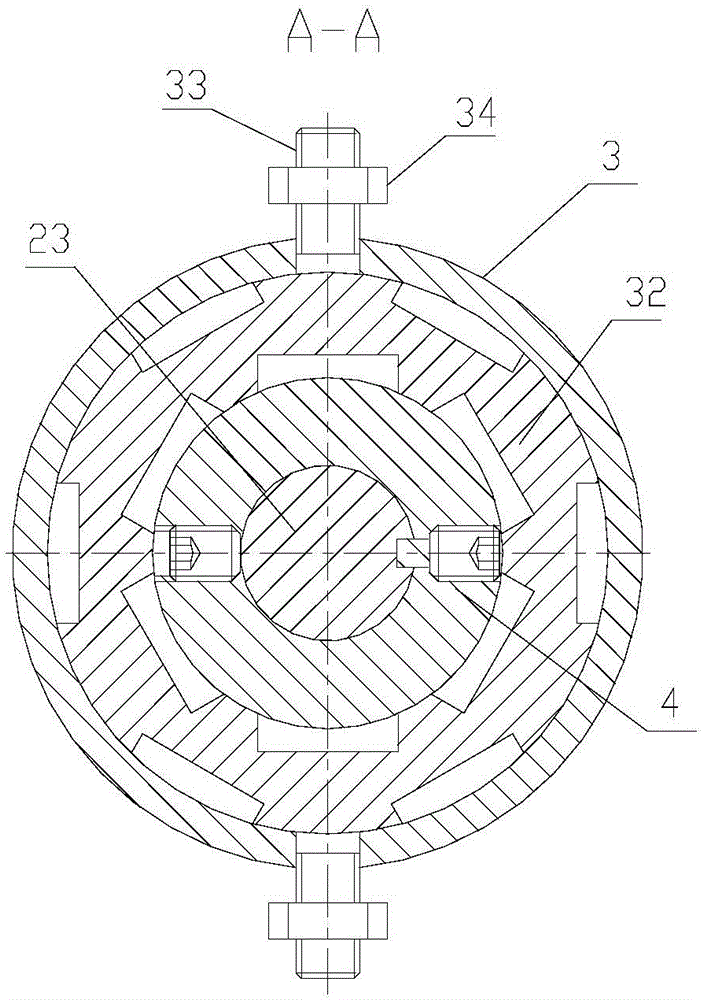

[0029] see figure 1 and figure 2 , a connection device for an engine output shaft, comprising a spacer ring 3, a positioning sleeve 32 and an extension shaft 4; the two ends of the spacer ring 3 are provided with a flange structure, and are fixedly connected to the fixed box wall of the driving part or the shaft of the engine through the flange connection Between the end faces, the engine and drive components are fixed together.

[0030] The extension shaft 4 is arranged in the spacer ring 3 and is coaxial with the spacer ring 3. One end of the extension shaft 4 is coaxially connected with the input shaft of the driving part (hydraulic pump 14), and the other end is a hollow shaft, which is sleeved on the engine through a key connection. On the output shaft 23 ; the positioning sleeve 32 is arranged between the spacer ring 3 and the extension shaft 4 and is coaxial with the spacer ring 3 . Specifically, the diameter of the outer ring of the positioning sleeve 32 is equal to...

Embodiment 2

[0036] In this embodiment, on the basis of Embodiment 1, Embodiment 1 is applied to a separate hydraulic power station, such as Figure 4 and Figure 5 As shown, the engine device 2 of the hydraulic power station is connected to the hydraulic pump of the hydraulic power unit 1 through the engine output shaft connection device disclosed in Embodiment 1, and a spacer ring 3 is provided between the hydraulic power unit 1 and the engine unit 2, and the spacer ring The two ends of 3 are respectively connected with the hydraulic power pack box wall 11 and the engine shaft end face 21 through flanges, one end of the extension shaft 4 of the spacer ring 3 is fixedly connected with the hydraulic pump input shaft of the hydraulic power pack 1, and the other end is hollow The shaft section is socketed with the engine output shaft 23 through a key connection (spline or flat key), and a positioning sleeve is provided between the spacer ring 3 and the extension shaft 4 (see embodiment 1 for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com