Aluminium alloy column-plate node structure used for space structure

A technology of space structure and node structure, which is applied in the direction of building structure and construction, can solve the problems of large number of bolts, unfavorable construction, high project cost, and single node form, so as to achieve fast construction speed, reduce construction difficulty and cost, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

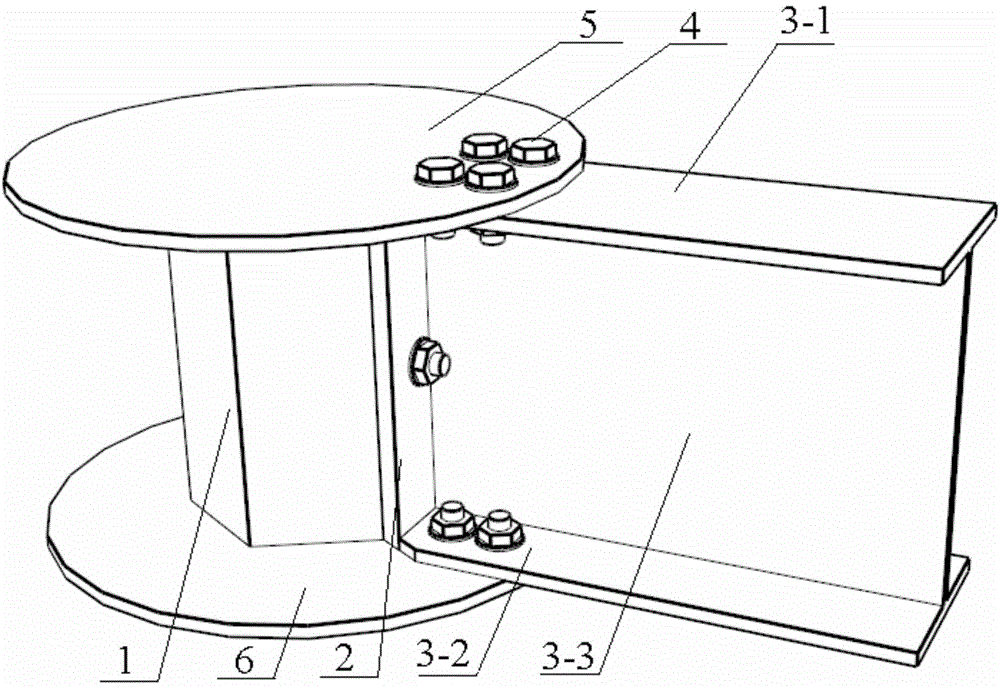

[0007] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the aluminum alloy column-plate node structure for space structure described in this embodiment, which includes a hollow hexagonal column 1, a first cover plate 5, a second cover plate 6, six connecting workpieces 3, six connecting pieces Plate 2 and a plurality of fasteners 4, the vertical plate 3-3 is installed between the upper plate 3-1 and the lower plate 3-2, the first cover plate 5 is horizontally arranged on the top of the hollow hexagonal column 1, the second cover plate 6 Horizontally arranged at the lower end of the hollow hexagonal prism 1, the centerline of the hollow hexagonal prism 1 along the length direction coincides with the centerline of the first cover plate 5 and the centerline of the second cover plate 6 respectively, and the six connecting plates 2 pass through a plurality of tight The fasteners 4 are installed on the six sides of the hollow hexagonal prism 1, ...

specific Embodiment approach 2

[0008] Specific embodiment two: combine Figure 1-Figure 2 Describe this embodiment, the aluminum alloy column-plate node structure for space structure described in this embodiment, each connecting plate 2 is vertically fixed and installed on one side of the hollow hexagonal column 1 through two fasteners 4, And the two fasteners 4 are arranged horizontally, and the two fasteners 4 are arranged horizontally. Others are the same as the first embodiment.

specific Embodiment approach 3

[0009] Specific embodiment three: combine Figure 1-Figure 2 Describe this embodiment, the aluminum alloy column-plate node structure used for space structures described in this embodiment, the connecting workpiece 3 is a workpiece with an H-shaped cross section, and the connecting workpiece 3 and the first top end are connected through the H-shaped workpiece. The connection nodes between the cover plate 5 and the second cover plate 6 at the bottom end are uniform, and the tensile and compressive properties are enhanced, and the others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com