A cable for electric vehicle charging pile and its manufacturing method

A technology of electric vehicles and production methods, which is applied in the field of cables, can solve problems such as poor pullability and bending resistance, and achieve the effects of improving tensile and compressive resistance, improving service life and safety, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

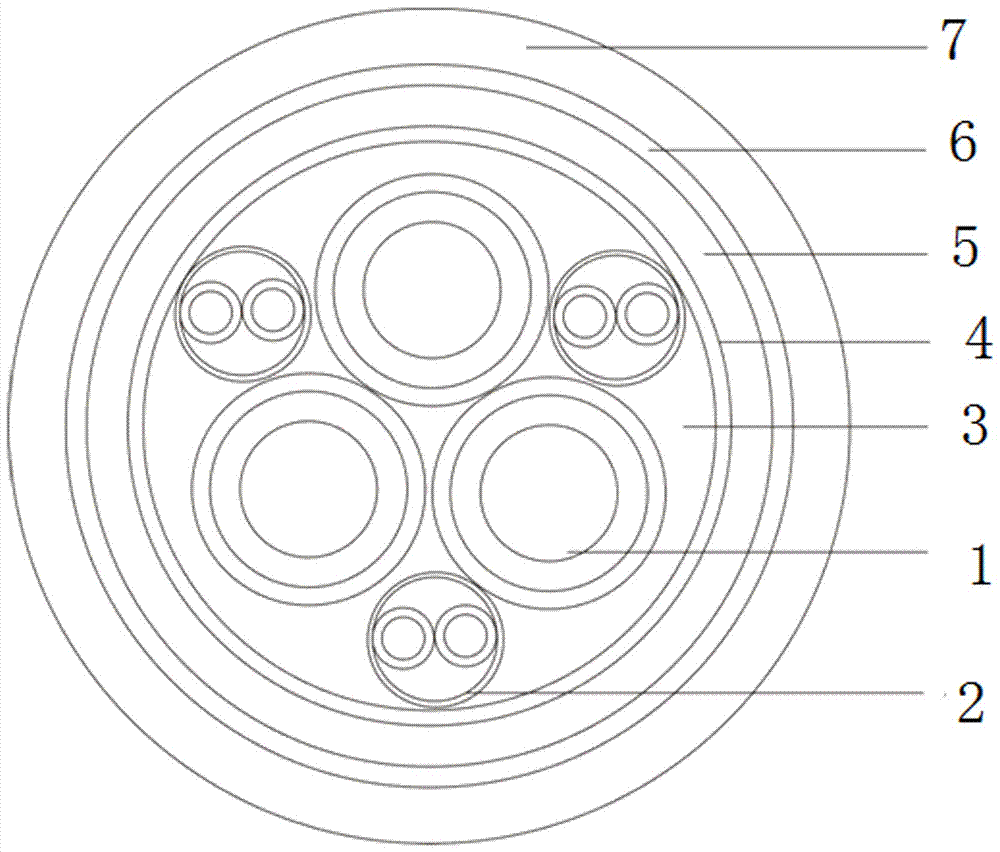

Embodiment 1

[0026] The manufacturing process of the present invention is as follows:

[0027] 1. Conductor stranding.

[0028] For the charging core and signal core, flexible fine copper wire conductors are used, and the conductor diameter is 0.15mm-0.2mm. In order to increase the bending resistance and tensile performance of the conductor, three steel wires of the same specification are added to make the conductor structure dense, thereby reducing outer diameter, reducing costs.

[0029] 2. Insulation extruded package.

[0030] The insulating layer is insulated with ethylene propylene rubber. The long-term allowable working temperature of the cable is -40~125°C. It is a saturated non-polar material with high aging resistance: ozone resistance and high thermal stability. (The weight loss temperature of natural rubber is 315°C in a nitrogen environment. Styrene butadiene rubber is 391 ℃, EPDM rubber is 485 ℃) good heat aging resistance, excellent weather resistance, excellent chemical r...

Embodiment 2

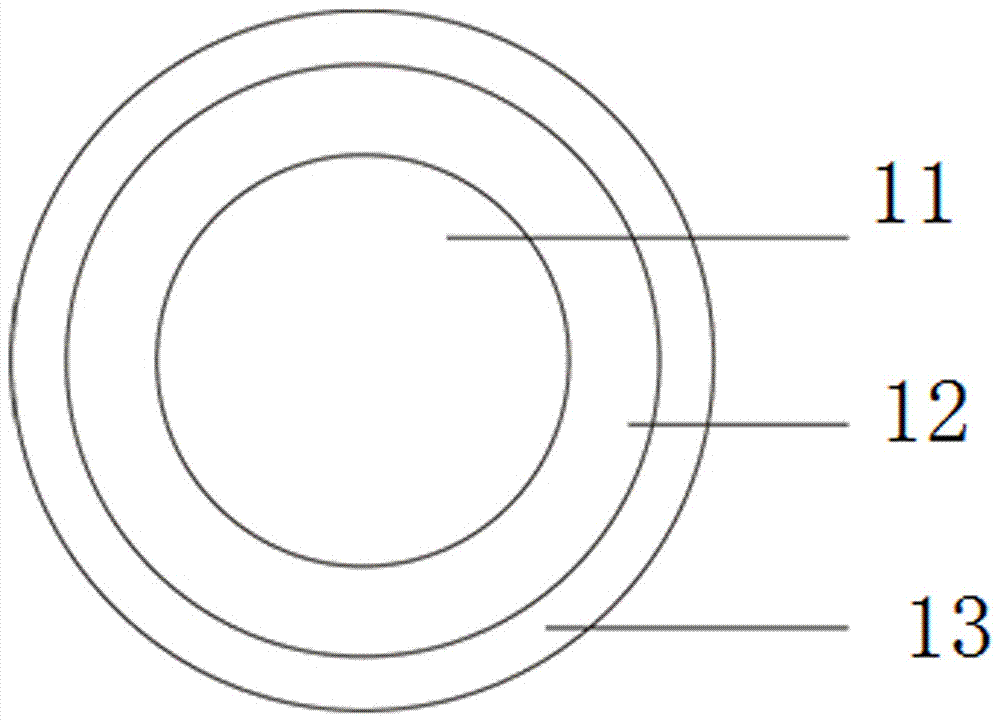

[0044] The first choice is to make the charging wire core, wrap the charging insulation layer around the copper wire conductor, and then wrap a charging slip layer outside the charging insulation layer, wherein the charging conductor is a copper wire conductor with a conductor diameter of 0.18mm, and the charging wire core The charging insulation layer is made of ethylene propylene rubber, the thickness of the charging insulation layer is 0.10-0.15mm, the charging slip layer is wrapped with polyester tape, and the thickness of the charging slip layer is 0.19mm;

[0045] Next, make the signal core, using two copper wire conductors with the same diameter as a group, each copper wire conductor is wrapped with a signal insulation layer on the surface, and then a shielding layer is wrapped around the signal insulation layer of the two copper wire conductors The two sets of signal conductors are made of copper wire conductors wrapped around the outside of the signal insulation layer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com