High-throughput screening method for grape wine brewing microorganisms

A screening method and microbial technology, applied in the field of wine brewing, can solve the problems of time-consuming and labor-consuming, and achieve the effect of reducing workload and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

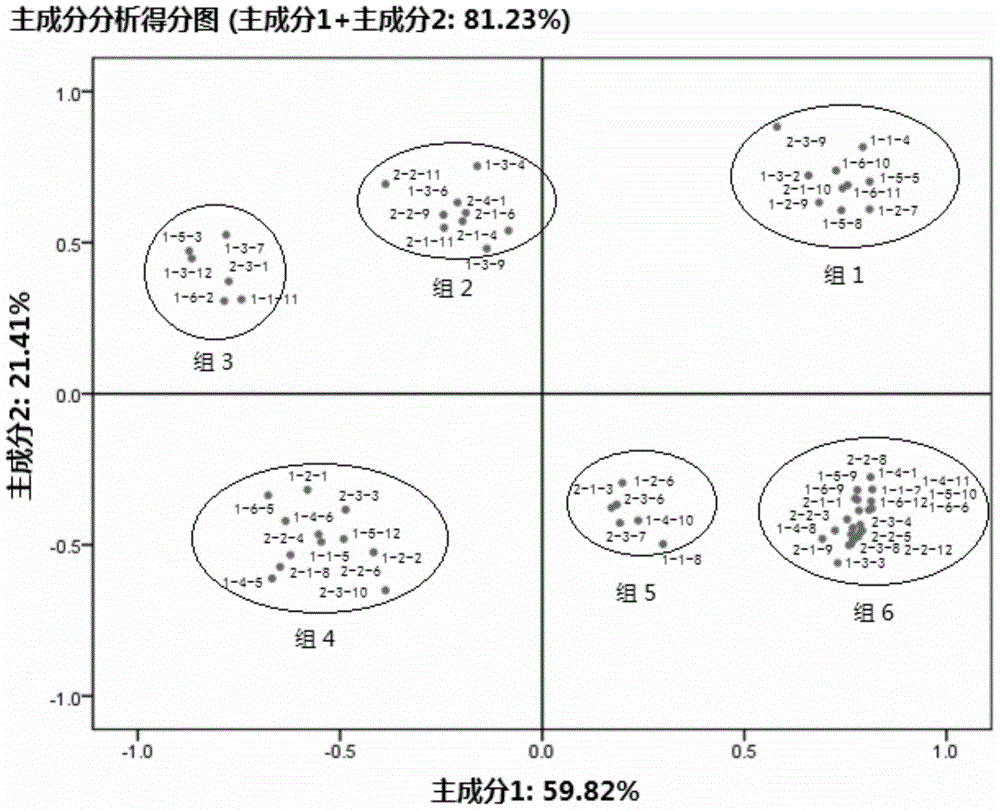

Embodiment 1

[0083] The wine grape sample is a Cabernet Sauvignon grape sample collected from the Hebei production area in 2013. The reducing sugar content in the grape juice is 227.12g / L, the total acid (calculated as tartaric acid) is 8.23g / L, and the total available nitrogen is 306.72 mg / L, pH 3.42. During the sample collection process, all instruments were aseptically treated, and the collected grape samples were placed in a portable fresh-keeping box at 4°C and quickly brought back to the laboratory for processing. The treatment method is: crush 1500g of grape samples, put them into a 2.5L small-scale stainless steel wine fermentation equipment after crushing, add 60mg / L of SO 2 , at 25°C for natural fermentation with the skin on. The total mass of the entire fermentation system was measured before fermentation. During the entire fermentation process, the residual sugar content in the fermentation broth was measured every 6 hours. After 10 days of fermentation, the residual sugar con...

Embodiment 2

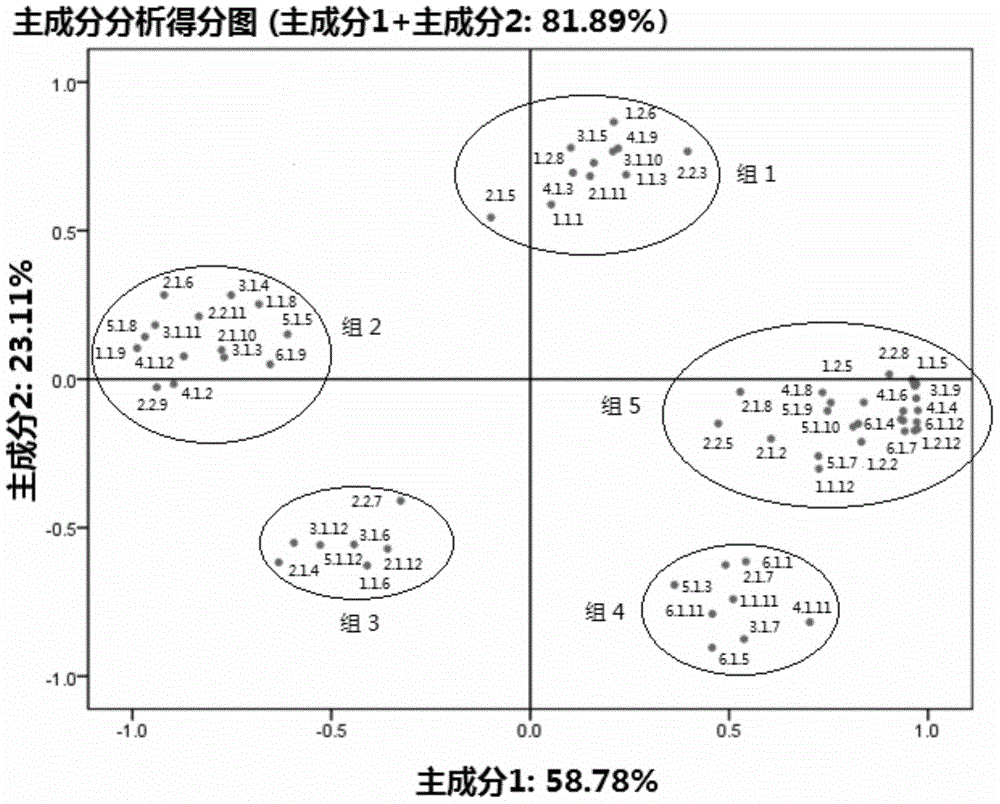

[0093] The fermented liquid obtained after the natural alcoholic fermentation of the Cabernet Sauvignon grape sample collected from the Hebei production area in 2013 in Example 1 was used as a sample to continue the natural malolactic fermentation. The main physical and chemical indicators in the fermented liquid obtained after natural alcoholic fermentation are as follows: alcohol content is 12.1% (v / v), residual sugar (calculated as glucose) content is 3.98g / L, total acid (calculated as tartaric acid) content is 8.47 g / L, the content of malic acid is 4.56g / L, and the pH is 3.45. Under the condition of 22 ℃, carry out natural fermentation with skin. During the whole fermentation process, the content of malic acid in the fermentation broth was measured every 24 hours with the malic acid enzyme detection kit. After 10 days of malolactic fermentation, the residual sugar content dropped to 2.08g / L and the malic acid content dropped to 1.09g / L, shake the fermented liquid evenly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com