Construction site water recovery and recycling system comprehensive purification tank and manufacturing method thereof

A technology for construction sites and purification pools, applied in waterway systems, construction materials processing, chemical instruments and methods, etc., can solve problems such as wasting water resources, reduce municipal water use, facilitate promotion, and solve recycling problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

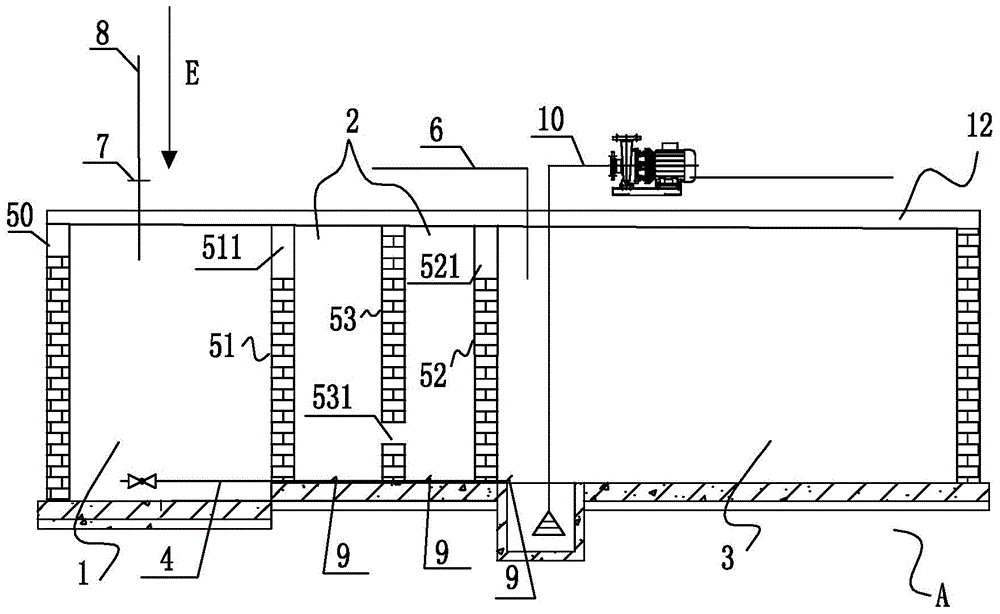

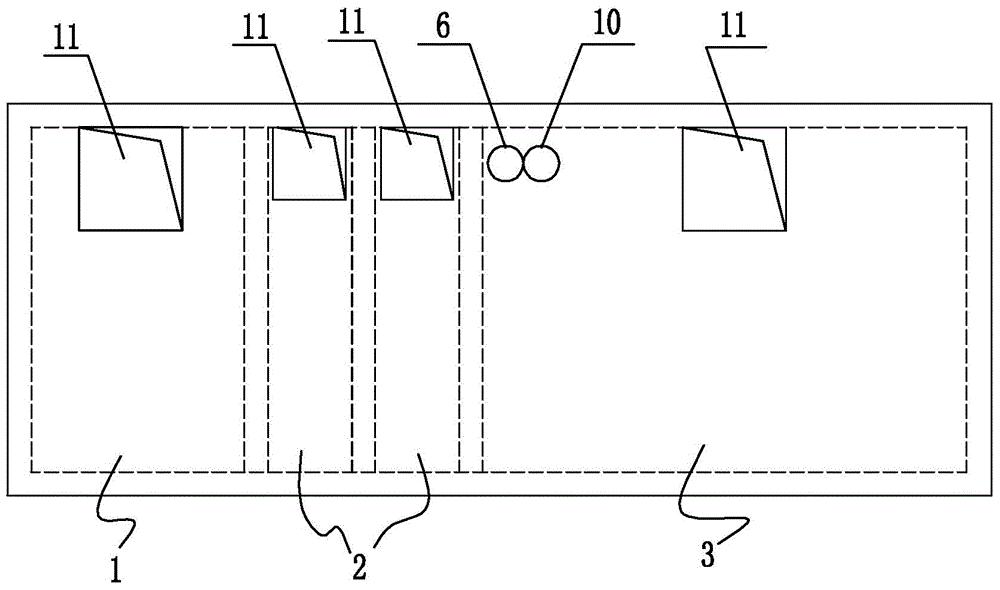

[0053] A comprehensive purification pool for water recovery and recycling systems on construction sites, such as figure 1 As shown, the purification tank is divided into sedimentation tank 1, grease trap 2 and reservoir 3 by partition wall I and partition wall II, and the overflow hole between sedimentation tank 1, grease trap 2 and reservoir 3 Interconnected; the overflow hole I511 connecting the sedimentation tank 1 and the grease trap 2 is set on the upper part of the partition wall I51 between the sedimentation tank 1 and the grease trap 2; the overflow hole connecting the grease trap 2 and the reservoir 3 II521 is arranged on the upper part of the partition wall II52 between the grease trap 2 and the reservoir 3; the middle partition wall 53 is arranged inside the grease trap 2, and the overflow hole III531 is arranged at the middle and lower part of the middle partition wall 53;

[0054] Sedimentation tank 1 can sink impurities such as silt, sand, and other heavy particl...

Embodiment 2

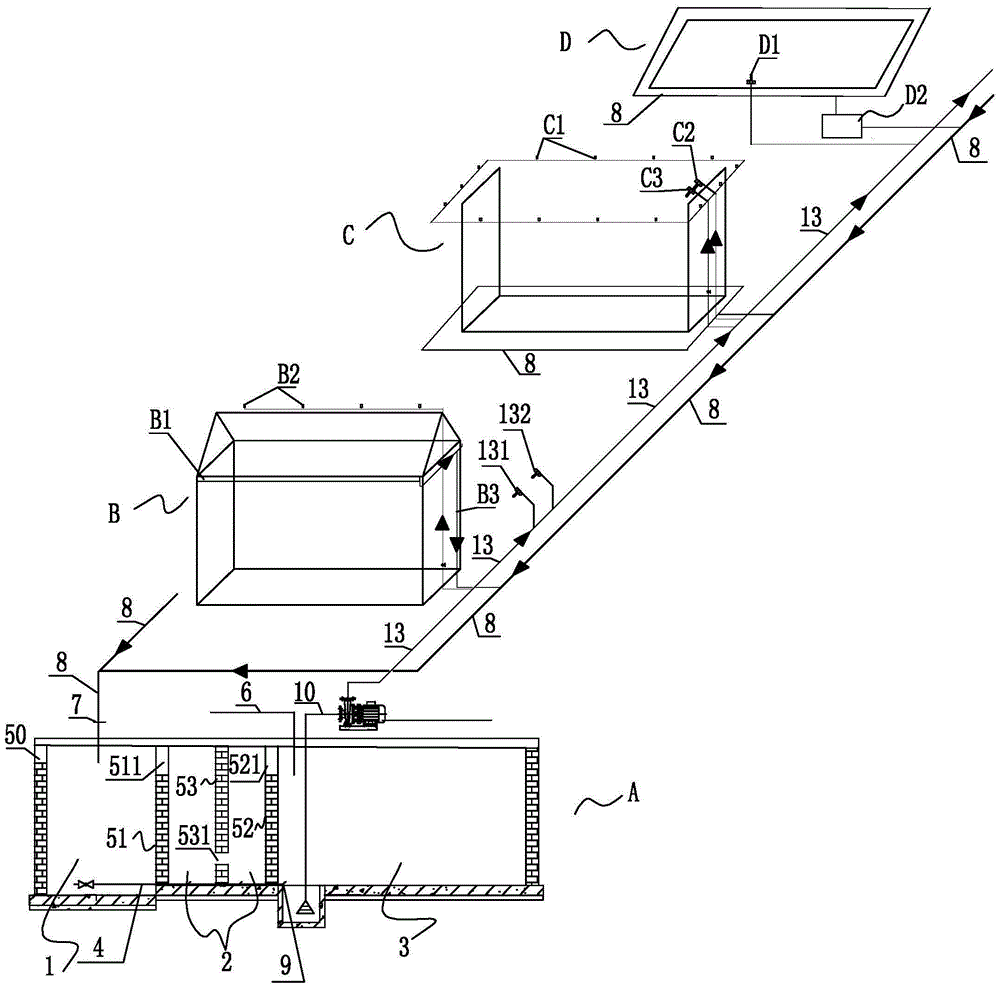

[0059] A kind of construction site water recovery and recycling system, such as image 3 As shown, the construction site water recovery and recycling system includes a comprehensive purification pool A, connecting prefabricated house B, proposed building C, flushing platform D waste water, construction site waste water ditch 8, water supply pipe 13, rain water, construction site waste water ditch 8. The outlet is connected to the comprehensive purification tank A; the comprehensive purification tank A is a comprehensive purification tank of a construction site water recovery and recycling system described in Embodiment 1;

[0060] The comprehensive purification tank A is divided into a sedimentation tank 1, a grease trap 2 and a reservoir 3 through a partition wall, and the sedimentation tank 1, grease trap 2 and reservoir 3 are connected to each other through an overflow hole; The overflow hole I511 of the sedimentation tank 1 and the grease trap 2 is set on the upper part of...

Embodiment 3

[0065] The manufacturing method of the comprehensive purification tank of the construction site water recovery and recycling system of the present invention is the production method of the comprehensive purification tank of the construction site water recovery and recycling system described in Embodiment 1. The specific method is:

[0066] A. Calculate the total water consumption Q of the construction site according to the requirements of the temporary water use plan for the construction of the proposed project, and determine the size of the reservoir accordingly:

[0067] Q=q 4 +(q 1 +q 2 +q 3 ) / 2 when: (q 1 +q 2 +q 3 )≤q 4

[0068] Q= (q 1 +q 2 +q 3 ) when: (q 1 +q 2 +q 3 )>q 4 ;

[0069] In the above formula:

[0070] Q-total water consumption of the construction site,

[0071] q 1 - water consumption of construction site,

[0072] q 2 - water consumption of construction machinery,

[0073] q 3 - domestic water consumption at the construction site, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com