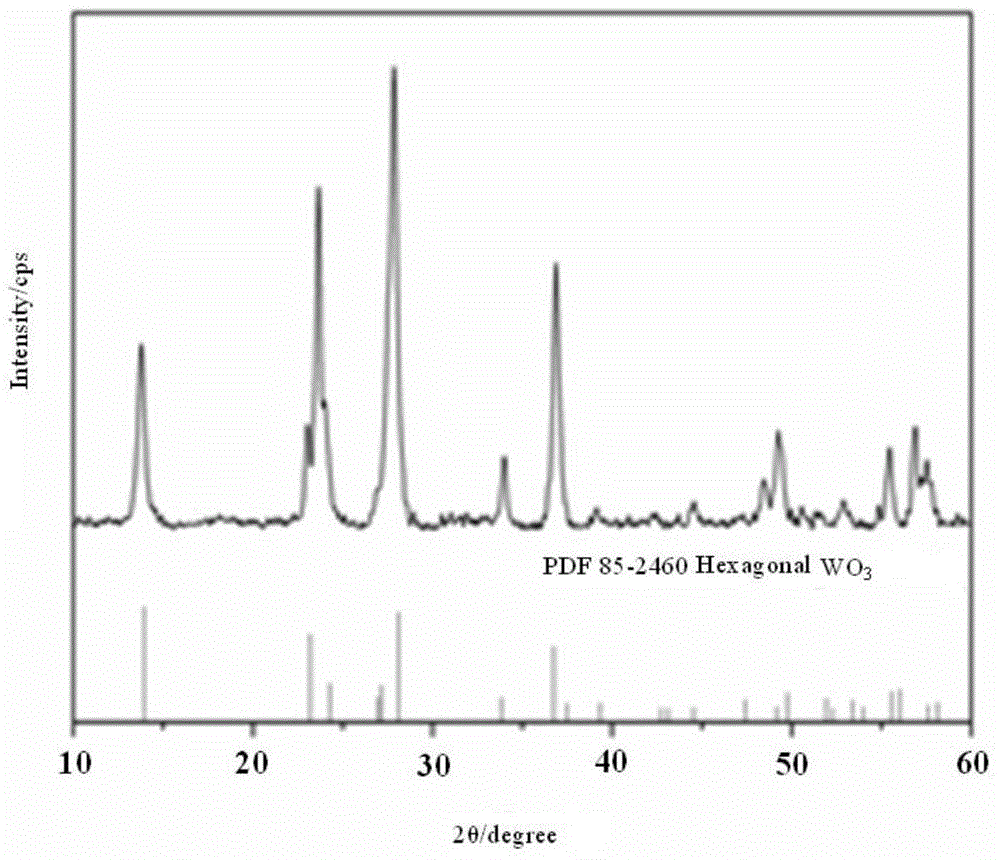

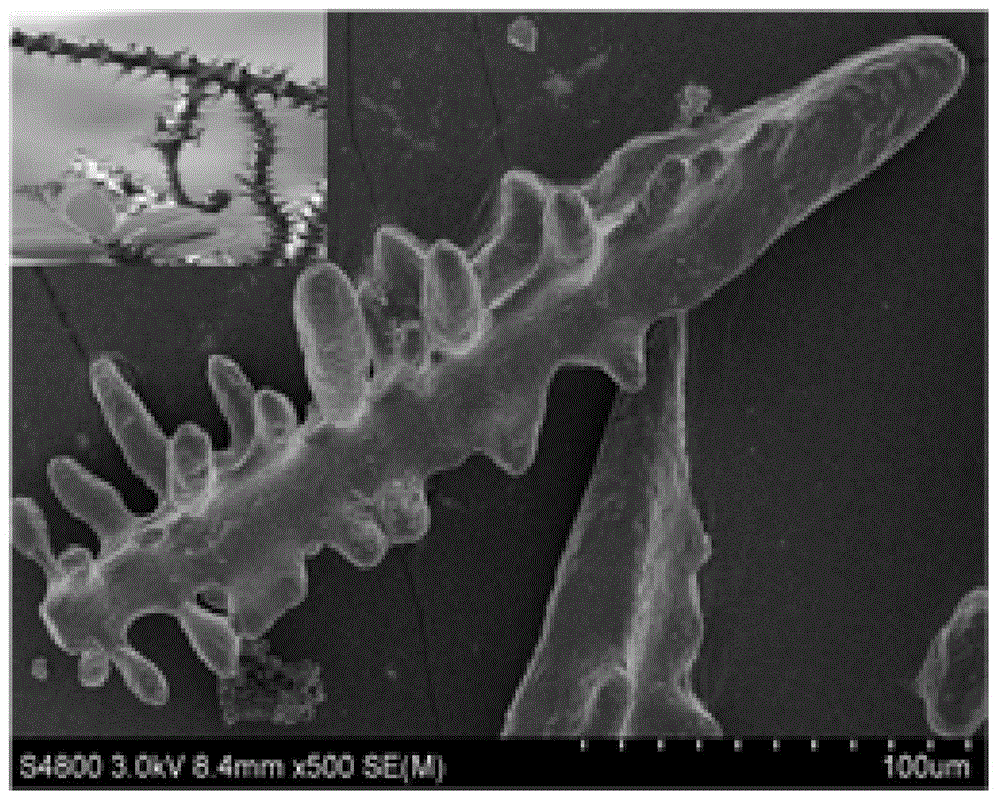

Preparation method of one-dimensional Euphorbia-milii-shaped WO3 microcrystal

A technology of thorn plum and microcrystal, which is applied in the field of preparing one-dimensional thorn plum-like WO3 microcrystal, can solve the process conditions and structure design of powder easy to agglomerate, difficult to obtain oriented growth one-dimensional nanomaterials, microwave-assisted solvothermal The problem of fast reaction rate, etc., achieves the effect of being conducive to rapid diffusion and mass transfer, single oriented growth morphology, and controllable morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Add analytically pure WCl 6 Add in the mixed solvent of isopropanol and distilled water, the volume ratio of control solvent isopropanol and distilled water is V 异丙醇 :V 水 =1:1, and keep stirring until WCl 6 dissolved to produce W 6+ A solution with a concentration of 0.06mol / L;

[0023] Step 2: Add analytically pure polyoxyethylene polyoxypropylene block copolymer (F127) to the above solution, control the addition of polyoxyethylene polyoxypropylene block copolymer to 20g / L, and heat at 45°C stirring to fully dissolve the polyoxyethylene polyoxypropylene block copolymer to obtain a precursor solution;

[0024] Step 3: Pour the precursor solution into the hydrothermal kettle, control the filling degree at 60%, then seal the hydrothermal kettle, put the sealed hydrothermal kettle into the homogeneous reactor, and control the solvent heating temperature to 160 ℃, the rotation speed is 40r / min (the hydrothermal kettle rotates around a fixed axis during the heat...

Embodiment 2

[0028] Step 1: Add analytically pure WCl 6 Add in the mixed solvent of isopropanol and distilled water, the volume ratio of control solvent isopropanol and distilled water is V 异丙醇 :V 水 =3:2, keep stirring until WCl 6 dissolved to produce W 6+ A solution with a concentration of 0.01mol / L;

[0029] Step 2: Add analytically pure polyoxyethylene polyoxypropylene block copolymer (F127) to the above solution, control the addition of polyoxyethylene polyoxypropylene block copolymer to 15g / L, and heat at 40°C stirring to fully dissolve the polyoxyethylene polyoxypropylene block copolymer to obtain a precursor solution;

[0030] Step 3: Pour the precursor solution into the hydrothermal kettle, control the filling degree at 65%, then seal the hydrothermal kettle, put the sealed hydrothermal kettle into the homogeneous reactor, and control the solvent heating temperature to 140 ℃, the rotation speed is 30r / min (the hydrothermal kettle rotates around a fixed axis during the heat pre...

Embodiment 3

[0034] Step 1: Add analytically pure WCl 6 Add in the mixed solvent of isopropanol and distilled water, the volume ratio of control solvent isopropanol and distilled water is V 异丙醇 :V 水 =4:1, keep stirring until WCl 6 dissolved to produce W 6+ A solution with a concentration of 0.005mol / L;

[0035] Step 2: Add analytically pure polyoxyethylene polyoxypropylene block copolymer (F127) to the above solution, control the addition amount of polyoxyethylene polyoxypropylene block copolymer to 5g / L, and heat at 35°C stirring to fully dissolve the polyoxyethylene polyoxypropylene block copolymer to obtain a precursor solution;

[0036] Step 3: Pour the precursor solution into the hydrothermal kettle, control the filling degree at 70%, then seal the hydrothermal kettle, put the sealed hydrothermal kettle into the homogeneous reactor, and control the solvent heat temperature to 120 ℃, the rotation speed is 20r / min (the hydrothermal kettle rotates around a fixed axis during the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com