Annular superabrasive wire and manufacturing method thereof

A technology of superabrasives and a manufacturing method, applied in the fields of semiconductor and non-conductor cutting tools and precious metals, can solve the problem of the end of the service life of the annular superabrasive wire, the low fatigue resistance of the annular superabrasive wire, and the poor quality of the cutting surface, etc. problems, to achieve the effect of good cutting surface quality, improved service life and narrow slits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail, to better understand content of the present invention.

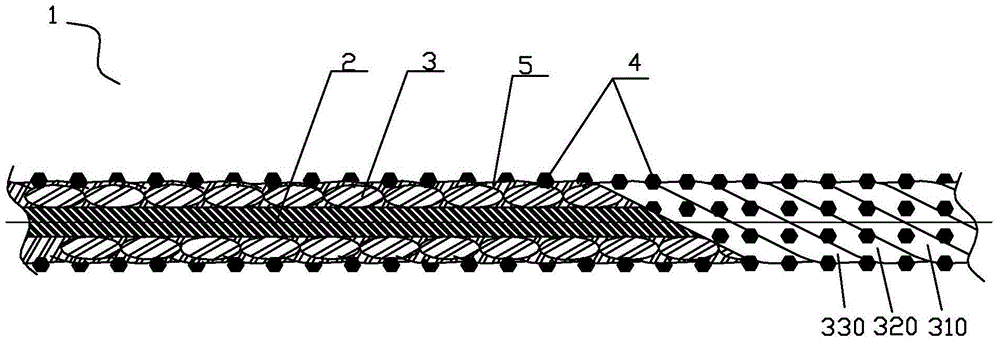

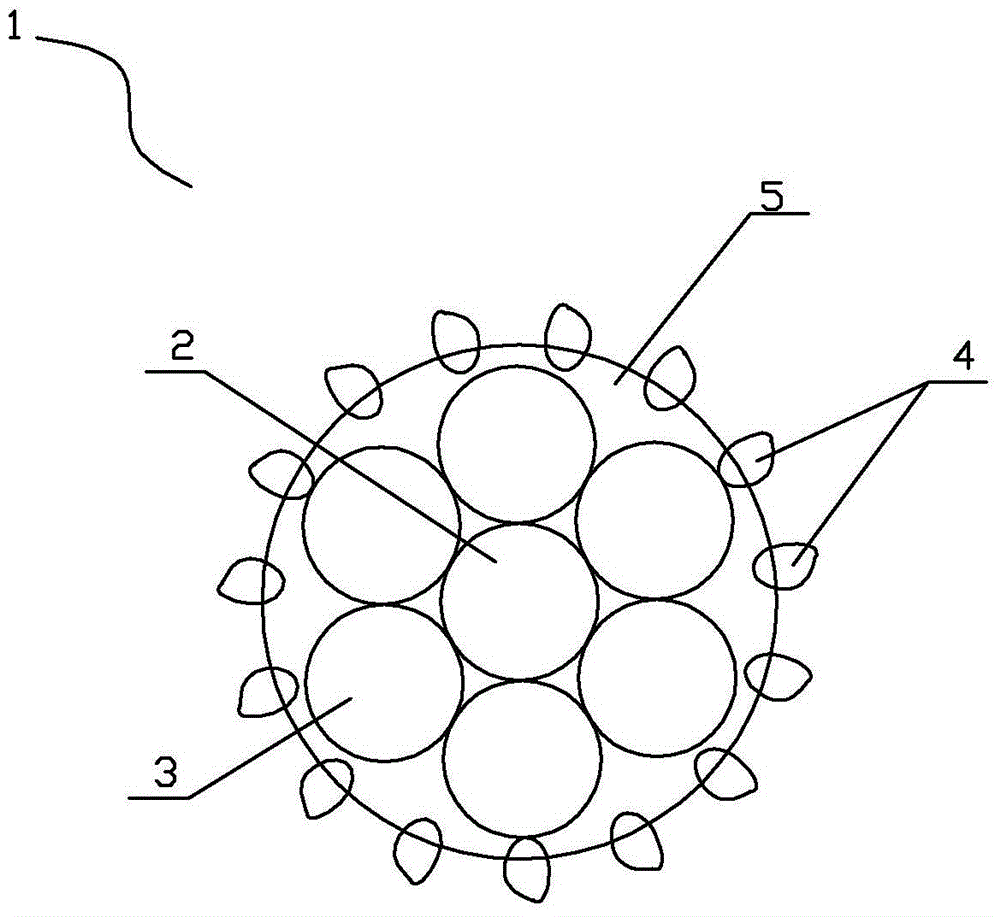

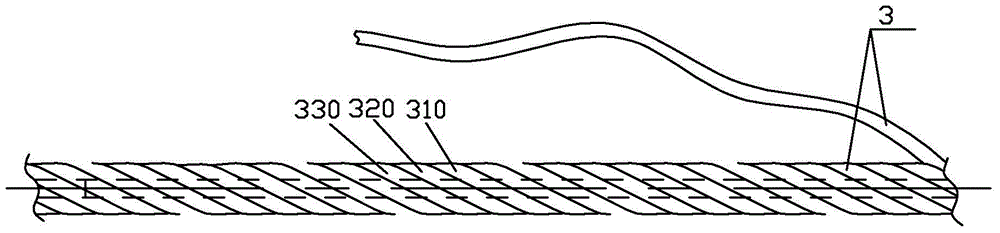

[0032] The annular superabrasive wire 1 of the present invention has a base body of a wire rope with a diameter of 0.1 mm to 6 mm, and the wire rope includes a core wire 2 and a strand wound on the core wire 2 in a helical manner 3 (i.e. 1×1 rope), the end-to-end connection of the core wire 2 forms a ring shape, and the length of the strand 3 wound on the core wire 2 is to meet the length of its winding 6 turns on the core wire 2 , after the strand 3 is wound 6 times on the core wire 2, it is connected end to end to form a circular silk rope (the joint of the strand 3 is located on one side of the connection point of the core wire 2); wherein, the strand 3 Winding 6 circles on the core wire 2 refers to taking the core wire 2 as the axis, pulling the head end of the strand 3 from a certain place on the core wire 2 (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com