Strong Casting Process of Aluminum Alloy Wheel

A technology for aluminum alloys and wheels, applied in the field of light alloy forming, can solve problems such as unfavorable batch production, unable to discharge aluminum liquid smoothly, and no cooling control principle, so as to improve production efficiency, shorten die-casting time, and reduce de-gate process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation will be described in detail below in conjunction with the accompanying drawings (this embodiment is a further description of the present invention, rather than any limitation to the present invention).

[0028] combined with figure 1 Explain the implementation rules, taking a 16X6.5-inch aluminum alloy wheel as an example, the casting process using this process is:

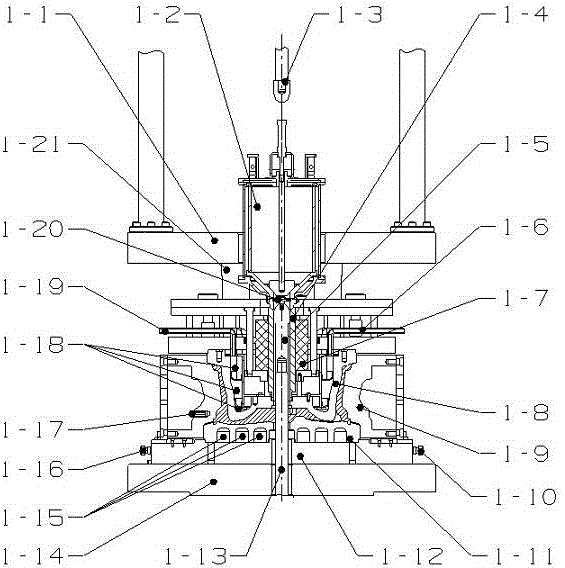

[0029] (1) First preheat the mold, the mold preheating temperature is 280°C, the aluminum alloy material is A356, and the heating temperature of the aluminum liquid is 700°C, such as figure 1 As shown, the casting mold is first installed on the casting machine before work, the upper mold (1-8) and the top plate of the mold are connected with the casting machine slider (1-1) through the connecting pillar (1-21), and the bottom mold (1-1 -11) Installed on the upper side of the casting machine table (1-14) through the mold bottom plate (1-12), and the side mold (1-9) is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com