Lithium-sulfur battery composite positive electrode material and preparation method thereof

A composite positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., to improve cycle performance, reduce energy density loss, and ensure high-efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

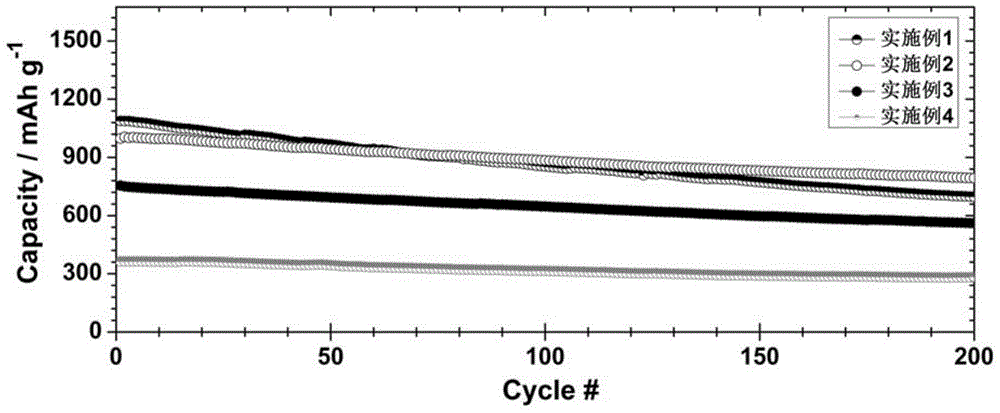

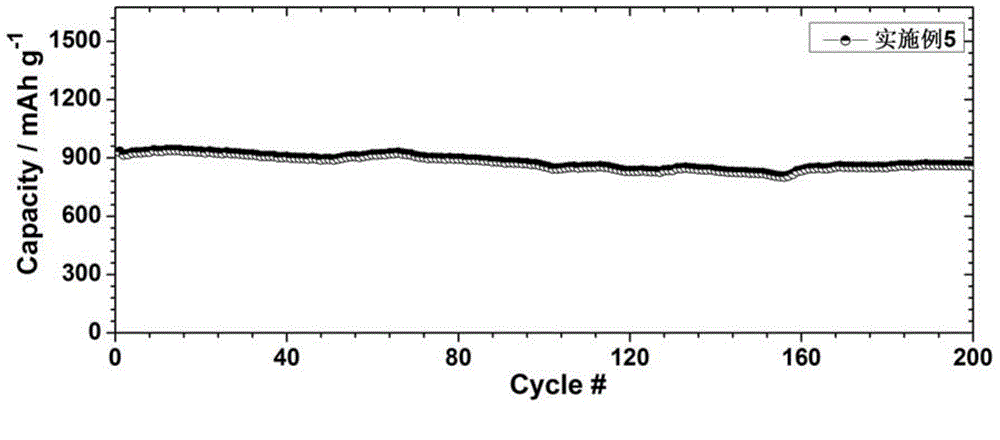

[0050] Prepare a porous multi-walled carbon nanotube / sulfur / glucose composite positive electrode material with glucose as a modifier, wherein the amount of each component is calculated by mass percentage: conductive agent porous multi-walled carbon nanotube 50wt%, electrochemically active substance sulfur 49.9wt%, modifier glucose 0.1wt%.

[0051] The preparation method of above-mentioned porous multi-wall carbon nanotube is: the potassium hydroxide of solid state and carbon material multi-wall carbon nanotube (aperture is 2-5nm, specific surface area is 324m 2 / g, the pore volume is 0.40cm 3 / g, sold by Nanjing Xianfeng Nano Material Technology Co., Ltd.) uniformly mixed with a mass ratio of 5:1, then placed in a tube furnace, with a mixed gas of hydrogen and nitrogen as a protective atmosphere, wherein the hydrogen volume concentration is 5% , calcined at 850° C. for 1.5 h, then the calcined product was taken out, washed with 1 mol / L dilute hydrochloric acid and then washed...

Embodiment 2

[0059] Prepare a porous multi-walled carbon nanotube / sulfur / glucose composite positive electrode material with glucose as a modifier, wherein the amount of each component is calculated by mass percentage: conductive agent porous multi-walled carbon nanotube 59.4wt%, electrochemical active substance Sulfur 40wt%, modifier glucose 0.6wt%.

[0060] The preparation method of above-mentioned porous multi-wall carbon nanotube is: the potassium hydroxide of solid and multi-wall carbon nanotube (aperture is 2-5nm, specific surface area is 324m 2 / g, the pore volume is 0.40cm 3 / g, sold by Nanjing Xianfeng Nano Material Technology Co., Ltd.) uniformly mixed with a mass ratio of 5:1, then placed in a tube furnace, with a mixed gas of hydrogen and nitrogen as a protective atmosphere, wherein the hydrogen volume concentration is 5% , calcined at 650°C for 1.5h, then the calcined product was taken out, washed with dilute hydrochloric acid and then washed with deionized water until neutral...

Embodiment 3

[0068] Preparation of porous multi-walled carbon nanotubes / sulfur / glucose composite positive electrode material with glucose as a modifier, the method is similar to Example 1, the difference is that the amount of each component is calculated by mass percentage: conductive agent porous multi-walled carbon nano Tube 50wt%, electrochemical active substance sulfur 49.2wt%, modifier glucose 0.8wt%.

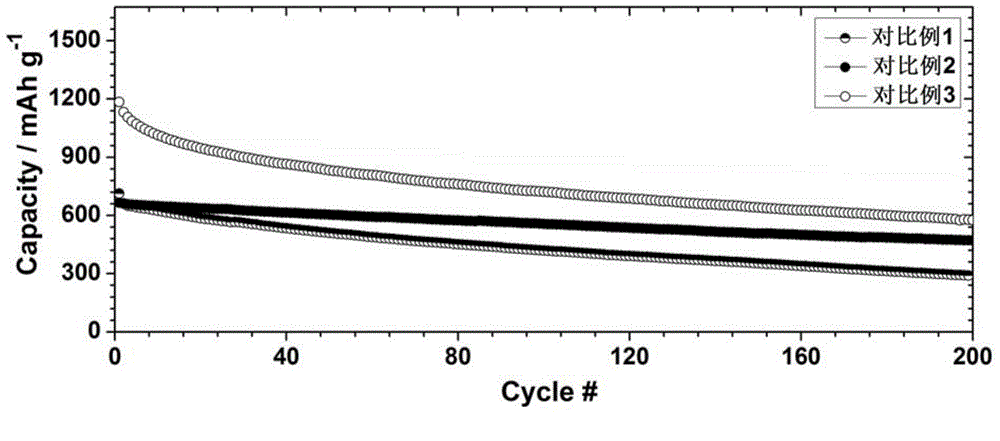

[0069] In this example, the preparation of the composite positive electrode material, the preparation of the positive electrode sheet, the method of assembling the battery, and the battery test are all the same as in Example 1. The battery charge and discharge test results show that: under the 1C rate, the first charge and discharge of the battery prepared in this example The specific capacity is 754mAh / g, and the specific capacity after 200 cycles is 561mAh / g. The discharge cycle test diagram of the battery is as follows figure 2 shown. Compared with Example 2, the increase of gluco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com