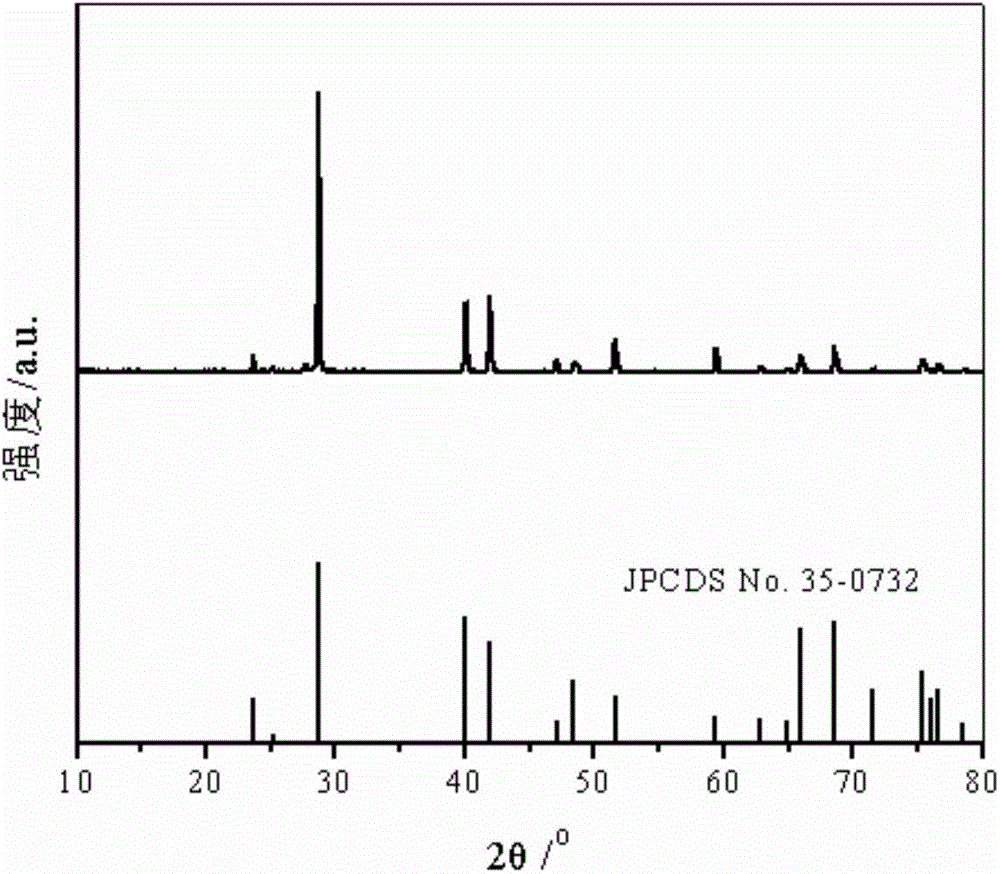

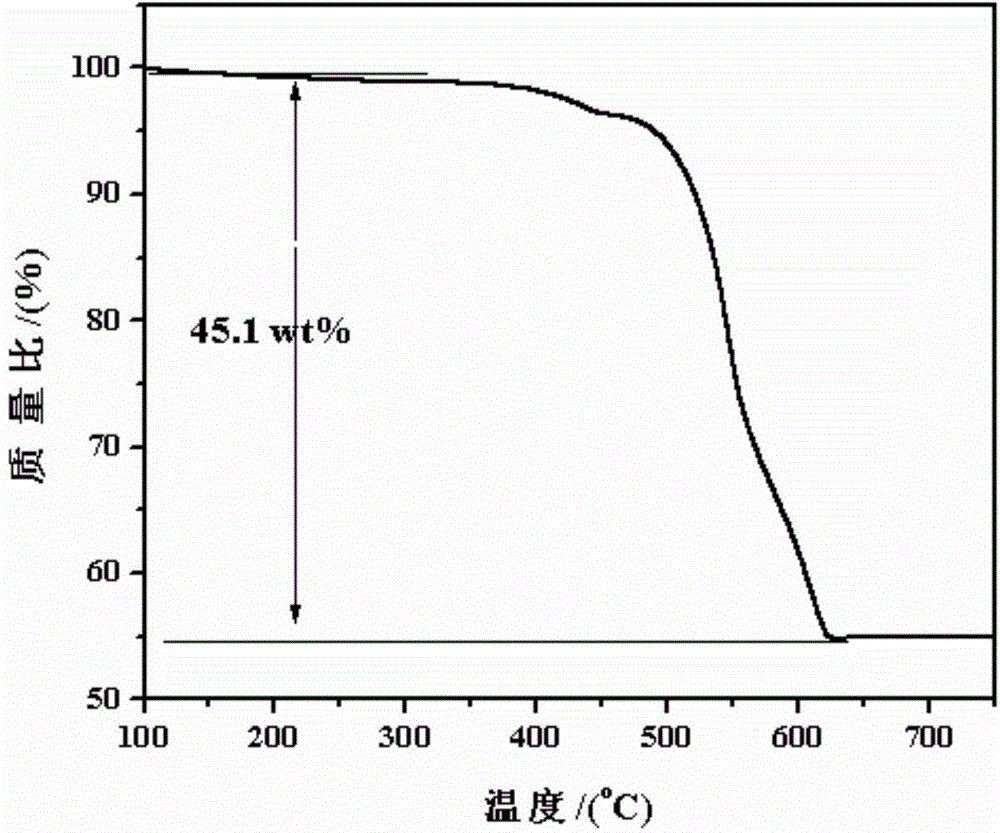

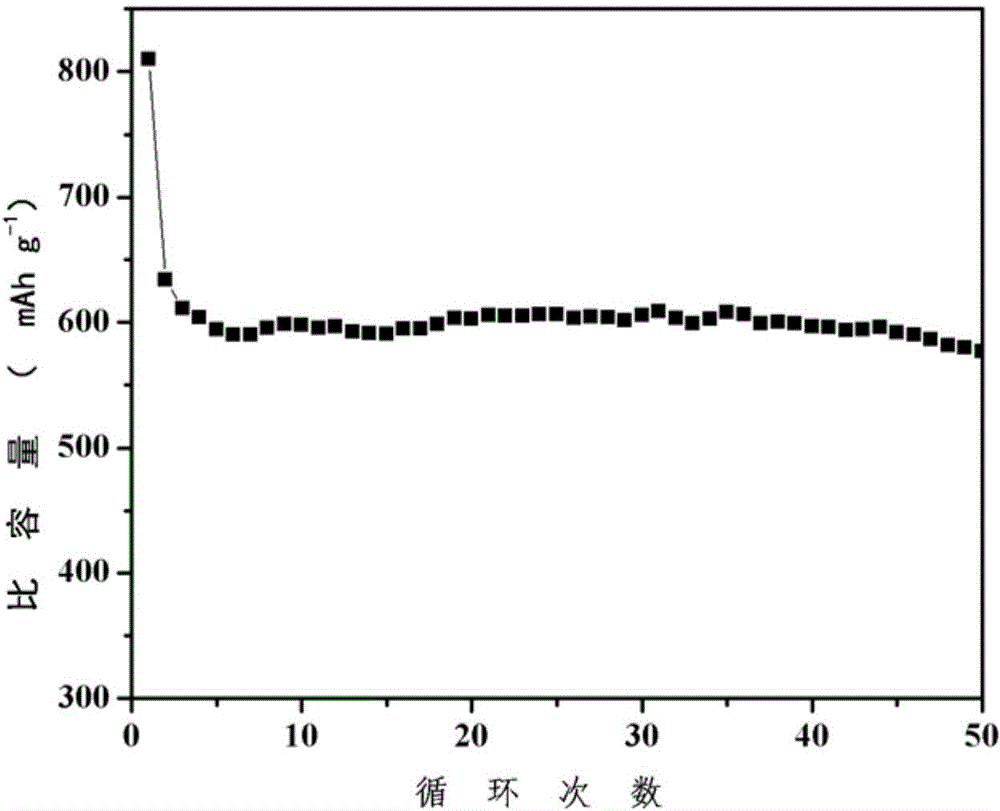

Preparation method for sodium-ion battery antimony/carbon anode composite material with yolk-shell structure

A technology of sodium ion battery and composite material, applied in the field of preparation of negative electrode material of sodium ion battery, can solve the problem of inability to effectively suppress the volume expansion of antimony, achieve good thermal stability and mechanical properties, good mechanical stability, and improve electronic conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]Weigh 2 g of antimony trichloride and add it into deionized water, and stir at room temperature to form a clear solution A. In addition, 1.4 g of sodium borohydride and 6 g of sodium hydroxide were weighed and dissolved in deionized water to obtain solution B. Under the condition of stirring, at a temperature of 60° C., solution B was dropped into solution A drop by drop, and the stirring was continued for 1 h. Then centrifuge and wash to obtain nano-antimony particles; add 1 g of nano-antimony particles prepared into a mixed solution of 50 mL of deionized water, 100 mL of absolute ethanol and 3 mL of 30wt.% ammonia water, ultrasonically treat for 1 h, and measure 0.8 g of ethyl orthosilicate Drop into it and stir at 30°C for 5h. Centrifugal cleaning to obtain the antimony silica core-shell structure; weigh 1g of dopamine hydrochloride and dissolve it in deionized water, add 1.5g of antimony silica, ultrasonically disperse for 1 hour, and adjust the pH of the solution t...

Embodiment 2

[0041] Weigh 2 g of antimony nitrate and add it into deionized water, stir at room temperature to form a clear solution A. In addition, 1.4 g of sodium borohydride and 6 g of sodium hydroxide were weighed and dissolved in deionized water to obtain solution B. Under the condition of stirring, at a temperature of 100° C., solution B was dropped into solution A drop by drop, and the stirring was continued for 1 h. Then centrifuge and wash to obtain nanometer antimony particles; add 1g of nanometer antimony particles to 50mL of deionized water, 90mL of absolute ethanol and 5mL of 25wt.% ammonia solution, sonicate for 1.5h, and measure 0.8g of ethyl orthosilicate Ester was added dropwise and stirred at 30°C for 10h. Centrifugal cleaning to obtain the antimony silica core-shell structure; weigh 1g of dopamine hydrochloride and dissolve it in deionized water, add 1.5g of antimony silica, ultrasonically disperse for 1 hour, and adjust the pH of the solution to 8.5 by adding tris(hydr...

Embodiment 3

[0043] Weigh 2 g of antimony trichloride and add it into deionized water, and stir at room temperature to form a clear solution A. In addition, 1.5 g of sodium borohydride and 7 g of sodium hydroxide were weighed and dissolved in deionized water to obtain solution B. Under the condition of stirring, at a temperature of 60° C., solution B was dropped into solution A drop by drop, and the stirring was continued for 1 h. Then centrifuge and wash to obtain nano-antimony particles; add 1g of nano-antimony particles prepared into 60mL of deionized water, 100mL of absolute ethanol and 3mL of 30wt.% ammonia water mixed solution, sonicate for 1h, measure 1g of ethyl orthosilicate dropwise Into it, stirred at 30°C for 3h. Centrifugal cleaning to obtain the core-shell structure of antimony silica; weigh 1g of dopamine hydrochloride and dissolve it in deionized water, add 1.5g of antimony silica, ultrasonically disperse for 2 hours, and adjust the pH of the solution to 8.5 by adding tris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com