A method for converting solar energy into electricity by electromagnetic induction

A solar energy conversion and electromagnetic induction technology, which is applied in the field of relative transportation, can solve the problems of liquid leakage of the phase change layer, certain difficulties in the connection of the phase change layer of the photoelectric conversion module and the thermoelectric conversion module, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

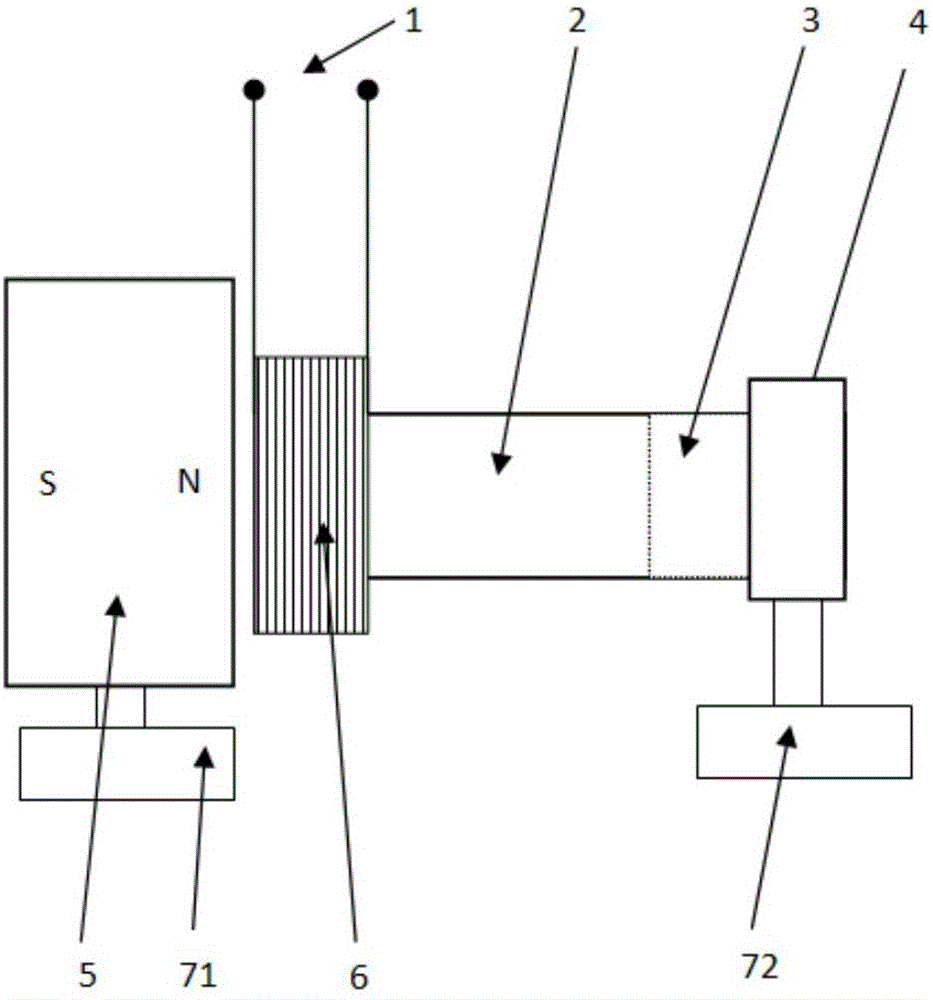

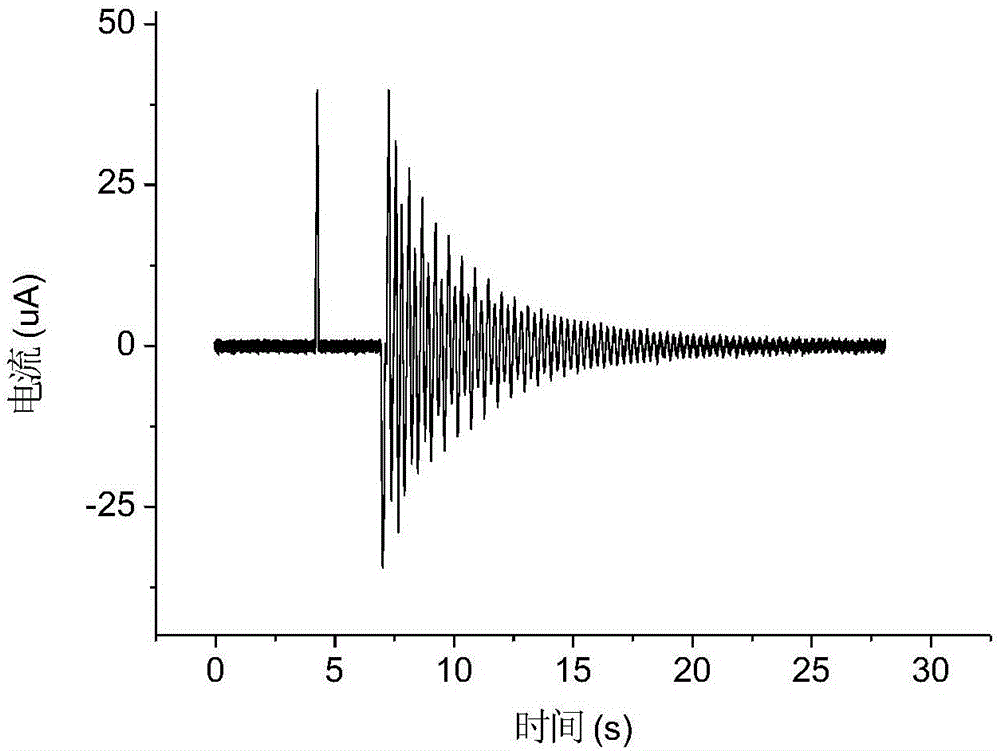

[0037] Example 1: see figure 1 , 2 , 3 and 4.

[0038] A method for converting solar energy into electric energy by electromagnetic induction, the steps are as follows:

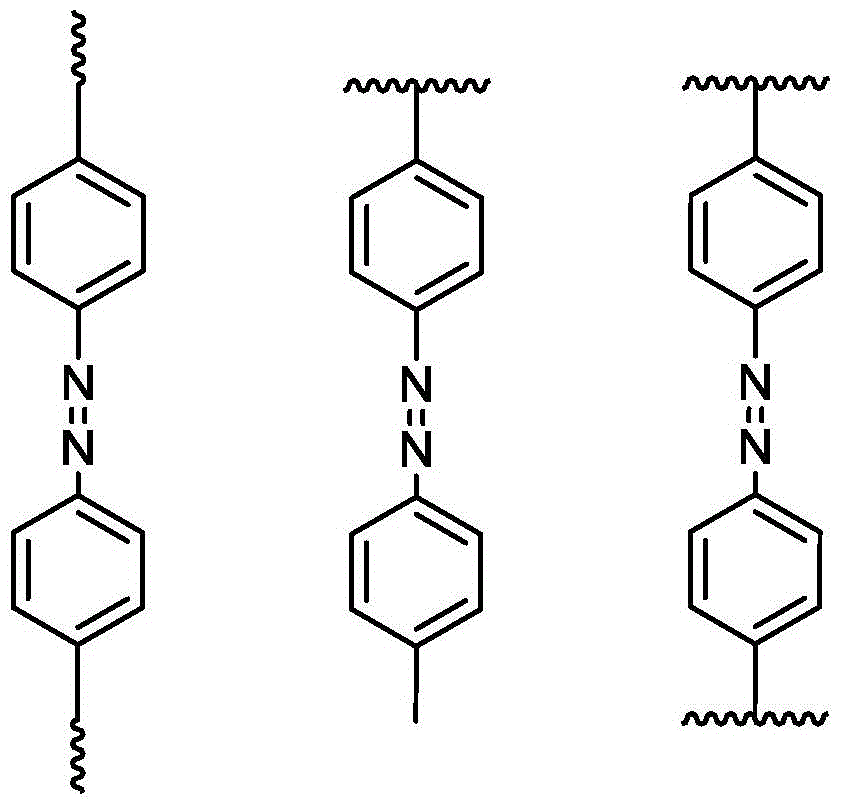

[0039] a, preparation of polymer double-layer composite film: use 1000 purpose sandpaper to polish along one direction on the surface of polyethylene (PE for short) film (ie polymer film) with a thickness of 20 μm, and form micro-grooves of micron level on the PE film, Then put the polished PE film in water, absolute ethanol, and acetone for 10 minutes for ultrasonic cleaning, put it in an oven at 40°C and blow dry for 24 hours, and then cast the photoactive polymer tetrahydrofuran solution on the PE film by solution casting method. A photoactive polymer film (or photoactive layer) (thickness 20 μm) is deposited on the top, and the tetrahydrofuran solution of the photoactive polymer adopts an anhydrous tetrahydrofuran solution of a photoactive polymer with a solution mass percent concentration of 10 wt%. A...

Embodiment 2

[0042] Example 2: see figure 1 , 2 and 5.

[0043] A method for converting solar energy into electric energy by electromagnetic induction, the steps are as follows:

[0044] a, preparation of polymer double-layer composite film: use 1000 purpose sandpaper to polish along one direction on the surface of polyethylene (PE for short) film (ie polymer film) with a thickness of 20 μm, and form micro-grooves of micron level on the PE film, Then put the polished PE film in water, absolute ethanol, and acetone for 10 minutes for ultrasonic cleaning, put it in an oven at 40°C and blow dry for 24 hours, and then cast the photoactive polymer tetrahydrofuran solution on the PE film by solution casting method. A photoactive polymer film (or photoactive layer) is deposited on it, and the tetrahydrofuran solution of the photoactive polymer adopts an anhydrous tetrahydrofuran solution with a solution mass percentage concentration of 10wt% photoactive polymer. After the tetrahydrofuran soluti...

Embodiment 3

[0047] Embodiment 3: see figure 1 , 2 and 6.

[0048] A method for converting solar energy into electric energy by electromagnetic induction, the steps are as follows:

[0049] a, preparation of polymer double-layer composite film: use 1000 purpose sandpaper to polish along one direction on the surface of polyethylene (PE for short) film (ie polymer film) with a thickness of 20 μm, and form micro-grooves of micron level on the PE film, Then put the polished PE film in clean water, absolute ethanol, and acetone for 10 minutes for ultrasonic cleaning, put it in an oven at 40°C and blow dry for 24 hours, and then cast the photoactive polymer tetrahydrofuran solution on the PE film by solution casting method. A photoactive polymer film (or photoactive layer) is deposited on it, and the tetrahydrofuran solution of the photoactive polymer adopts an anhydrous tetrahydrofuran solution with a solution mass percentage concentration of 10wt% photoactive polymer. After the tetrahydrofur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com