10-35kv insulating tubular bus and manufacturing method thereof

A technology of insulating tubes and busbars, which is applied in the direction of insulating cables, insulating conductors, and insulating conductors/cables. It can solve the problems of thermal expansion and contraction of insulating materials and conductive materials, cracking of insulating layers, damage of insulating layers, and high cost. The effects of increasing comprehensive competitiveness, small dielectric loss, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Preparation of three-layer co-extruded heat-shrinkable sleeve by irradiation crosslinking

[0043] Raw material composition: inner conductor shielding layer and outer insulating shielding layer: 100 parts by weight of polyethylene LDPE; 50 parts by weight of conductive functional filler high-structure carbon black; 1.5 parts by weight of antioxidant; lubricant (silicone and stearin Zinc acid) 4.5 parts by weight. Middle insulating layer: 10 parts by weight of rubber EPDM; 30 parts by weight of polyethylene LDPE; 10 parts by weight of thermoplastic elastomer EVA; 2 parts by weight of antioxidant; 1 part by weight of antioxidant; zinc fatty acid) 1.5 parts by weight;

[0044] Preparation of three-layer co-extruded heat-shrinkable sleeve:

[0045] A: Masterbatch preparation of the inner conductor shielding layer and the outer insulating shielding layer: the components of the inner conductor shielding layer and the outer insulating shielding layer are mixed acco...

Embodiment 2

[0050] Example 2: Preparation of three-layer co-extrusion heat-shrinkable sleeve by silane crosslinking method

[0051] Raw material composition: inner conductor shielding layer and outer insulating shielding layer: 100 parts by weight of polyethylene LDPE; 50 parts by weight of conductive functional filler high-structure carbon black; 1.5 parts by weight of antioxidant; lubricant (silicone and stearin Zinc acid) 4.5 parts by weight; silane crosslinking agent A171 2.0 parts by weight; initiator DCP 0.16 parts by weight; catalyst DBTDL 1.0 parts by weight. Middle insulating layer: 10 parts by weight of rubber EPDM; 30 parts by weight of polyethylene LDPE; 20 parts by weight of thermoplastic elastomer EVA; 2 parts by weight of antioxidant; 2 parts by weight of antioxidant; fatty acid zinc) 1.5 parts by weight; silane crosslinking agent A171 2.5 parts by weight; initiator DCP 0.18 parts by weight; catalyst DBTDL 0.65 parts by weight.

[0052] A: Masterbatch preparation of the in...

Embodiment 3 3

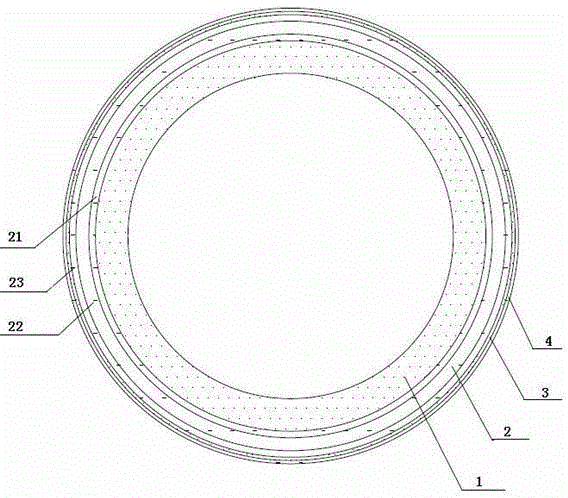

[0057] Example 3 Preparation of three-layer co-extrusion prefabricated 10-35kv insulated tubular busbar

[0058] A copper tube is selected as the metal tube conductor 1, with an outer diameter of 100 mm, a tube wall thickness of 8 mm, and a tube length of 6000 mm;

[0059] 1) Use a polishing tool to treat the burrs on the surface of the copper tube conductor 1, and use cleaning equipment to clean the copper tube conductor 1 to remove the dust on its surface, and finally use a clean towel dipped in acetone or alcohol to clean and wipe the surface;

[0060] 2) Shrink the three-layer co-extruded heat-shrinkable sleeve 2 prepared in Example 1 on the outer surface of the treated copper tube conductor 1;

[0061] 3) The outer surface of the three-layer co-extruded heat-shrinkable sleeve 2 is put into the full-length grounding screen 3;

[0062] 4) The outer surface of the metal grounding shielding layer is then covered with the outer sheath layer 4, which can effectively prevent th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com