A slag water waste heat heat exchange device for online backwashing

A technology for heat exchange devices and backwashing, which is applied in the direction of cleaning heat transfer devices, flushing, and heat exchange equipment. It can solve the problems of anti-blocking effect, unsatisfactory heat exchange efficiency, and inability to perform automatic backwashing to achieve efficient heat recovery. Energy saving, heat transfer effect and heat exchange efficiency enhancement, novel and unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

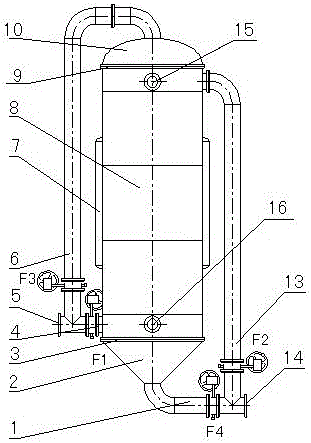

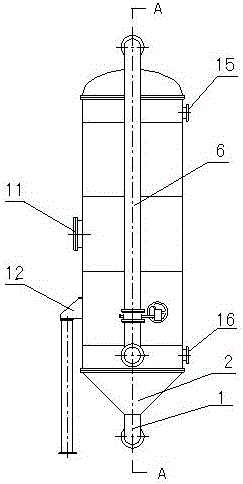

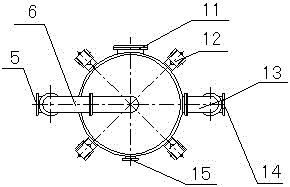

[0018] Depend on figure 1 — Figure 10 The slag water waste heat heat exchange device for online backwashing shown is a new type of heat exchange equipment that effectively utilizes the waste heat of blast furnace slag flushing water for heat exchange. Its middle part is the main body 8 of the slag water heat exchanger. Inside the main body of the heat exchanger 8 are two upper and lower four-channel spiral heat exchange cores, 17, 21, and the spiral heat exchange cores 17, 21 are connected through the semicircular diversion water boxes 7 on both sides of the shell. . Simultaneously communicate with circulating water inlet and outlet connecting pipes 16 and 15 respectively. The top of the main body 8 of the slag-water heat exchanger is connected to the elliptical head 10 through a detachable flange bolt combination 9; the bottom is connected to the conical head 2 through a detachable flange bolt combination 3; the outside is provided with a manhole for easy observation 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com