Spiral plate filter system and method

A filter system, spiral plate technology, applied in the field of filtration system, spiral plate filter system, spiral plate filter, can solve the problems of large filtration volume, low filtration efficiency, affecting the filtration flow area, etc., to increase the filtration area, Increase the pressure difference and improve the effect of filtration flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

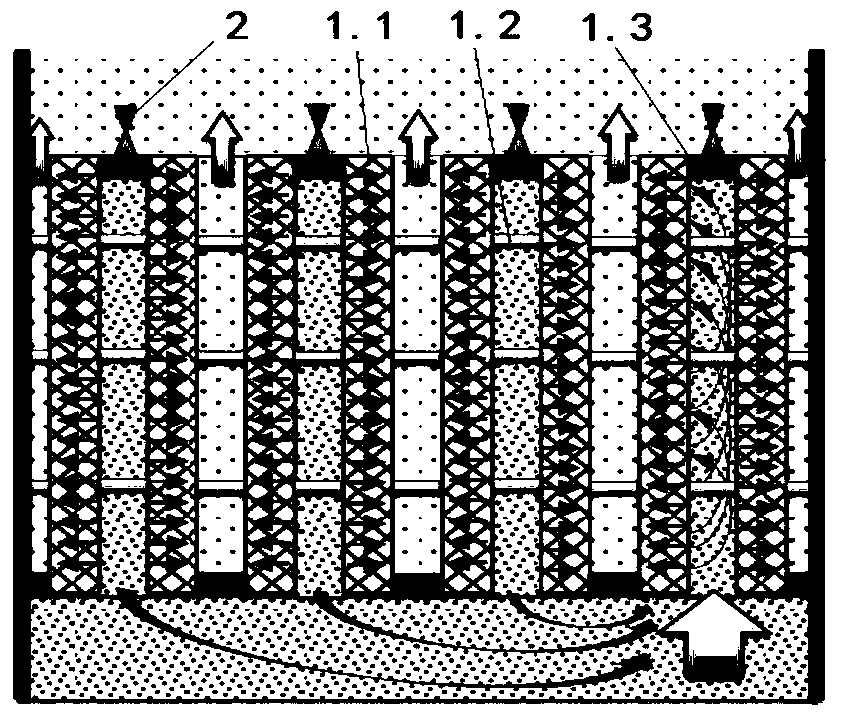

[0076] see figure 1 , the present invention discloses a structural schematic diagram of a spiral plate filter system, such as figure 1 : It includes a spiral plate filter element 1, a check valve 2, a filter housing 3, a controller 4, a water purification solenoid valve 5, an unfiltered water solenoid valve 6, a sewage solenoid valve 7, a backwash solenoid valve 8, and an air pump 9.

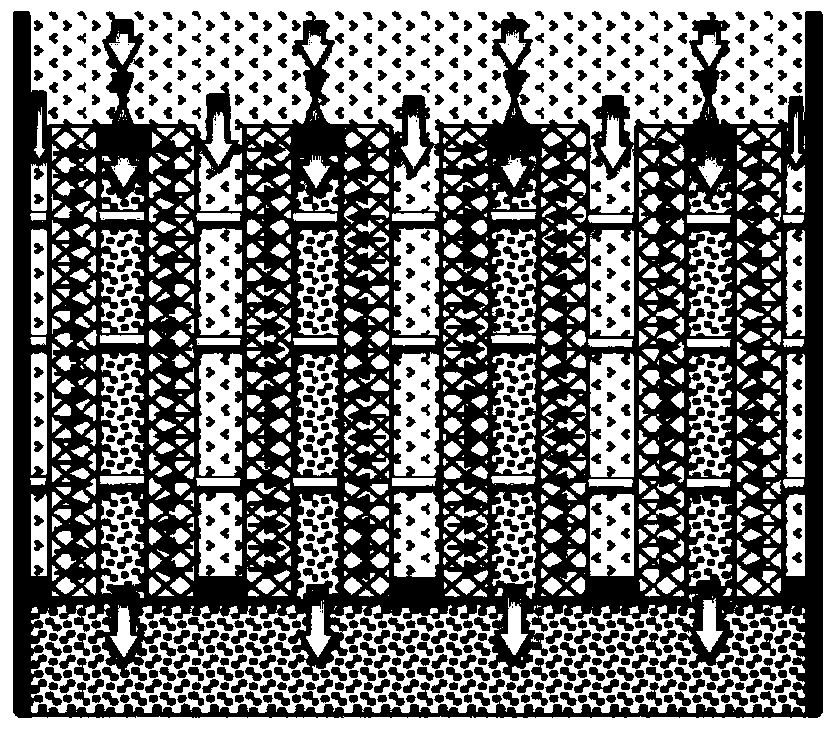

[0077] see figure 1 with figure 2 , the spiral plate filter element 1 is processed by rolling up two pieces of filter material 1.1, and a number of support columns 1.2 are embedded between the two pieces of filter material 1.1 to maintain the distance between the two pieces of filter material, and at the same time have a reinforcement The function of the filter core is that a sealing strip 1.3 is installed on the top of the filter core to prevent unfiltered water from entering the upper water purification area, and a sealing strip 1.3 is installed on the bottom of the filter core to prevent f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com