Two-degree-of-freedom motion decoupling flexible hinge mechanism

A technology of flexible hinges and degrees of freedom, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the difficulty of increasing the processing and assembly of mechanisms, and the decoupling performance is difficult to achieve Requirements, increase the quality of moving parts of the mechanism, etc., to achieve the effect of compact structure, large bending stiffness, and improved motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

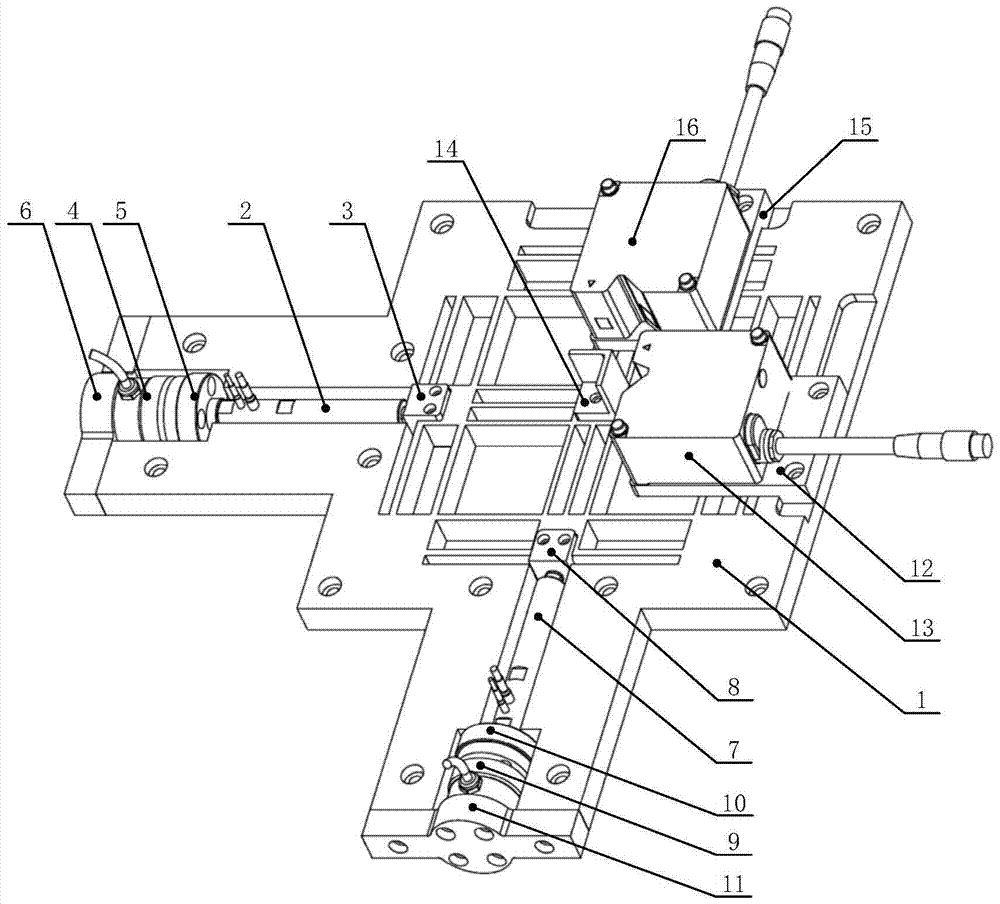

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] First, the component names in the reference numerals will be explained.

[0034] 1 flexible hinge base;

[0035] 2 a first piezoelectric ceramic actuator;

[0036] 3 first actuator connector;

[0037] 4. The first tension pressure sensor;

[0038] 5 the first flange;

[0039] 6 the first compression cover;

[0040] 7 the second piezoelectric ceramic actuator;

[0041] 8 second actuator connector;

[0042] 9 second tension pressure sensor;

[0043] 10 second flange;

[0044] 11 second compression cover;

[0045] 12 the first mount;

[0046] 13 the first laser displacement sensor;

[0047] 14 measuring base;

[0048] 15 second mount;

[0049] 16 second laser displacement sensor;

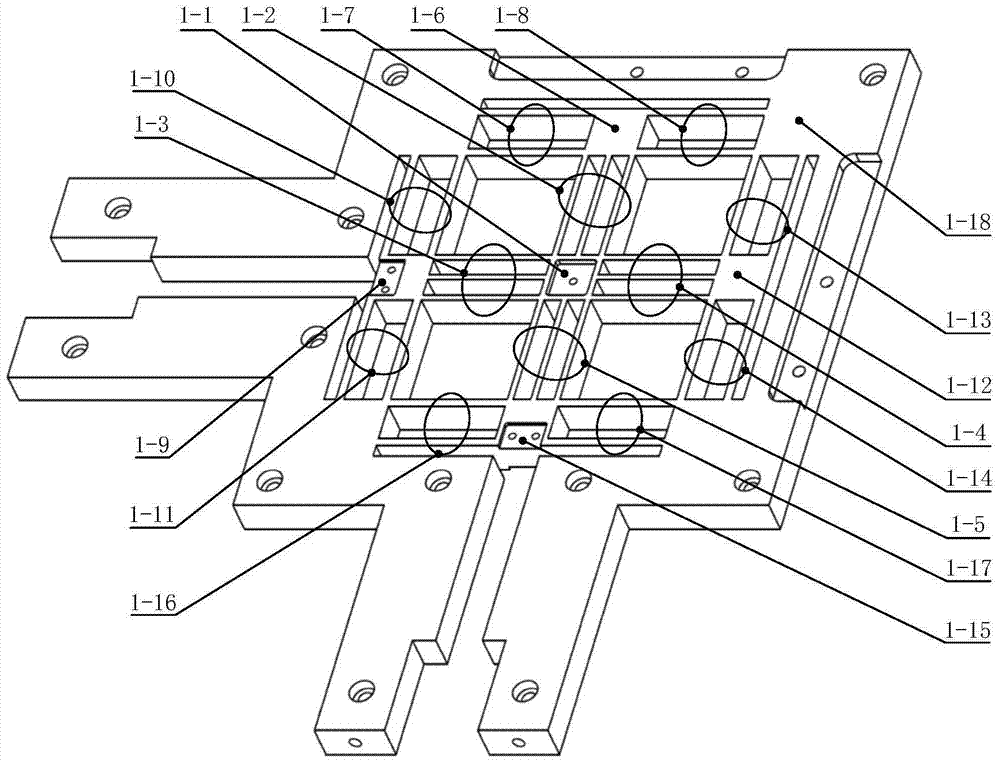

[0050] 1-1 terminal rigid output platform;

[0051] 1-2 flexible hinge branches;

[0052] 1-3 flexible hinge branches;

[0053] 1-4 flexible hinge branches;

[0054] 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com