Waste heat water toughening method and device for multi-mold assemblage casted high manganese steel casting

A treatment method, high manganese steel technology, applied in the fields of metal casting and heat treatment, to achieve the effect of improving production efficiency, reducing production cost, and reducing process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with embodiment.

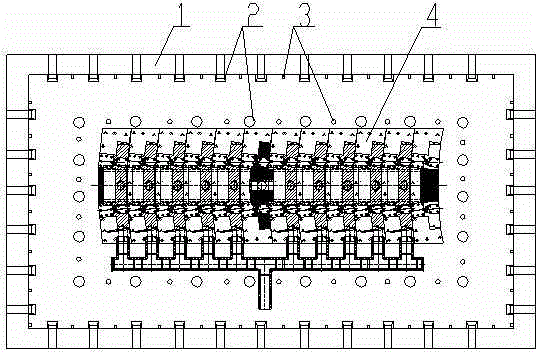

[0019] In order to illustrate the waste water toughening treatment method of the present invention, this example takes a 100 mm thick high manganese steel liner casting cast in series as an example to illustrate the practical application of the method of the present invention in detail. The series pouring process scheme of ten high manganese steel liner castings is as follows figure 1 shown.

[0020] The specific parameters of the high manganese steel liner casting are as follows:

[0021] Casting material: ZGMn13-4

[0022] Maximum dimensions of castings: 915mm×800mm

[0023] Casting wall thickness: 100mm

[0024] Casting blank weight: 570kg

[0025] The specific implementation steps of the technical scheme of waste heat and hot water toughening treatment of high manganese steel casting cast in series are as follows:

[0026] Step S101 When molten steel is smelted, the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com