Teflon high-temperature cloth impregnating emulsion glue tank

A technology of high temperature cloth and emulsion glue, applied in the direction of processing textile material containers, processing textile material equipment configuration, etc., can solve the problems of affecting use performance, temperature concentration, inconvenient replacement, maintenance, cleaning, etc., to achieve convenient cleaning and ensure performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following combination Attached picture and examples for further description.

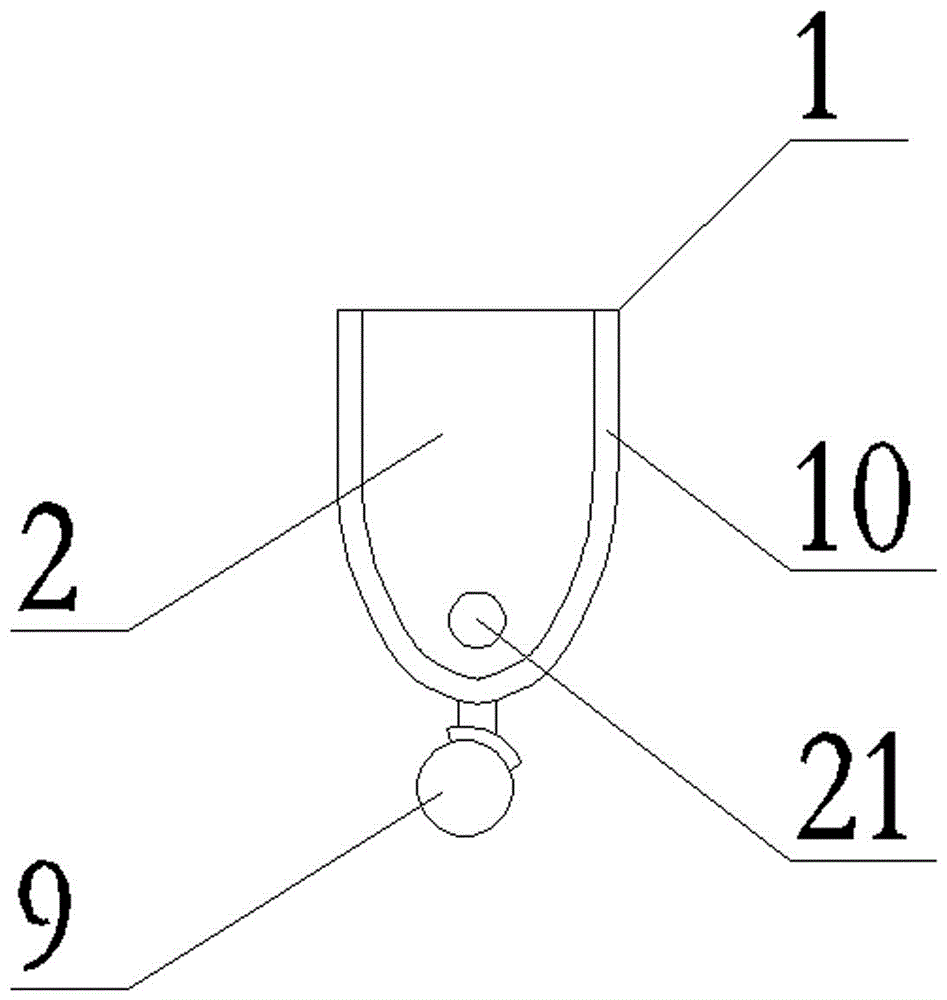

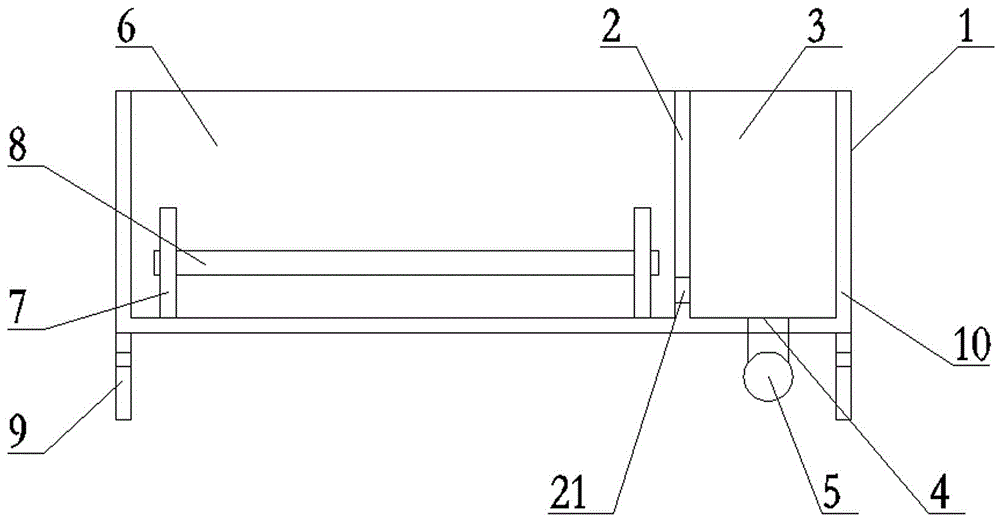

[0013] figure 1 Shown: a Teflon high-temperature cloth soaked latex rubber tank, including a tank body 1, the bottom of the tank body is arc-shaped, one side of the tank body is provided with a partition 2, and the partition board 2 divides the tank body into one part. It is a transfer feeding tank 3 on one side and an emulsion dipping tank 5 on the other side. The lower part of the partition 2 is provided with a through hole 21 connecting both sides, and the support 7 of the feeding roller 8 can be overhead in the emulsion dipping tank 6 , the bottom of the transfer feeding tank 3 is provided with a liquid outlet 4 with a valve 5, the tank wall of the tank body 1 is a hollow cavity 10, and the water in the hollow cavity is heated at a constant temperature to heat the inner emulsion. To the wheel 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com