Preparation method for biomass granular fuel

A biomass particle and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of reducing the performance and service life of combustion equipment, reducing combustion efficiency, and corrosion of combustion equipment, achieving excellent anti-slagging effect, improving Combustion efficiency, effect of increasing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

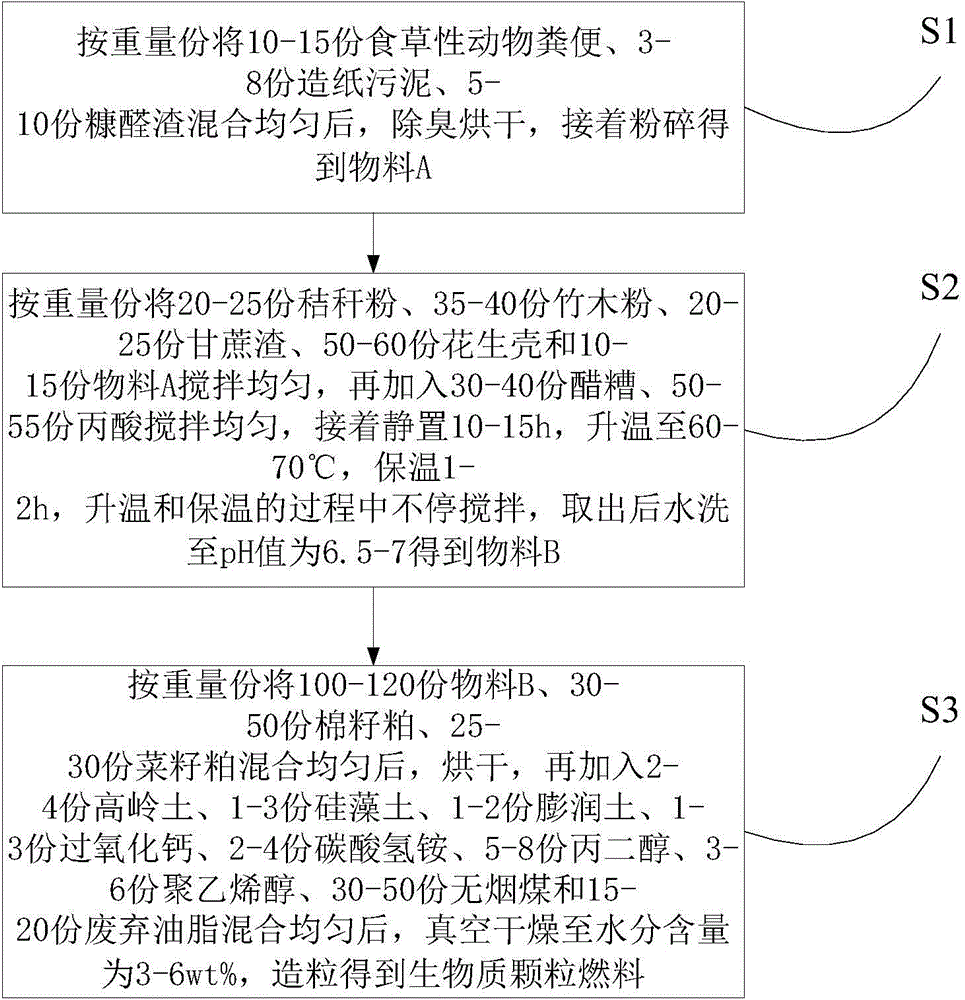

[0018] refer to figure 1 , the preparation method of a kind of biomass particle fuel that the present invention proposes, comprises the steps:

[0019] S1. After uniformly mixing 10-15 parts of herbivorous animal manure, 3-8 parts of papermaking sludge, and 5-10 parts of furfural slag in parts by weight, deodorize and dry, and then pulverize to obtain material A;

[0020] S2. Stir 20-25 parts of straw powder, 35-40 parts of bamboo and wood powder, 20-25 parts of bagasse, 50-60 parts of peanut shells and 10-15 parts of material A in parts by weight, and then add 30-40 parts Stir the vinegar grains and 50-55 parts of propionic acid evenly, then let it stand for 10-15 hours, raise the temperature to 60-70°C, keep it warm for 1-2 hours, keep stirring during the heating and heat preservation process, take it out and wash it with water until the pH value is 6.5- 7 get material B;

[0021] S3. Mix 100-120 parts of material B, 30-50 parts of cottonseed meal, and 25-30 parts of rapes...

Embodiment 1

[0024] A kind of preparation method of biomass particle fuel that the present invention proposes, comprises the steps:

[0025] S1. Mix 10 parts of herbivorous animal feces, 8 parts of papermaking sludge, and 5 parts of furfural slag uniformly by weight, deodorize and dry, and then pulverize to obtain material A;

[0026] S2. Stir 25 parts of straw powder, 35 parts of bamboo wood powder, 25 parts of bagasse, 50 parts of peanut shells and 15 parts of material A in parts by weight, then add 30 parts of vinegar grains and 55 parts of propionic acid and stir evenly, then static Put it in place for 10 hours, raise the temperature to 70°C, keep it warm for 1 hour, keep stirring during the heating and heat preservation process, take it out and wash it with water until the pH value is 6.5-7 to obtain material B;

[0027] S3. Mix 120 parts of material B, 30 parts of cottonseed meal, and 30 parts of rapeseed meal in parts by weight, dry, then add 2 parts of kaolin, 3 parts of diatomaceo...

Embodiment 2

[0029] A kind of preparation method of biomass particle fuel that the present invention proposes, comprises the steps:

[0030] S1. After uniformly mixing 15 parts of herbivorous animal excrement, 3 parts of papermaking sludge and 10 parts of furfural slag in parts by weight, deodorize and dry, and then pulverize to obtain material A;

[0031] S2. Stir 20 parts of straw powder, 40 parts of bamboo wood powder, 20 parts of bagasse, 60 parts of peanut shells and 10 parts of material A in parts by weight, then add 40 parts of vinegar grains and 50 parts of propionic acid and stir evenly, then static Put it in place for 15 hours, raise the temperature to 60°C, keep it warm for 2 hours, keep stirring during the heating and heat preservation process, take it out and wash it with water until the pH value is 6.5-7 to obtain material B;

[0032] S3. Mix 100 parts of material B, 50 parts of cottonseed meal, and 25 parts of rapeseed meal in parts by weight, dry, and then add 4 parts of ka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com