Low-high temperature combined normal-pressure powder coal gasification furnace and gasification technological method

A low-temperature gasification and gasifier technology, applied in the field of coal gasification, can solve the problems of high carbon content, low carbon utilization rate, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

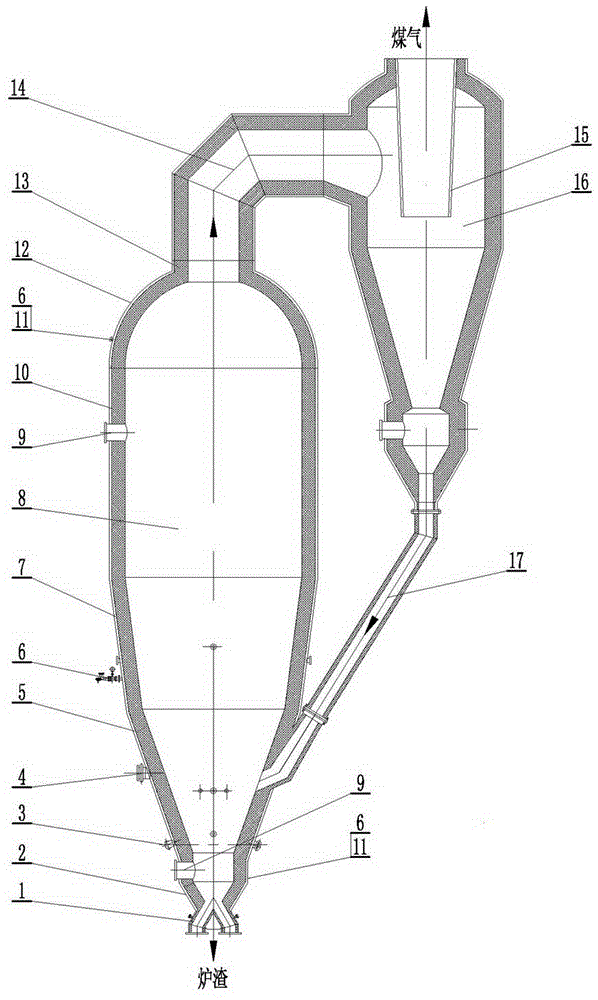

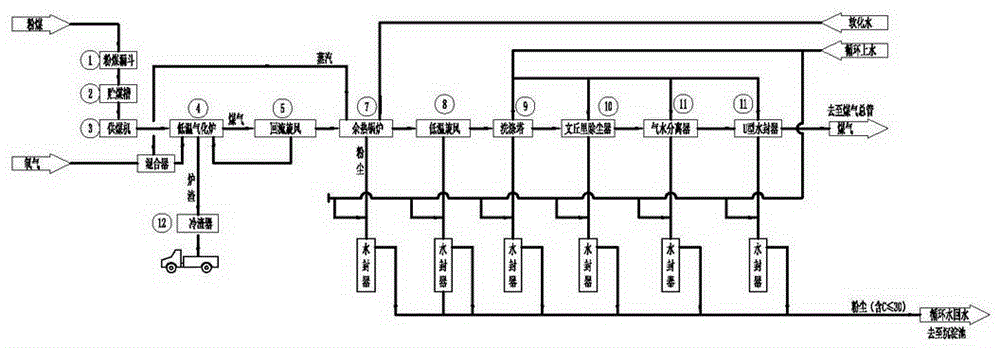

[0039] The existing atmospheric pulverized coal gasification furnace is mainly composed of a generator 8, a high-temperature return cyclone separator 16, a gas pipe 14, and a return pipe 17. The generator 8 has a cylindrical furnace body 10 and a cone 7 in the middle, and the top is arched. The head 12, the bottom is a conical head 5, the furnace body and the top head are lined with insulation bricks and refractory bricks, the middle cone 7 and the conical head 5 are lined with a heat-resistant layer.

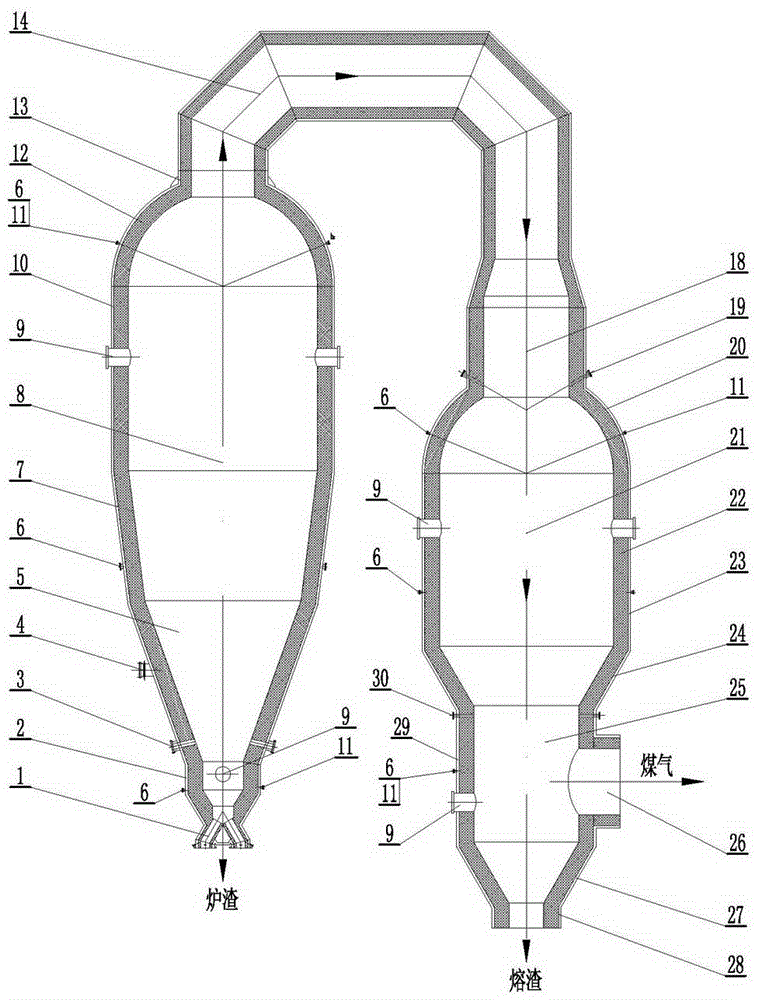

[0040] The low-temperature combined atmospheric pressure pulverized coal gasifier of the present invention is mainly composed of a low-temperature gasifier 8 , a gas pipe 14 and a high-temperature reaction furnace 21 .

[0041] The low-temperature gasification furnace 8 is basically the same as the prior art, except that the cone angle of the middle cone 7 is 12-18°, and the inclination angle of the bottom cone head 5 is 30-40°. The low-temperature gasification furnace 8 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com