A system for improving the recovery rate of liquefied natural gas

A liquefied natural gas, recovery rate technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of reducing methane recovery rate, increasing energy consumption per unit of liquefied natural gas production, and reducing energy consumption of liquefied natural gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

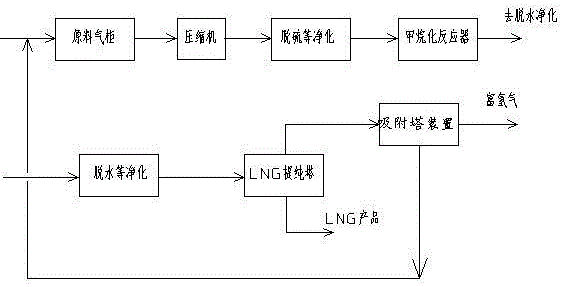

[0031] A system for improving the recovery rate of liquefied natural gas, including feed gas delivery pipes, compressors, methanation reactors, liquefied natural gas purification towers, pipelines and pressure swing adsorption devices, the pressure swing adsorption device is equipped with a pressure swing adsorption tower, feed gas delivery The pipe is connected to the compressor, the compressor is connected to the methanation reactor, the methanation reactor is connected to the LNG purification tower, the LNG purification tower is connected to the PSA tower, and the PSA tower is connected to the LNG purification tower. The connection between the devices is connected by corresponding pipelines; during the production of liquefied natural gas, the raw gas passes through the raw gas delivery pipe, the compressor and the methanation reactor in turn, and then enters the liquefied natural gas purification tower for reaction, and the non-condensable gas released from the liquefied natu...

Embodiment 2

[0034] A system for improving the recovery rate of liquefied natural gas, including feed gas delivery pipes, compressors, methanation reactors, liquefied natural gas purification towers, pipelines and pressure swing adsorption devices, the pressure swing adsorption device is equipped with a pressure swing adsorption tower, feed gas delivery The pipe is connected to the compressor, the compressor is connected to the methanation reactor, the methanation reactor is connected to the liquefied natural gas purification tower, the liquefied natural gas purification tower is connected to the pressure swing adsorption tower, and the above devices are connected through corresponding pipelines; During the production of liquefied natural gas, the raw gas passes through the raw gas delivery pipe, compressor and methanation reactor in turn, and then enters the liquefied natural gas purification tower. The non-condensable gas discharged from the liquefied natural gas purification tower passes ...

Embodiment 3

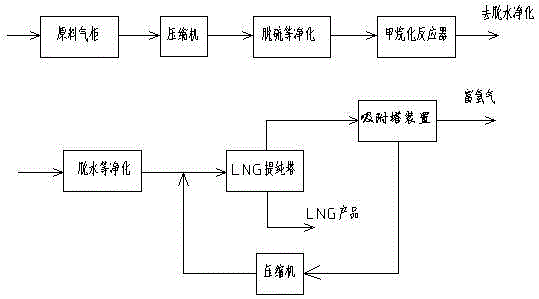

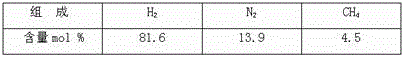

[0036]A system for increasing the recovery rate of liquefied natural gas, comprising raw gas delivery pipes, raw gas cabinets, desulfurization purification towers, compressors, methanation reactors, dehydration and impurity purifiers, liquefied natural gas purification towers, pipelines and pressure swing adsorption devices, The pressure swing adsorption device is equipped with a pressure swing adsorption tower, the feed gas delivery pipe is connected to the feed gas cabinet, the feed gas cabinet is connected to the compressor, the compressor is connected to the desulfurization purification tower, the desulfurization purification tower is connected to the methanation reactor, and the methanation reaction The dehydration and impurity purifier is connected with the dehydration and impurity purifier, the dehydration and impurity purifier is connected with the liquefied natural gas purification tower, the liquefied natural gas purification tower is connected with the adsorption towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com