Method for producing hydrogen by alkalescent microbe electrolysis

A microbial electrolysis and microbial technology, applied in the direction of electrolysis process, electrolysis components, chemical instruments and methods, etc., can solve the problems of hydrogen production efficiency reduction, achieve the effect of improving utilization rate, suppressing methane production, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

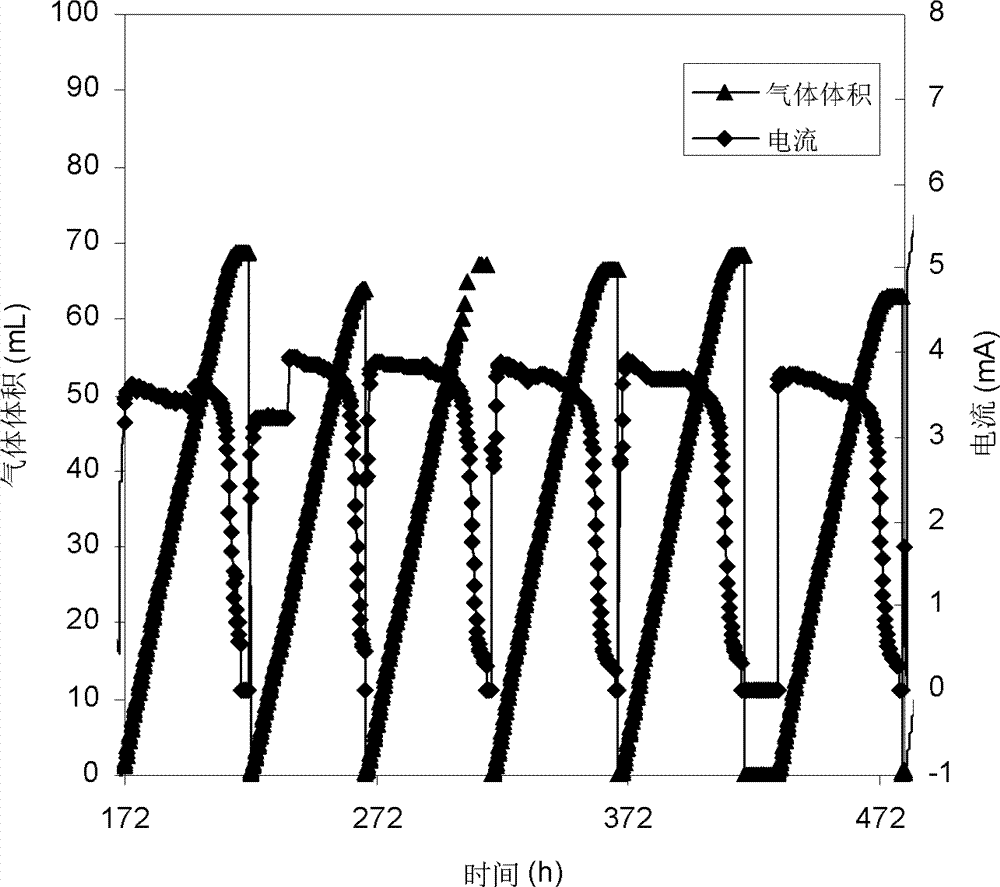

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below through specific embodiments.

[0026] Alkaline microbial electrolytic cell hydrogen production method among the present invention, comprises steps:

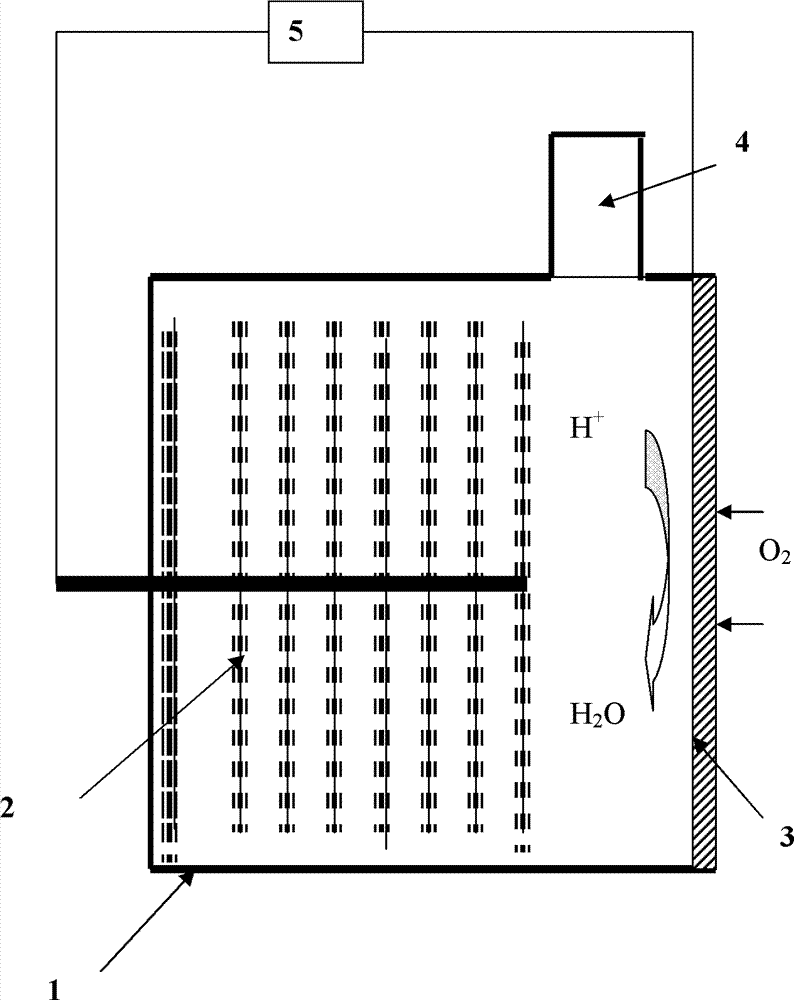

[0027] (1) Start the electrolytic cell in microbial fuel cell mode:

[0028] First, uniformly mix the organic waste water and the nutrient solution A at a volume ratio of 1:1, then adjust the pH of the mixed solution to 9-12 with an alkaline solution, and add an organic substrate at a ratio of 1 g / liter to obtain a mixed solution B; Add the mixed solution B into the electrolytic cell, and connect a 1000 ohm resistor in the closed circuit of the system. When the voltage across the resistor is lower than 20mV, replace the solution in the electrolytic cell with the new mixed solution B; continue to replace the reactor solution until When the voltage across the resistor is greater than 500mV, the anode start is complete;

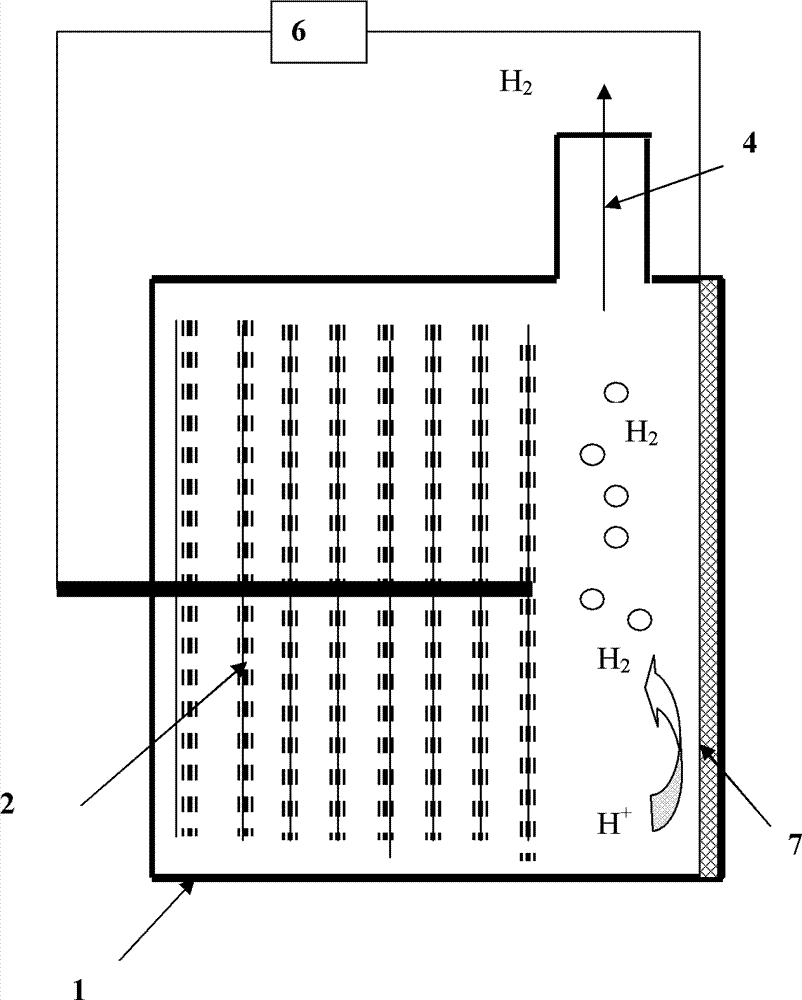

[0029] (2) Hydrogen prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com