SPEEK (sulfonated poly (ether ether ketone)) proton exchange membrane material with epoxy resin interpenetrating polymer network and preparation method of SPEEK proton exchange membrane material

A technology for sulfonated polyether ether ketone and proton exchange membrane, which is applied in the field of epoxy resin semi-interpenetrating network sulfonated polyether ether ketone proton exchange membrane material and its preparation field, and can solve the problem of high proton conductivity, low power density, Shortened battery life and other problems, to achieve the effect of low preparation cost, good alcohol resistance and moderate conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

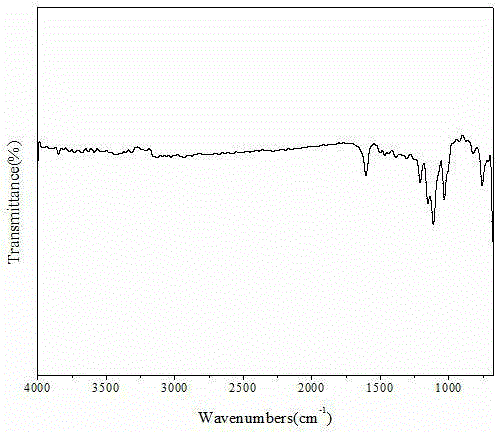

Image

Examples

Embodiment 1

[0023] (1) Dissolve (1.7000g, 0.0050mol) of SPEEK (sulfonation degree 75) in 30mL of DMAc solvent in a 100mL three-necked flask equipped with magnetic rotor stirring, condenser, and thermometer, turn on the magnetic stirring, oil Heating the heating bath to 60°C to prepare a membrane-forming solution;

[0024] (2) Dissolve (0.39848g, 0.001mol) epoxy resin in DMAc solvent, ultrasonically disperse for 4-6 hours, add (0.04656ml) diethylenetriamine, inert atmosphere protection, stir at room temperature for 15-20 hours, 120 Mechanically stir the reaction at ~160°C for 0.5-1 hour.

[0025] (3) Pour the film-making solution obtained in step (2) into the glass mold cavity before cooling, dry at 50-60°C for 10-15 hours, then rise to 100°C and dry for 4-6 hours, remove the solvent, and wait After it is naturally cooled to room temperature, the film is peeled off to obtain an epoxy resin semi-interpenetrating network sulfonated polyether ether ketone proton exchange membrane material. ...

Embodiment 2

[0049] (1) Dissolve (3.4000g, 0.0100mol) of SPEEK (sulfonation degree 75) in 30mL of DMAc solvent in a 100mL three-neck flask equipped with magnetic rotor stirring, condenser, and thermometer, turn on the magnetic stirring, and the oil Heating the heating bath to 100°C to prepare a membrane-forming solution;

[0050] (2) Dissolve (0.39848g, 0.001mol) epoxy resin in DMAc solvent, ultrasonically disperse for 4-6 hours, add (0.04656ml) diethylenetriamine, inert atmosphere protection, stir at room temperature for 15-20 hours, 120 Mechanically stir the reaction at ~160°C for 0.5-1 hour.

[0051] (3) Pour the film-making solution obtained in step (3) into the glass mold cavity before cooling, dry at 50-60°C for 10-15 hours, then rise to 100°C and dry for 4-6 hours, remove the solvent, and wait After it is naturally cooled to room temperature, the membrane is peeled off to obtain a semi-interpenetrating network p-aminobenzenesulfonic acid graphene oxide doped sulfonated polyether et...

Embodiment 3

[0060] (1) Dissolve (2.0400g, 0.0060mol) of SPEEK (sulfonation degree 75) in 30mL of DMAc solvent in a 100mL three-neck flask equipped with magnetic rotor stirring, condenser, and thermometer, turn on the magnetic stirring, and the oil Heating the heating bath to 100°C to prepare a membrane-forming solution;

[0061] (2) Dissolve (0.79696g, 0.002mol) epoxy resin in DMAc solvent, ultrasonically disperse for 4-6 hours, add (0.04656ml) diethylenetriamine, inert atmosphere protection, stir at room temperature for 15-20 hours, 120 Mechanically stir the reaction at ~160°C for 0.5-1 hour.

[0062] (3) Pour the film-making solution obtained in step (2) into the glass mold cavity before cooling, dry at 50-60°C for 10-15 hours, then rise to 100°C and dry for 4-6 hours, remove the solvent, and wait After it is naturally cooled to room temperature, the film is peeled off to obtain an epoxy resin semi-interpenetrating network sulfonated polyether ether ketone proton exchange membrane mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com