Rubber vulcanized rubber containing ionic liquid modified graphene oxide and preparation method of vulcanized rubber

A technology of ionic liquid and oxide stone, which is applied in the field of ionic liquid modified graphene oxide/rubber vulcanizate and its preparation, can solve the problems of limited varieties, cumbersome modification steps of silane coupling agent, etc., and achieve excellent mechanics and preparation steps Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of the multifunctional rubber vulcanizate containing modified graphene oxide of the present invention comprises the following steps:

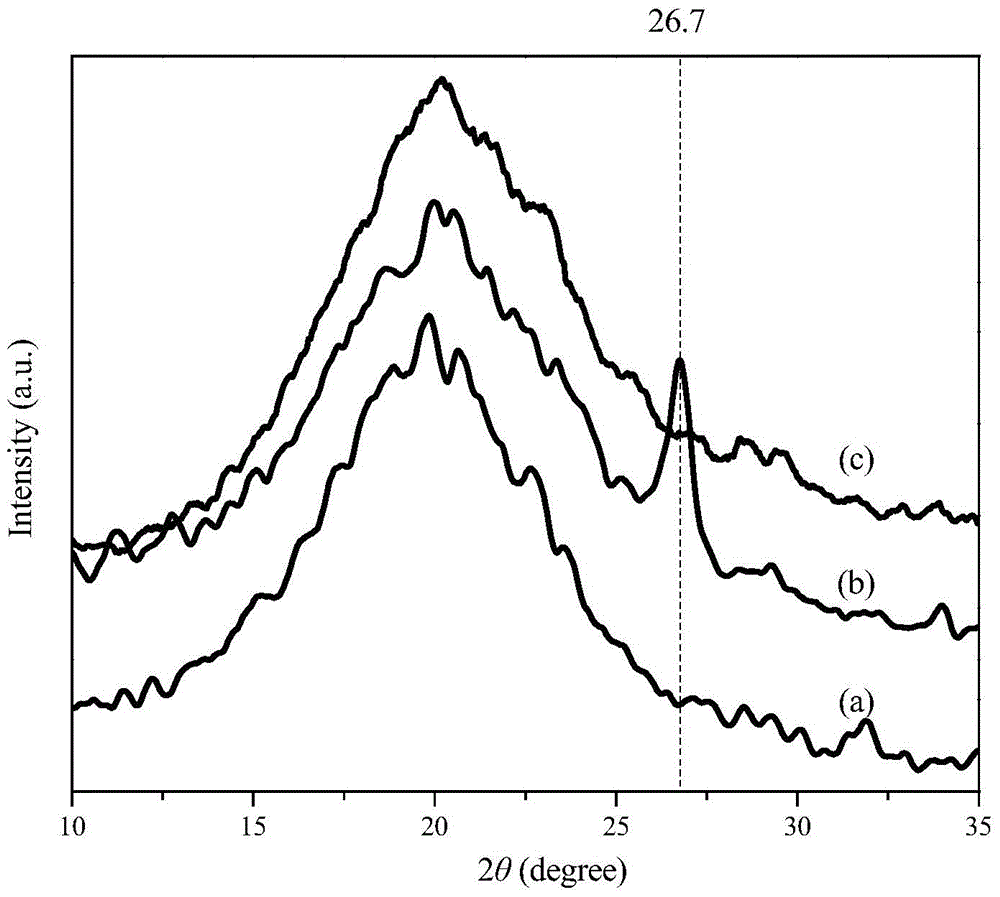

[0028] Step 1: Preparation of ionic liquid modified graphene oxide: add graphite oxide into aqueous solution, ultrasonically disperse, ultrasonic time 0.5-1h, power 100-300W, add ionic liquid, continue ultrasonic treatment, ultrasonic time 0.5-1h , power 100-300W, to obtain ionic liquid modified graphene oxide;

[0029] Step 2: mixing and stirring the ionic liquid modified graphene oxide prepared in step 1 with rubber latex, adding a gelling agent, washing and drying the gel to obtain a rubber mixture containing ionic liquid modified graphene oxide;

[0030] Step 3: After mixing the rubber mixture containing ionic liquid modified graphene oxide obtained in step 2 with zinc oxide, stearic acid, anti-aging agent, vulcanization accelerator and vulcanizing agent on the open mill, park it, and use vulcanization T...

Embodiment 1

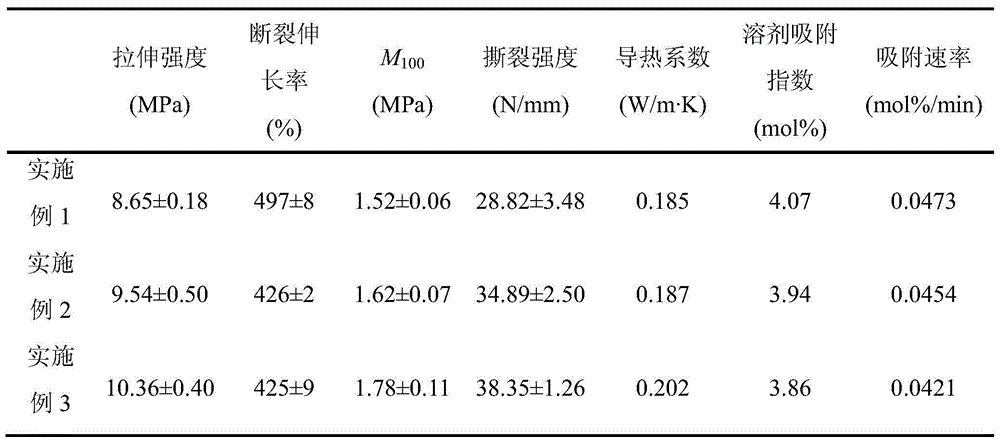

[0042]Add 2 parts of graphite oxide into the aqueous solution, ultrasonically disperse, ultrasonic time 1h, power 100W, then add 2 parts of ionic liquid, continue ultrasonic treatment, ultrasonic time 1h, power 100W, to obtain ionic liquid modified graphene oxide; It is mixed and stirred with styrene-butadiene rubber latex, and a gelling agent is added, and the gel is washed and dried to obtain a modified graphene oxide / styrene-butadiene rubber mixture; 2 parts of zinc oxide, 1 part of stearic acid , 2 parts of anti-aging agent RD, 1 part of vulcanization accelerator DM, 4 parts of sulfur, and the formula containing 2 parts of modified graphene oxide was mixed evenly. After the mixed rubber was parked for 24 hours, the corresponding positive vulcanization time was measured, and then pressed with a flat vulcanizer to obtain a modified graphene oxide / styrene-butadiene rubber vulcanizate containing 2 parts of ionic liquid. The tensile strength of the obtained vulcanizate was 8.65...

Embodiment 2

[0044] Repeat the method of Example 1 according to the specified content of each component, but adopt 3 parts of modified graphene oxide in the formula, the tensile strength of the vulcanized rubber is 9.54MPa, and the modulus when the strain is 100% is 1.62MPa , elongation at break 426%, tear strength 34.89N / mm, thermal conductivity 0.187W / m·K. The adsorption index for toluene is 3.94mol%, and the adsorption rate is 0.0454mol% / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com