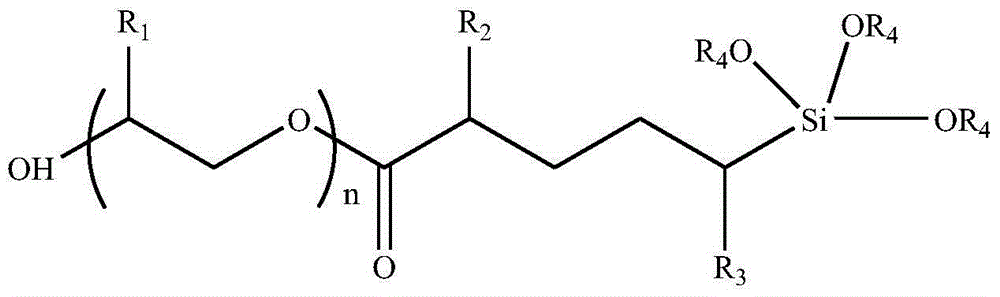

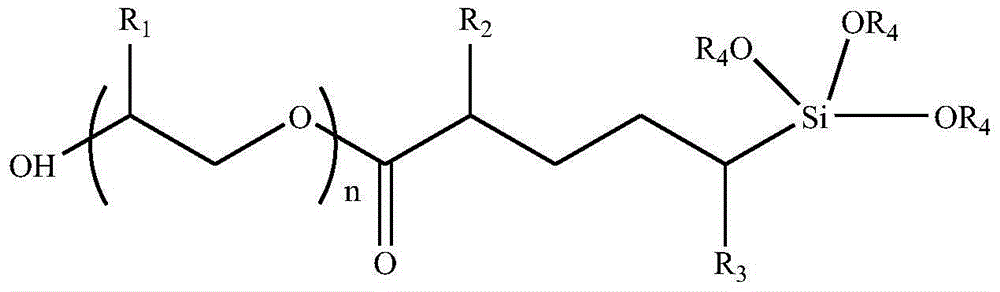

Preparation method of long chain terminal hydroxyl-containing silane coupling agent and application thereof

A chain-terminated hydroxysilane coupling agent and technology of silane coupling agent are applied in the field of synthesis and application research of organosilicon functional compound intermediates, which can solve the problem of small shear force of water flow, removal of fouling organisms, and difficulty in exerting antifouling effect. and other problems, to achieve the effect of easy reaction process and solving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: in the there-necked flask of 500ml that stirrer, condenser, thermometer are housed, add the mixed solvent of 120g xylene / n-butanol (the mass ratio of xylene and n-butanol is 1:1), and add 25g of polyethylene glycol acrylate and 30g of γ-(methacryloyloxy)propyltrimethoxysilane, blow nitrogen into the reaction system, and stir to mix the reaction monomers evenly, raise the temperature to 115°C, and react within 2 hours After adding 2g of tert-butyl peroxy-2-ethylhexanoate dropwise to the system, keep the temperature for 0.5h, and continue to add 0.5g of tert-butyl peroxy-2-ethylhexanoate and 10g of xylene / Mixed solvent of n-butanol (mass ratio of xylene to n-butanol is 1:1), keep warm for 0.5h, cool down and discharge to obtain the crude product, carry out vacuum distillation on the crude product to remove the low boiling point fraction, obtain colorless and transparent liquid product.

Embodiment 2

[0016] Embodiment 2: in the there-necked flask of 500ml that stirrer, condenser, thermometer are housed, add the mixed solvent of 110g toluene / n-butanol (the mass ratio of toluene and n-butanol is 1:1), and add 28g poly Ethylene glycol methacrylate and 30g γ-(methacryloyloxy)propyltrimethoxysilane, blow nitrogen into the reaction system, and stir to mix the reaction monomers evenly, raise the temperature to 110°C, and react within 2h Add 2g of tert-butyl peroxy-2-ethylhexanoate dropwise to the system, keep the temperature for 0.5h, and continue to add 0.5g of tert-butyl peroxy-2-ethylhexanoate and 10g of toluene / normal Mixed solvent of butanol (mass ratio of toluene to n-butanol is 1:1), keep warm for 0.5h, cool down and discharge the material to obtain the crude product, carry out vacuum distillation on the crude product to remove the low boiling point fraction, and obtain a colorless transparent liquid product .

Embodiment 3

[0017] Embodiment 3: in the there-necked flask of 500ml that stirrer, condenser, thermometer are housed, add the mixed solvent of 120g xylene / n-butanol (the mass ratio of xylene and n-butanol is 1:1), and add 20g of polyethylene glycol acrylate and 25g of vinyl tris(β-methoxyethoxy)silane, pass nitrogen gas into the reaction system, and stir to make the reaction monomers mix evenly, heat up to 115°C, and react within 2h Add 1.8g of tert-butyl peroxy-2-ethylhexanoate dropwise to the system, keep it warm for 0.5h, continue to add 0.5g of tert-butyl peroxy-2-ethylhexanoate and 8g of xylene dropwise within 0.5h / n-butanol mixed solvent (the mass ratio of xylene to n-butanol is 1:1), heat preservation for 0.5h, cool down and discharge, obtain the crude product, carry out vacuum distillation on the crude product to remove the low boiling point fraction, obtain light yellow Clear liquid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com