A kind of preparation method of zno double flower head structure and the product obtained therefrom

A flower-like structure and flower head technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of poor size control effect, poor morphology uniformity, poor repeatability, etc., and achieve low price of raw materials, special morphology, and good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.1 Add 0.439 g of zinc acetate to a mixed solvent of 30 mL of ethylene glycol and 1.5 mL of water and stir until clear;

[0033] 1.2 Add 3 mL of ethanolamine dropwise to the above solution and stir evenly;

[0034] 1.3 Transfer the above solution to the reactor and react at 150 °C for 12 h;

[0035] 1.4 After the reaction, the product was obtained after centrifugation and washing.

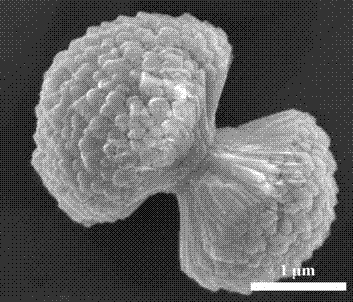

[0036] SEM of the product as figure 1 As shown, it can be seen from the figure that the obtained product is a double flower head structure formed by closely arranged ZnO rods. The two flower heads are connected at the bottom, similar in size, and on the same horizontal line. The diameter of each flower head is 2.1-2.5 μm , with a length of 0.8-1.6 μm; the structural unit ZnO rods have a diameter of 0.15-0.22 μm and a length of 0.8-1.6 μm.

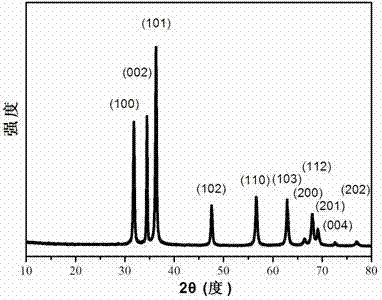

[0037] The XRD pattern of the product is as follows figure 2 As shown, the XRD results are consistent with the standard XRD card (36-1451), which p...

Embodiment 2

[0040] 2.1 Add 0.535 g of zinc nitrate hexahydrate to a mixed solvent of 30 mL of ethylene glycol and 1.5 mL of water and stir until clear;

[0041] 2.2 Add 2.7 mL of ethanolamine dropwise to the above solution and stir evenly;

[0042] 2.3 Transfer the above solution to the reactor and react at 130 °C for 2 h;

[0043] 2.4 After the reaction, after centrifugation and washing, the obtained product is a double flower head structure formed by closely arranged ZnO rods, in which the bottoms of the two divergent flower heads are connected, similar in size, and on the same horizontal line. The diameter is 0.12-0.16 μm, and the length is 0.07-0.14 μm; the diameter of its structural unit ZnO rod is 0.06-0.12 μm, and the length is 0.07-0.14 μm.

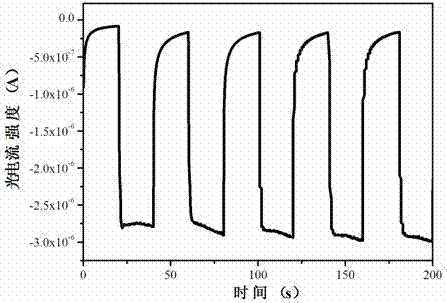

[0044] The product is irradiated by a 365 nm ultraviolet lamp, and the illuminated area is 1.5cm 2 Under the condition, its photocurrent intensity can reach -1.50×10 -6 a.

Embodiment 3

[0046] 3.1 Add 0.850 g of zinc nitrate hexahydrate to a mixed solvent of 30 mL of ethylene glycol and 1.6 mL of water and stir until clear;

[0047] 3.2 Add 4.5 mL of ethanolamine dropwise to the above solution and stir evenly;

[0048] 3.3 Transfer the above solution to the reactor and react at 170 °C for 27 h;

[0049] 3.4 After the reaction, after centrifugation and washing, the obtained product is a double flower head structure formed by closely arranged ZnO rods, in which two divergent flower heads are connected at the bottom, similar in size, and on the same horizontal line. The diameter of each flower head is 7.2-7.6 μm, the length is 3.0-5.6 μm; the diameter of its structural unit ZnO rod is 0.38-0.45 μm, and the length is 3.0-5.6 μm.

[0050] The product is irradiated by a 365 nm ultraviolet lamp, and the illuminated area is 1.5cm 2 Under the condition, its photocurrent intensity can reach -1.72×10 -6 a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com