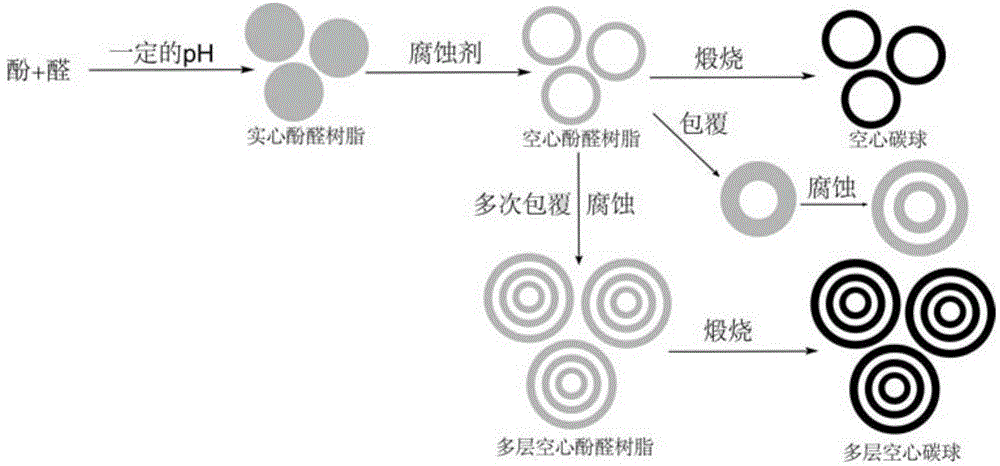

Single-layer and multi-layer hollow carbon nanospheres, and preparation and application thereof

A hollow carbon sphere, single-layer technology, applied in the fields of nanotechnology, nanotechnology, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of cumbersome steps in the template method, and achieve the effect of mild reaction conditions and simple operation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

[0094] Embodiment A1, using method A to prepare hollow carbon spheres:

[0095] 1) Weigh 0.1g 3-aminophenol (0.92mmol) and dissolve it in 30ml H 2 O to obtain a 3-aminophenol aqueous solution with a mass concentration of 3.3 mg / ml. Then add 0.1ml mass percent concentration of 25% ammonia (1.30mmol) and 0.1ml mass concentration of 37% formaldehyde solution (1.34mmol), stir at room temperature for 1.5h, this time 3-aminophenol formaldehyde can be obtained Solid spheres of resin polymers, such as figure 2 shown. Add 20ml of acetone to the reaction vessel, continue stirring at room temperature for 30min, centrifuge the precipitate, and wash it twice with ethanol, and place the obtained precipitate in a drying oven at 80°C for 4 hours to obtain a single layer of 3-aminophenol formaldehyde resin. Hollow spheres of ester polymers, i.e. intermediate I, such as image 3 shown;

[0096] 2) The dried intermediate product I was placed in a tube furnace with a hydrogen-argon gas mixt...

Embodiment A2

[0098] Embodiment A2, using method A to prepare hollow carbon spheres:

[0099] The difference with embodiment A1 is:

[0100] Weigh 0.12g resorcinol (1.09mmol) and dissolve in 20ml H 2 O, to obtain a mass concentration of resorcinol aqueous solution of 6mg / ml.

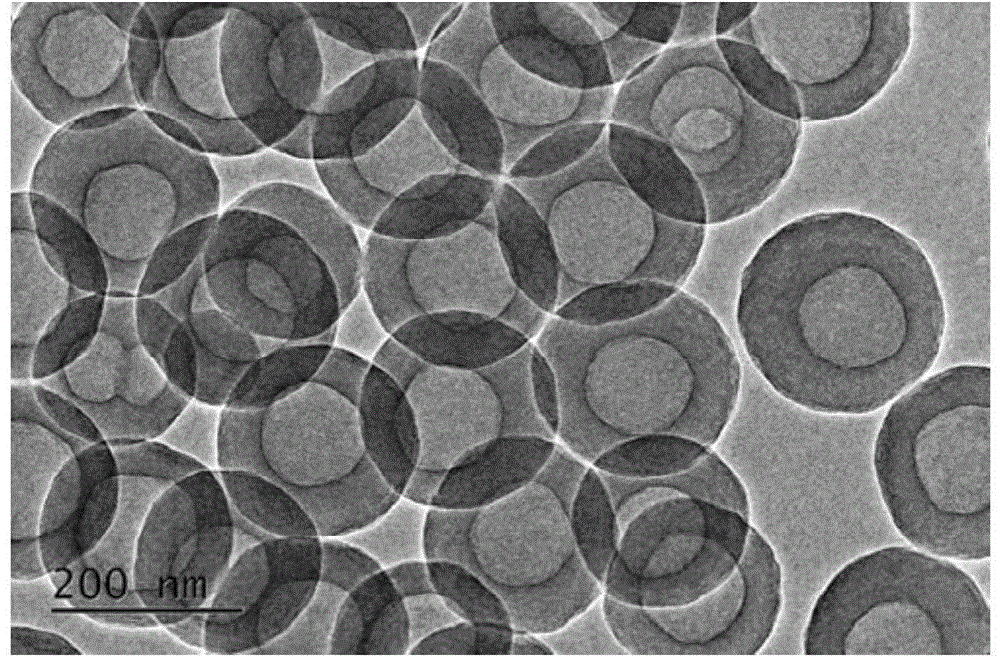

[0101] Finally, a single-layer hollow carbon sphere with a clean interior is obtained. The outer diameter of the obtained carbon sphere is 160-200nm, the inner diameter is 100-120nm, and the wall thickness is 30-50nm.

Embodiment A3

[0102] Embodiment A3, using method A to prepare the yolk-shell hollow structure with solid carbon spheres inside:

[0103] The difference with embodiment A1 is:

[0104] Weigh 0.6g 3-aminophenol (5.52mmol) in 40ml H 2 O, then sequentially added 0.2ml mass percent concentration of 25% ammonia (2.60mmol) and 0.6ml mass concentration of 37% formaldehyde solution (8.04mmol).

[0105] The end result is a hollow yolk-shell structure with solid carbon spheres inside. The outer diameter of the obtained hollow carbon sphere structure is 270-360nm, and the diameter of the inner solid sphere is 180-250nm.

[0106] Figure 5 It is the transmission electron microscope (TEM) figure of the hollow yolk-shell carbon sphere material that the interior prepared by the present embodiment is equipped with solid carbon spheres, as can be seen from the figure that the diameter of the internal solid carbon sphere is about 230nm, and the diameter of the external cavity is about 350nm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com