A cleaning method and device for a valve body cleaning machine

A washing machine and valve body technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as hidden dangers in the operation of railway wagons, unsatisfactory cleaning effects, and blockage of brake air passages , to achieve the effect of good cleaning effect, simple structure and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

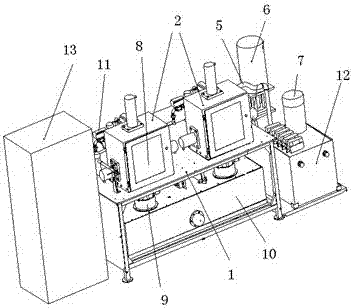

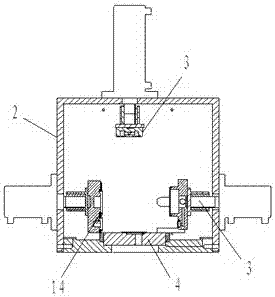

[0016] Embodiments of the present invention: a cleaning method for a valve body cleaning machine. A valve body cleaning chamber is made on the valve body cleaning machine, and a movable clamping module is arranged in the valve body cleaning chamber. The movable clamping module is connected with a hydraulic device, and the valve The body cleaning chamber is connected to the high-pressure water pump and the high-pressure air pump respectively through the inlet pipe, and the valve body cleaning chamber is connected to the discharge pipe. A pneumatic ball valve is made on the inlet pipe and the discharge pipe to control the entry and exit of high-pressure water and compressed air. When cleaning, first Put the valve body to be cleaned into the valve body cleaning chamber, use the movable clamping module to fix the valve body in the center of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com