Preparation method of charcoal-supported palladium-silver nanometer composite catalyst for direct methanol fuel cells

A methanol fuel cell and nanocomposite technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as weakened catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

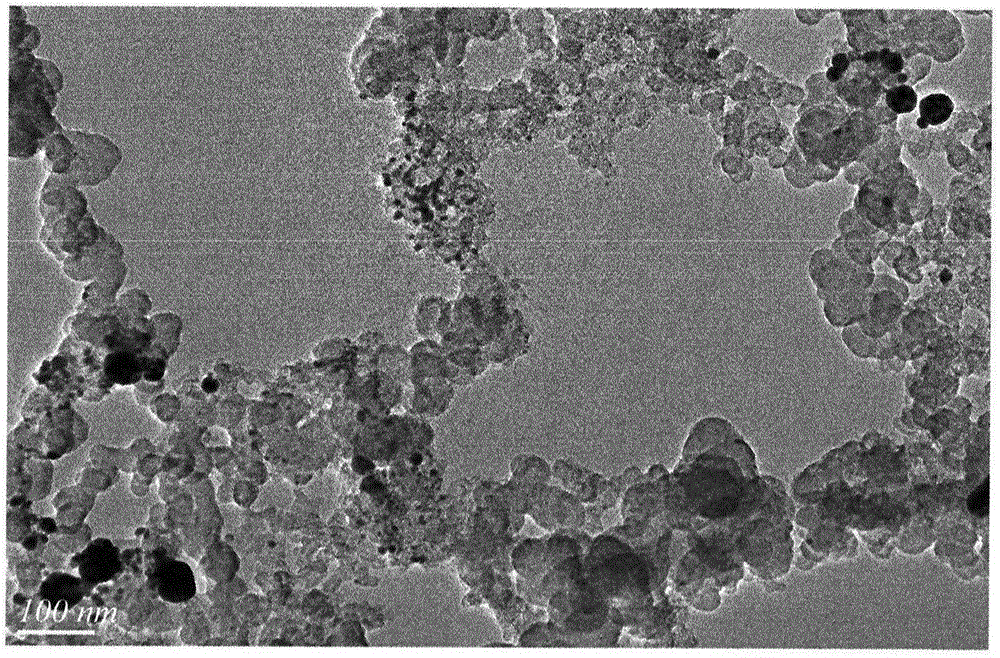

[0019] Embodiment one: in the 4th step of preparation process, NaBH 4 The dosage is 128 mg; other preparation conditions remain unchanged. The TEM picture of the obtained catalyst is as figure 1 shown. figure 1 It was shown that palladium silver nanoparticles were successfully loaded on the surface of activated carbon support. figure 2 is the resulting catalyst in 0.1M KOH+1M CH 3 CV curves in OH mixed solution. The current density of the CV curves was normalized by the mass of the catalyst. from figure 2 It can be seen that the peak electrode potential of the current density of the electrochemical oxidation of methanol on the catalyst surface is -0.15V. At this potential, the current density of the electrochemical oxidation of methanol is 0.71mA·mg -1 catalyst. Additionally, from figure 2 It can be found that no poisoning peak of methanol oxidation intermediates appears during cathodic polarization. The results show that the catalyst has good resistance to methan...

Embodiment approach 2

[0020] Embodiment two: in the 4th step of preparation process, NaBH 4 The dosage is 256 mg; other preparation conditions remain unchanged. The TEM picture of the obtained catalyst is as image 3 shown. image 3 It was shown that palladium silver nanoparticles were successfully loaded on the surface of activated carbon support. Figure 4 is the resulting catalyst in 0.1M KOH+1M CH 3 CV curves in OH mixed solution. The current density of the CV curves was normalized by the mass of the catalyst. from Figure 4 It can be seen that the peak electrode potential of the current density of the electrochemical oxidation of methanol on the catalyst surface is -0.15V. At this potential, the current density of the electrochemical oxidation of methanol is 3.56mA·mg -1 catalyst. Although in the cathodic polarization process, the CV curve of the catalyst showed a current density of 1.64mA·mg at -0.33V -1 Catalyst poisoning peak. But the ratio of current density between the current p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com