Application of metal oxide modified CePO4 catalyst to collaborative denitration and demercuration

A technology of catalysts and oxides, applied in the direction of physical/chemical process catalysts, chemical/physical processes, chemical instruments and methods, etc., can solve the problems of low mercury oxidation activity and poor sulfur resistance, and achieve easy-to-obtain and good-quality raw materials for preparation SCR active, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

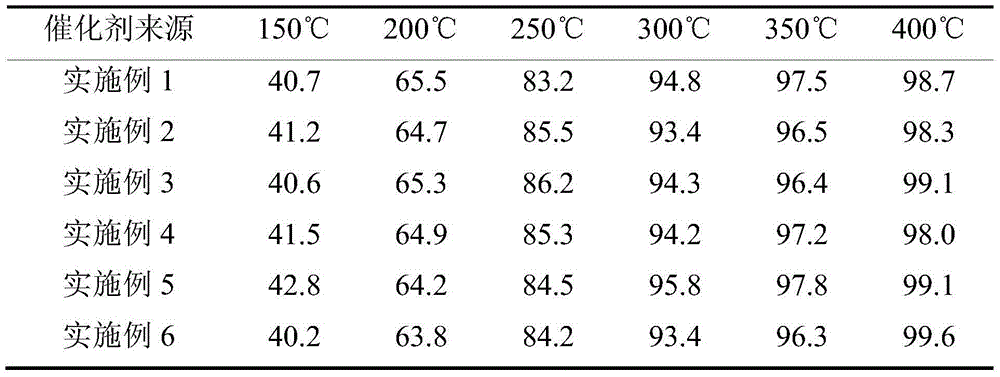

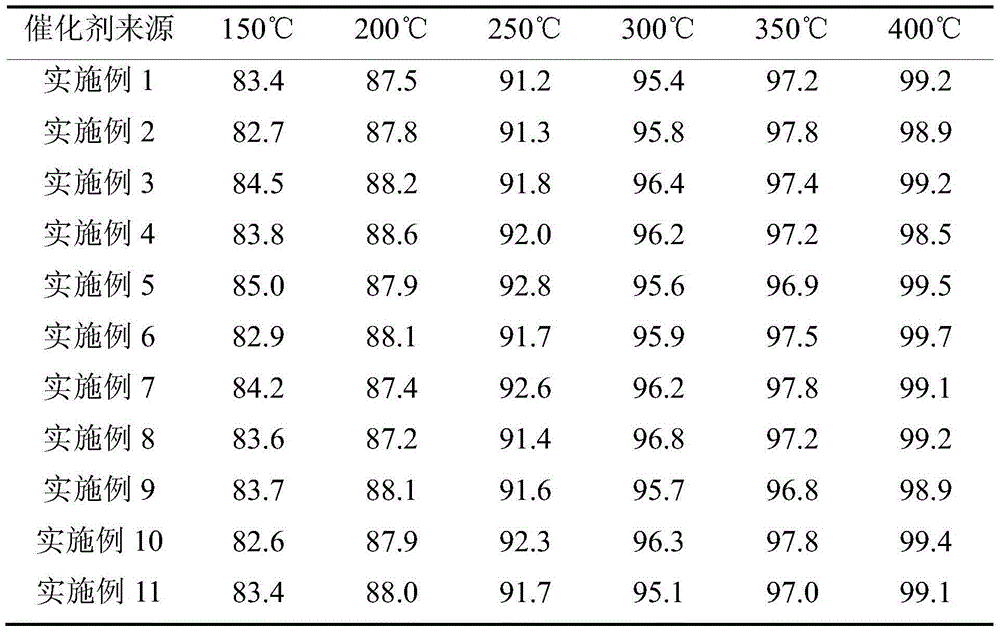

Embodiment 1

[0039] Catalyst preparation:

[0040] (1) Mix cerium nitrate hexahydrate and phosphoric acid at a molar ratio of 1:1, add a certain amount of urea (the molar ratio to cerium nitrate is 2.5), react at 80°C for 2 hours, cool the resulting mixture, let it stand, and wash it A white precipitate of cerium phosphate was obtained.

[0041] (2) Dissolve 0.6 mmol of cobalt nitrate in 200 ml of deionized water, add 0.02 mol of cerium phosphate obtained in step (1), and stir evenly.

[0042] (3) After the mixture obtained in step (2) is dried, it is calcined at 300° C. for 8 hours in an air atmosphere to obtain a catalyst.

Embodiment 2

[0044] Catalyst preparation:

[0045] (1) Mix cerium nitrate hexahydrate and phosphoric acid at a molar ratio of 1:1, add a certain amount of urea (the molar ratio to cerium nitrate is 3), react at 80°C for 2 hours, cool the resulting mixture, let it stand, and wash A white precipitate of cerium phosphate was obtained.

[0046] (2) Dissolve 0.6 mmol of manganese nitrate in 200 ml of deionized water, add 0.02 mol of cerium phosphate obtained in step (1), and stir evenly.

[0047] (3) After the mixture obtained in step (2) is dried, it is calcined at 300° C. for 8 hours in an air atmosphere to obtain a catalyst.

Embodiment 3

[0049] Catalyst preparation:

[0050] (1) Mix cerium nitrate hexahydrate and phosphoric acid in a molar ratio of 1:1, add a certain amount of urea (the molar ratio to cerium nitrate is 2), react at 90°C for 2 hours, cool the resulting mixture, let it stand, and wash A white precipitate of cerium phosphate was obtained.

[0051] (2) Dissolve 0.6 mmol of copper nitrate in 200 ml of deionized water, add 0.02 mol of cerium phosphate obtained in step (1), and stir evenly.

[0052] (3) After the mixture obtained in step (2) is dried, it is calcined at 300° C. for 8 hours in an air atmosphere to obtain a catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com