Probiotic fermented beverage and preparation method thereof

A technology for fermented beverages and probiotics, applied in food preparation, bacteria, lactobacilli and other directions used in food preparation, can solve the problem of watermelon juice lactic acid bacteria fermented beverages that cannot obtain color, flavor and taste, undisclosed solutions to watermelon juice quality problems, Issues such as probiotics or lactic acid bacteria strains are not disclosed to achieve the effect of improving juice extraction rate and food safety, enhancing abiotic and biological stability, and maintaining color and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

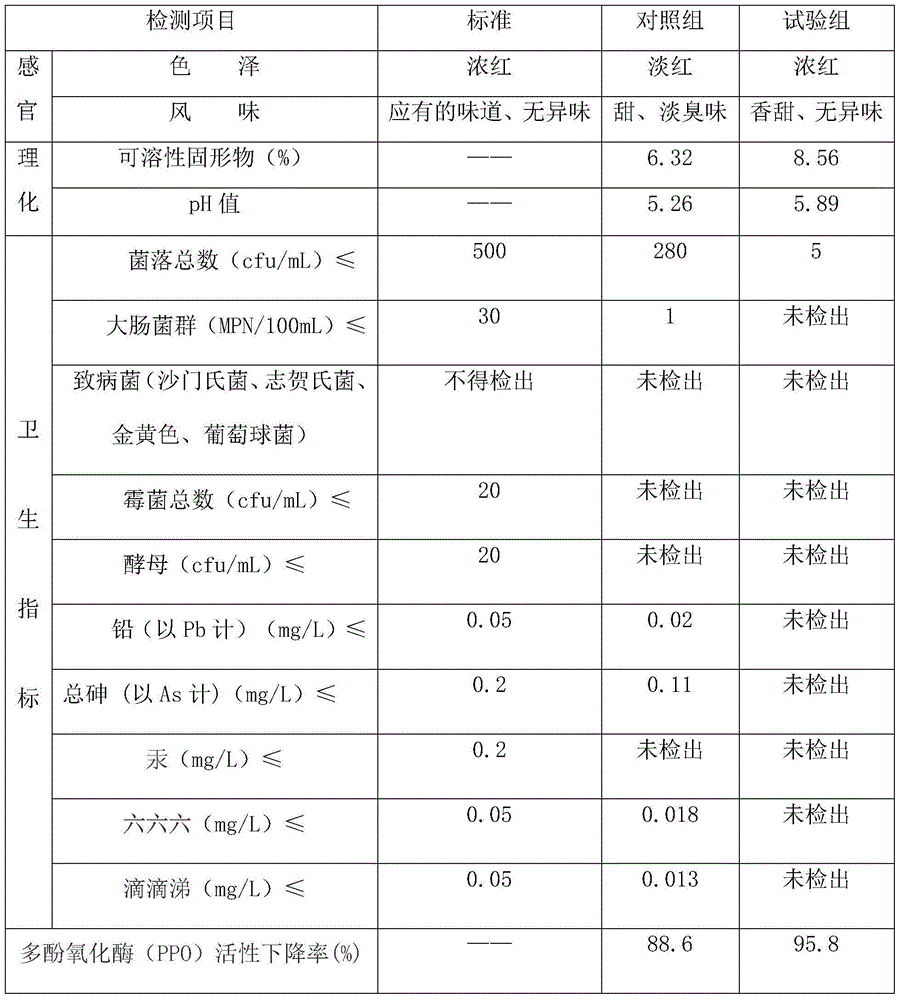

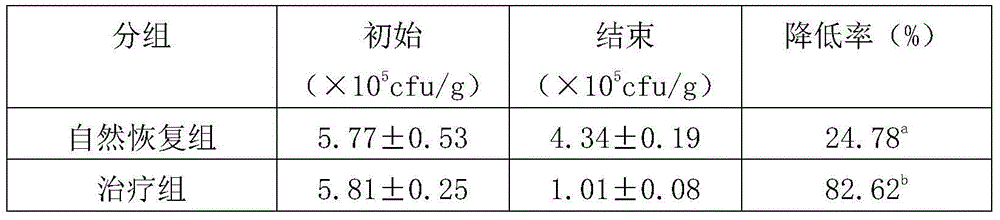

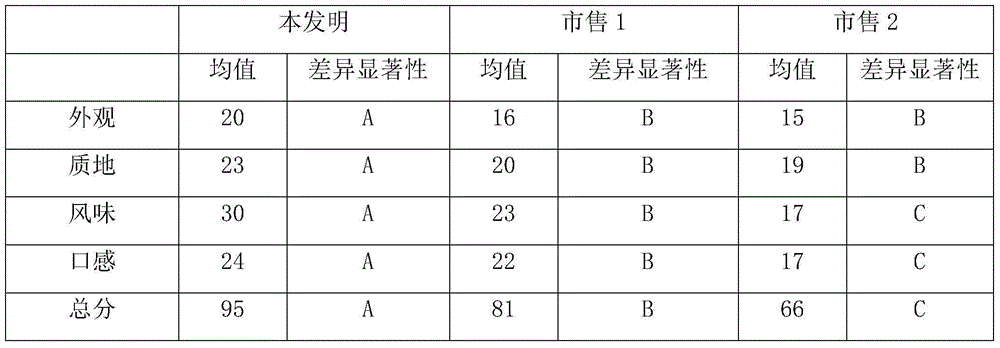

Examples

Embodiment 1

[0046] Embodiment 1 raw material preparation

[0047] Preparation of Modified Dietary Fiber

[0048] The preparation method of the modified dietary fiber comprises the following steps: uniformly mixing inulin, apple fiber, oat fiber, and wheat fiber in a mass ratio of 6:3:3:2, adding water 5 times its mass, and heating at room temperature 300W, Ultrasonic extraction at 40KHz for 12 minutes, and then high-voltage pulsed electric field extraction under the conditions of electric field strength 30kV / cm, pulse time 500μs, and pulse frequency 300Hz; use lactic acid to adjust the pH value to 5.5, add 0.2% mixed enzyme by mass of the mixture, and enzyme at 50°C Decompose for 35 minutes; the enzymatic solution is concentrated under reduced pressure, freeze-dried, and crushed at low temperature until the particle size is 0.2mm to obtain the modified dietary fiber;

[0049] The mixed enzyme is xylanase, cellulase, laccase, pectinase and tannase mixed uniformly in a mass ratio of 4:4:3:...

Embodiment 2

[0052] A preparation method for a probiotic fermented beverage, comprising the steps of:

[0053] 1) Cleaning: After the inspection, the selenium melons are washed, drained, peeled, and pulped;

[0054] 2) Crushing and juicing: Put the melon pulp in a crusher and crush it. The crushing rate is over 98%, and the integrity rate of watermelon seeds is 100%. the first juice

[0055] 3) Colloid mill and degassing: Put the initial juice into the colloid mill, adjust the gap between the stator and the rotor, so that the particle size of the exported watermelon juice reaches 150 μm, and then treat it in a high-voltage pulse electric field at room temperature for 4 minutes, and vacuum degas the watermelon Original juice;

[0056] 4) Enzymolysis: adding cellulase and protease to watermelon raw juice to make the contents 80ppm and 100ppm respectively, enzymatically hydrolyzing at 50°C for 2 hours to obtain watermelon juice enzymatic hydrolysis;

[0057] 5) Enzyme inactivation and dega...

Embodiment 3

[0070] A preparation method for a probiotic fermented beverage, comprising the steps of:

[0071] 1) Cleaning: Wash, drain, peel, and remove the flesh of the watermelon with strong red flesh after inspection;

[0072] 2) Crushing and juicing: Put the melon pulp in a crusher and crush it. The crushing rate is over 98%, and the integrity rate of watermelon seeds is 100%. the first juice

[0073] 3) Colloid mill, degassing: Put the initial juice into the colloid mill, adjust the gap between the stator and the rotor, so that the particle size of the exported watermelon juice reaches 100 μm, and then treat it in a high-voltage pulse electric field at room temperature for 3 minutes, and vacuum degas the watermelon Original juice;

[0074] 4) Enzymolysis: Add cellulase and protease to watermelon raw juice to make the contents 70ppm and 90ppm respectively, and enzymolyze at 45°C for 1.5h to obtain watermelon juice enzymatic hydrolysis;

[0075] 5) Enzyme inactivation and degassing:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com