Three-dimensional graphene-hollow carbon sphere nanocomposite and preparation method thereof

A technology of nanocomposites and hollow carbon spheres, which can be used in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., and can solve the problems of hollow carbon spheres, such as lower electronic conductivity than graphene, low Coulombic efficiency and reversible capacity, and poor conductivity , to achieve the effects of flexible and controllable mechanical flexibility, inhibition of dissolution and shuttling, and good electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

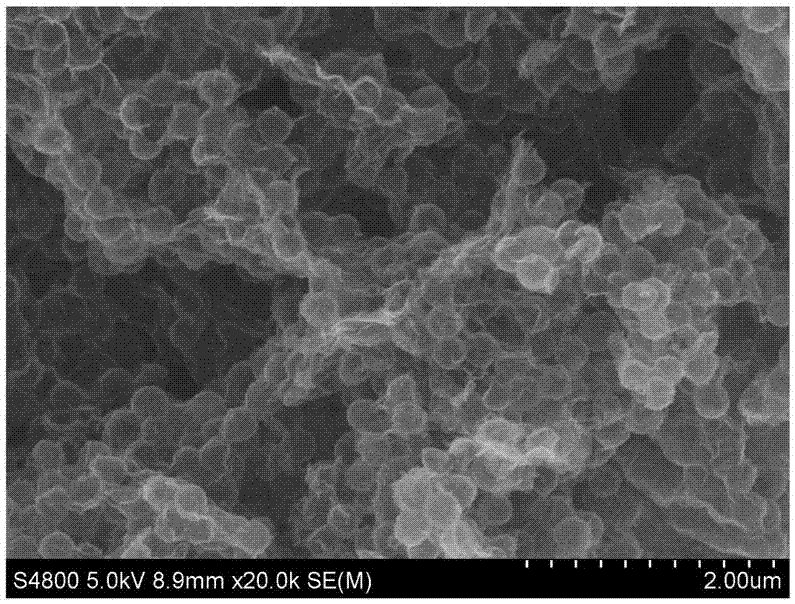

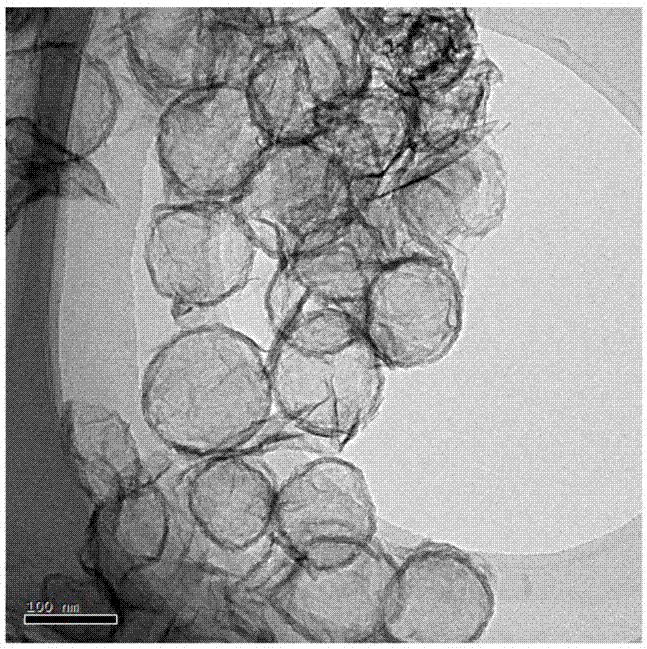

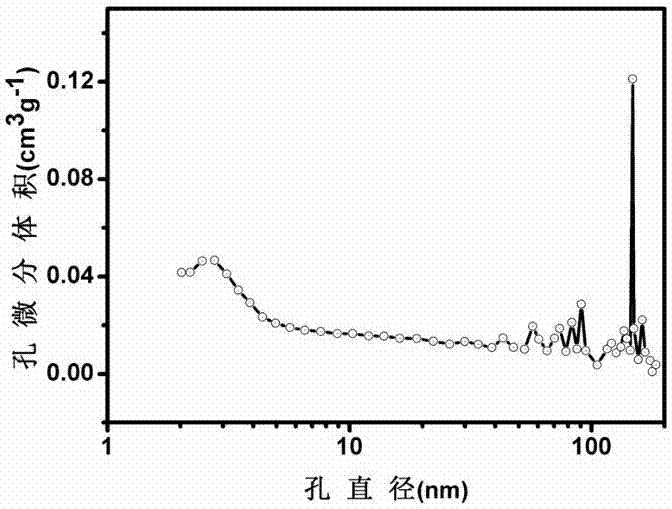

[0037] A three-dimensional graphene-hollow carbon sphere nanocomposite of the present invention, the nanocomposite is composed of hollow carbon spheres and graphene, and the hollow carbon spheres are uniformly distributed in a three-dimensional network structure formed by graphene.

[0038] In this embodiment, the mass ratio of the hollow carbon spheres to the graphene is 7:3, the particle size of the hollow carbon spheres is in the range of 140nm-160nm, and the average particle size is 150nm.

[0039] A method for preparing the three-dimensional graphene-hollow carbon sphere nanocomposite of the above-mentioned present embodiment, comprising the following steps:

[0040] (1) Add 15ml tetraethyl orthosilicate to a mixed solvent composed of 10ml ammonia water, 200ml ethanol and 100ml water under magnetic stirring, stir at 30°C for 10min, then add 10ml ethanol solution of resorcinol in turn ( Containing 1.44g resorcinol), 2.12g formaldehyde aqueous solution (mass fraction of for...

Embodiment 2

[0058] A three-dimensional graphene-hollow carbon sphere nanocomposite of the present invention, the nanocomposite is composed of hollow carbon spheres and graphene, and the hollow carbon spheres are uniformly distributed in a three-dimensional network structure formed by graphene.

[0059] In this embodiment, the mass ratio of the hollow carbon spheres to the graphene is 8:1, the particle size of the hollow carbon spheres is in the range of 140nm-160nm, and the average particle size is 150nm.

[0060] A method for preparing the three-dimensional graphene-hollow carbon sphere nanocomposite of the above-mentioned present embodiment, comprising the following steps:

[0061] (1) Add 15ml tetraethyl orthosilicate to a mixed solvent composed of 10ml ammonia water, 200ml ethanol and 100ml water under magnetic stirring, stir at 30°C for 10min, then add 10ml ethanol solution of resorcinol in turn ( Containing 1.44g resorcinol), 2.12g formaldehyde aqueous solution (the mass fraction of...

Embodiment 3

[0066] A three-dimensional graphene-hollow carbon sphere nanocomposite of the present invention, the nanocomposite is composed of hollow carbon spheres and graphene, and the hollow carbon spheres are uniformly distributed in a three-dimensional network structure formed by graphene.

[0067] In this embodiment, the mass ratio of the hollow carbon spheres to the graphene is 8:2, the particle size of the hollow carbon spheres is in the range of 180nm-220nm, and the average particle size is 200nm.

[0068] A method for preparing the three-dimensional graphene-hollow carbon sphere nanocomposite of the above-mentioned present embodiment, comprising the following steps:

[0069] (1) Add 15ml tetraethyl orthosilicate to a mixed solvent consisting of 30ml ammonia water, 150ml ethanol and 50ml water under magnetic stirring, stir at 30°C for 10min, then add 10ml ethanol solution of resorcinol in turn ( Containing 1.44g resorcinol), 2.12g formaldehyde aqueous solution (the mass fraction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com