Quick and overregulation-free cooling crystallization reaction kettle temperature control method

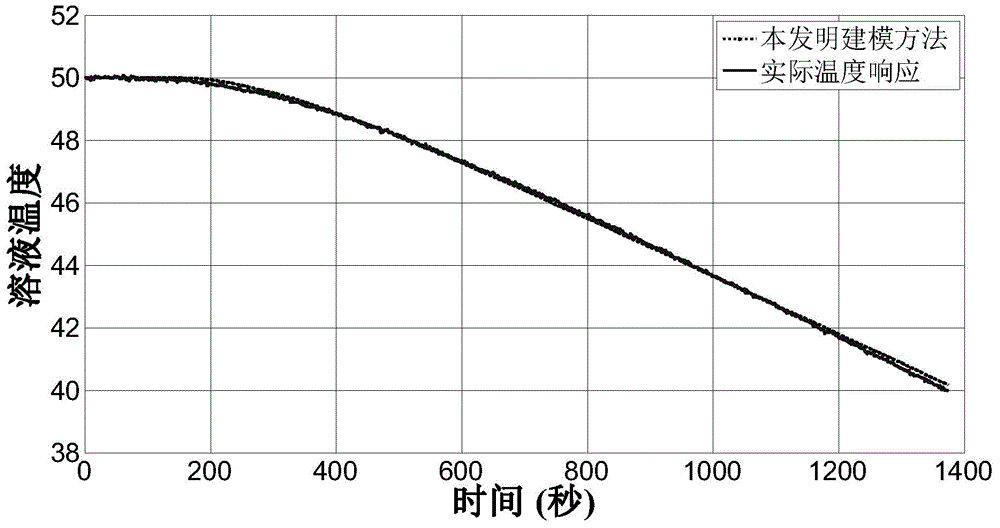

A temperature control method and crystallization reactor technology, which are applied in the direction of temperature control using electric methods, to achieve optimal control performance, fast and non-overshoot cooling control effect, and overcome time-varying uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] The embodiment adopts 10 liters of crystallization reaction kettles, and 4 liters of glutamic acid aqueous solutions with a concentration of 10% are installed inside, and a refrigeration / heating circulator is configured, which is composed of a Freon cooling compressor with a cooling power of 2kw and an electronic heating tube with a heating power of 2kw . The refrigerating power of the freon cooling compressor is turned on and the operating range is 40-100%, and the heating power of the electronic heating tube is turned on and the operating range is 0-100%.

[0020] The specific implementation steps of the present invention are as follows:

[0021] Step 1: Open-loop cooling identification

[0022] First, turn on the electronic heating tube to raise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com