Slip sheet of refrigeration compressor and manufacturing method thereof

A technology for refrigeration compressors and manufacturing methods, applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of low yield, difficult processing, high carbon content, etc., and achieve high yield rate, wide range of material selection, Good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Steel slabs consisting of the following chemical composition (mass)%

[0043] C 0.32-0.40 Si 0.17-0.37 Mn 0.40-0.70 Cr 1.00-1.30 Mo 0.20-0.30Al 0.70-1.10 V 0.1-0.2 Fe balance

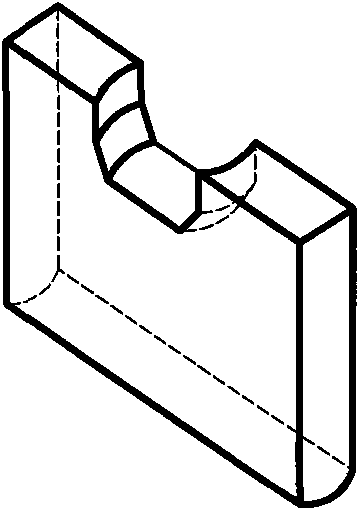

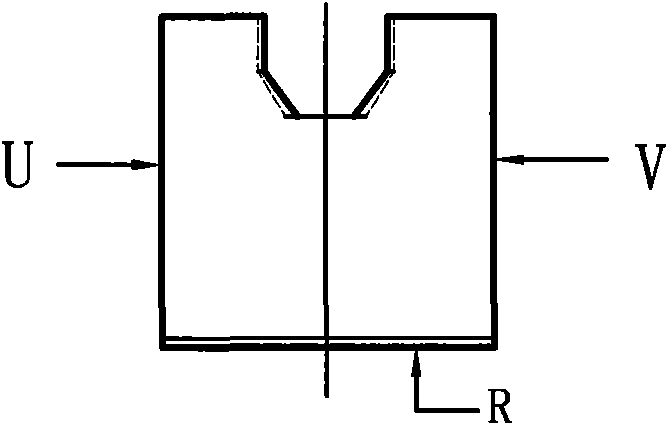

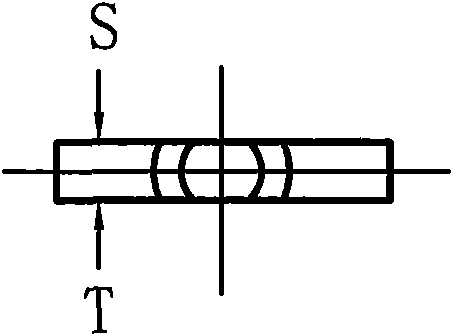

[0044] First, it is hot-rolled into a flat strip, and then cold-drawn according to the width, thickness, and R arc size of the slide, and then cut out the shape required by the slide with a band saw, and then milling out the grooves on the slide with a milling cutter. After the groove is quenched and tempered at 1050°C by conventional vacuum heat treatment, the large flat end face is ground first with a grinding machine, then the R surface is shaped and ground, and then the end face is vertically ground until it meets the surface requirements, such as figure 1 , figure 2 , image 3 In the form shown, gas nitriding is performed. The gas nitriding process is as follows: the furnace temperature is 500-550°C, nitrogen and ammonia are charged in stages, the ammonia decomposition rate is 10-60%, an...

Embodiment 2

[0049] Steel slabs consisting of the following chemical composition (mass)%

[0050] C 0.35-0.42 Si 0.20-0.45 Mn 0.30-0.60 Cr 1.35-1.65 Mo 0.15-0.25Al 0.70-1.10 Fe balance

[0051] Except nitriding treatment, all the other are with embodiment 1.

[0052] The nitriding treatment is a salt bath nitriding treatment: the slide is placed in a molten salt synthesized from various carbonates and urea, and the temperature is kept at 500-600°C for about 1-4 hours; then Cool with an oxidizing liquid salt bath. After nitriding, the slides were surface ground, and the measurement results of the obtained slides are shown in Table 1.

Embodiment 3

[0054] Steel slabs consisting of the following chemical composition (mass)%

[0055]C 0.37-0.44 Si 0.17-0.37 Mn 0.90-1.20 Cr 0.90-1.20 Mo 0.20-0.30Al 0.60-1.00 Fe balance.

[0056] The rest of the conditions are the same as those in step 1, and the obtained slides have the measurement results shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com