On-line visual inspection method for surface quality of plate with variable thickness

A technology of surface quality and visual inspection, which is applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects, etc., can solve the problem of not considering the adjustment of the imaging scheme of the hot slab, and achieve the effect of ensuring physical resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

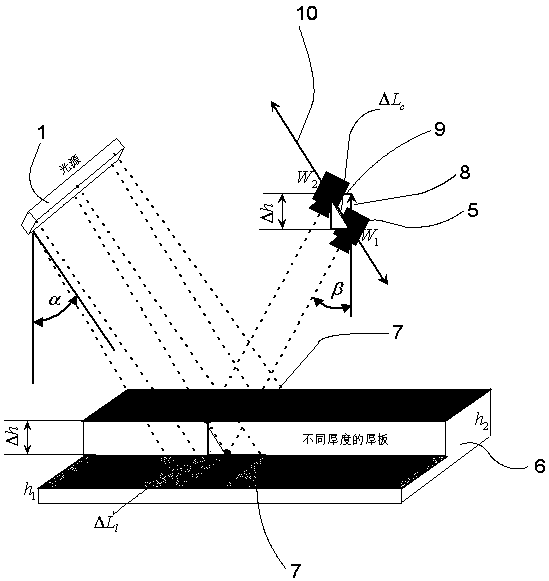

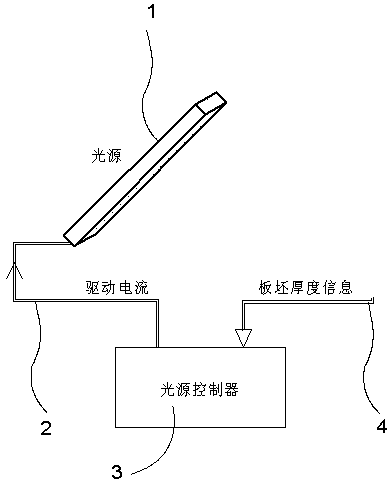

[0021] see figure 1 and figure 2 , an online visual inspection method for the surface quality of plates with variable thickness. For the imaging of the surface of high-temperature slabs with different thicknesses, the imaging distance is kept consistent by automatically adjusting the position of the camera, and when the position of the light source is fixed, the current of the light source is maintained. The illuminance at the imaging position of the slab is consistent, so that when imaging slabs of different thicknesses, an image with consistent grayscale is output; the steps are:

[0022] First, the light source 1 and the camera 5 are located above the slab 6, and the position of the light source 1 is fixed; the projection angle of the light source is , the imaging angle of the camera is , the projection distance of the light source is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com