Prefabricated shear wall horizontal abutted seam buckle welding built-up connection device

A technology of horizontal jointing and combined connection, applied in the direction of walls, building components, buildings, etc., can solve the problems of high welding cost, high difficulty, hindering the installation of horizontally distributed steel bars, etc. The effect of assembling time-saving and labor-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to further understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the scope expressed in the embodiments.

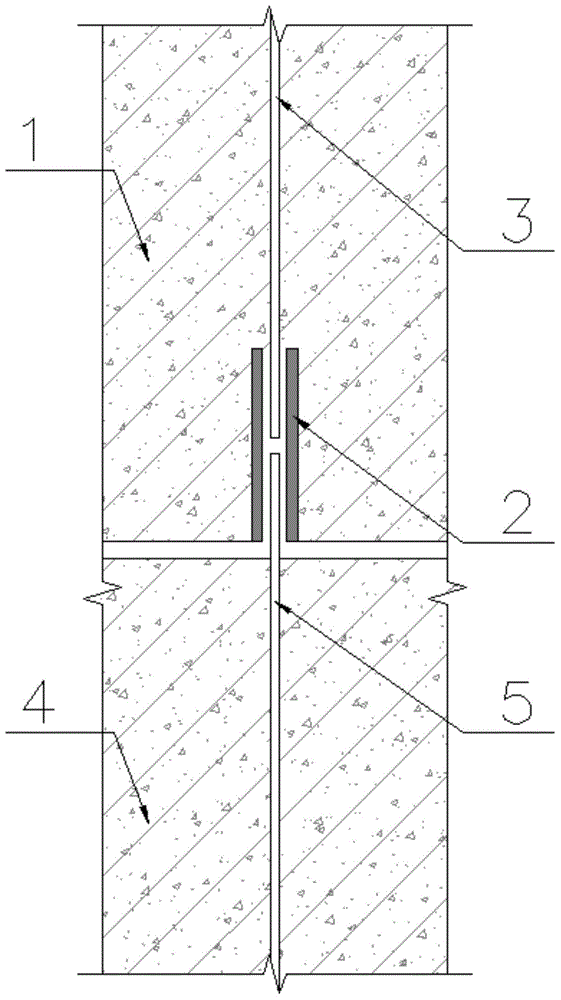

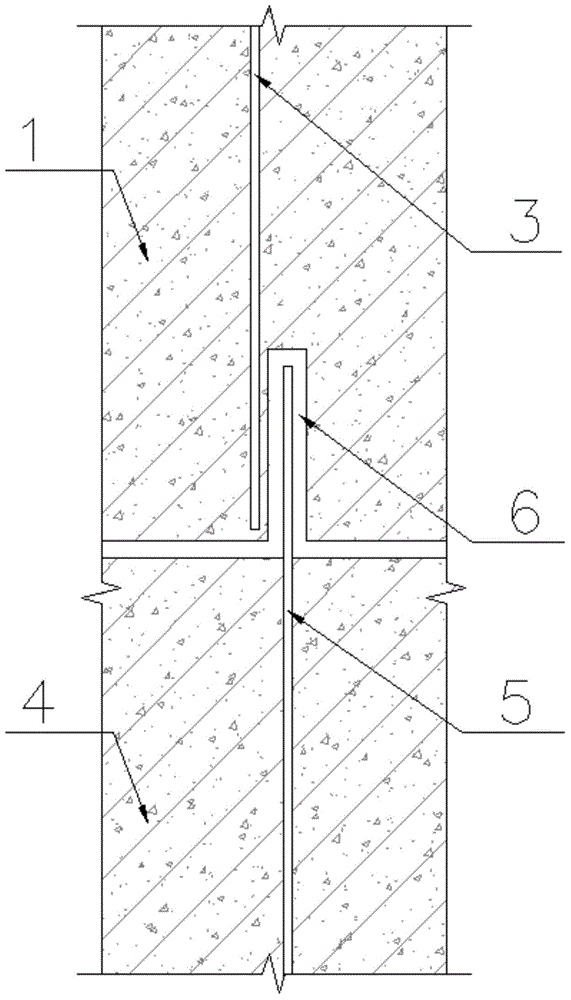

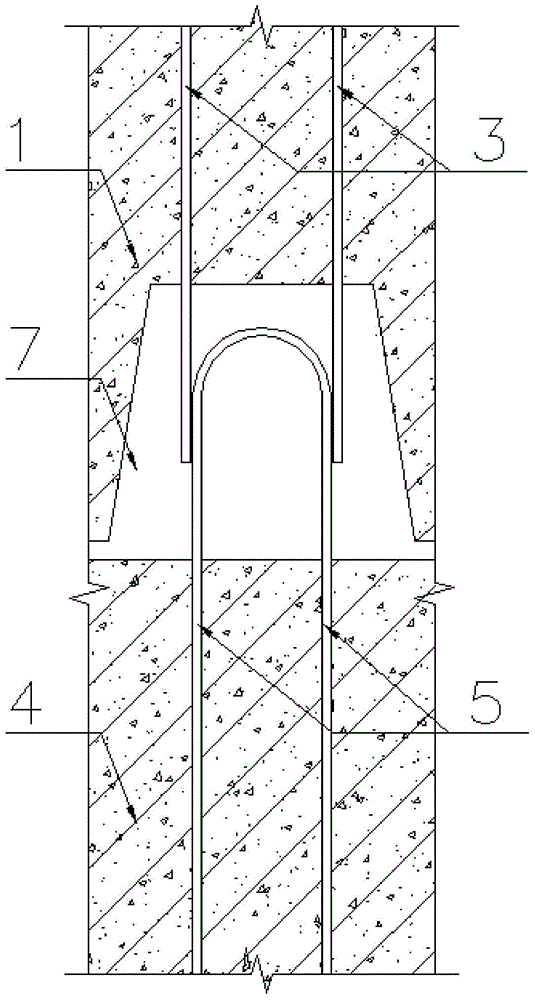

[0062] Such as Figure 5 As shown, an assembled shear wall horizontal seam buckle welding combined connection device is used for the connection of the horizontal seam when assembling the upper prefabricated shear wall 1 and the lower prefabricated shear wall 4. It mainly consists of the upper anchor plate 9, The last connection reinforcement 3, the upper horizontal reinforcement 15, the vertical connection bolt 10, the lower anchor plate 11, the lower connection reinforcement 5, the lower horizontal reinforcement 16, the connection groove box 12, the compression spring 13, the connection block 14 and the hinge 17 form.

[0063] The upper anchor plate 9 is set close to the bottom surface of the upper prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com