Preparing method of hyperdispersant and non-dyed polyurethane elastic fiber

A technology of polyurethane elasticity and hyperdispersant, which is applied in the field of spandex spinning technology, can solve the problems of changing the applicability of spandex yarn, the influence of molecular structure, and long switching cycle, etc., and achieve the effect of long storage time, low production cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

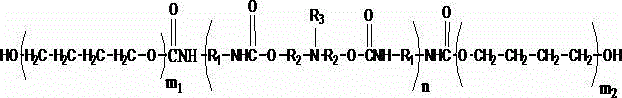

[0037] Embodiment 1, a kind of hyperdispersant, the molecular formula of described hyperdispersant is

[0038]

[0039] In the formula: R1 is the residue of diisocyanate, R2 is the residue of glycol amine, R3 is methyl or tert-butyl, wherein, n=2, the solvation segment HO(-CH 2 -CH 2 -CH 2 -CH 2 -O-) m1 H, HO(-CH 2 -CH 2 -CH 2 -CH 2 -O-) m2 The molecular weight of H is 1500, wherein, n, m1, m2 are all positive integers;

[0040] This hyperdispersant has a BAB-type block structure, in which segment A is an anchoring group, and its main function is to adsorb on the surface of pigment or carbon black to prevent desorption of polyurethane hyperdispersant; segment B is a solvation chain, which The main function is to make a protective layer with a certain thickness on the surface of the pigment or carbon black to achieve steric hindrance and prevent the particles from approaching each other to form tight aggregates and flocs. At the same time, due to the good compatibil...

Embodiment 2

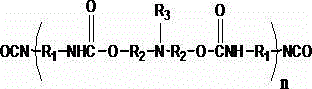

[0041] Embodiment 2, a kind of hyperdispersant, the molecular formula of described hyperdispersant is

[0042]

[0043] In the formula: R1 is the residue of diisocyanate, R2 is the residue of glycol amine, R3 is methyl or tert-butyl, wherein, n=8, the above-mentioned synthetic solvation segment HO(-CH 2 -CH 2 -CH 2 -CH 2 -O-) m1 H, HO(-CH 2 -CH 2 -CH 2 -CH 2 -O-) m2 The molecular weights of H are all 3500, where n, m1 and m2 are all positive integers.

Embodiment 3

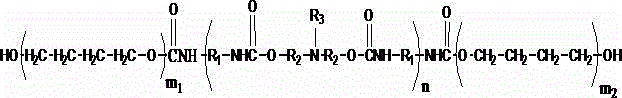

[0044] Embodiment 3, a kind of hyperdispersant, the molecular formula of described hyperdispersant is

[0045]

[0046] In the formula: R1 is the residue of diisocyanate, R2 is the residue of glycol amine, R3 is methyl or tert-butyl, wherein, n=4, the above-mentioned synthetic solvation segment HO(-CH 2 -CH 2 -CH 2 -CH 2 -O-) m1 H, HO(-CH 2 -CH 2 -CH 2 -CH 2 -O-) m2 The molecular weights of H are respectively 2000, wherein n, m1 and m2 are all positive integers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com