Separating and screening method for saline-alkaline-resistant bacteria degrading petroleum hydrocarbon

A technology for separation and screening of petroleum hydrocarbon degrading bacteria, which is applied in the field of environmental remediation, can solve the problems of petroleum hydrocarbon degrading bacteria not adapting to the saline-alkali soil environment, affecting the degradation effect of growth active agents, etc., so as to improve the quality of the micro-ecological environment and improve the The effect of micro-ecological environment quality and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] (1) Strain screening

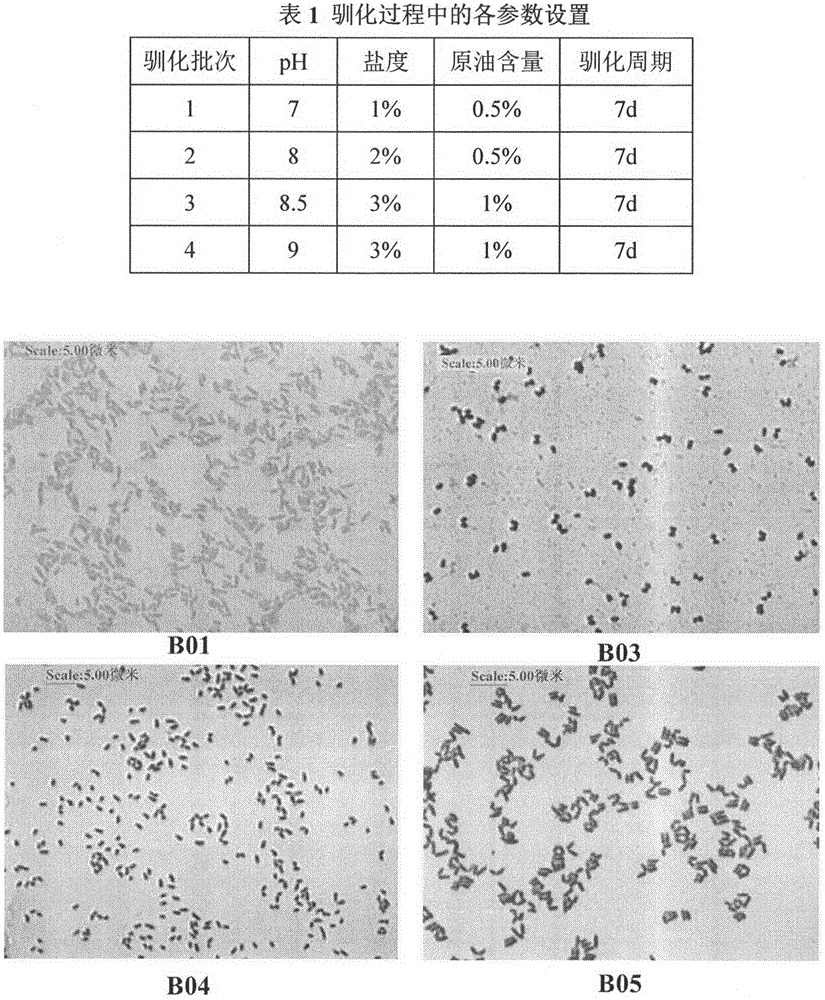

[0021] Weigh 10g of petroleum-contaminated soil and oil sludge (both collected from Dagang Oilfield), inoculate them into a sterilized 250ml Erlenmeyer flask filled with 90ml of inorganic salt medium by aseptic operation, shake at 30°C and 160rpm Cultivate for 7 days, then inoculate 10 mL of the enrichment solution into fresh crude oil inorganic salt medium, and culture continuously for 4 to 5 times under the same conditions. During the acclimatization process, the pH, salinity and crude oil content of the medium gradually increase. as table 1 shown.

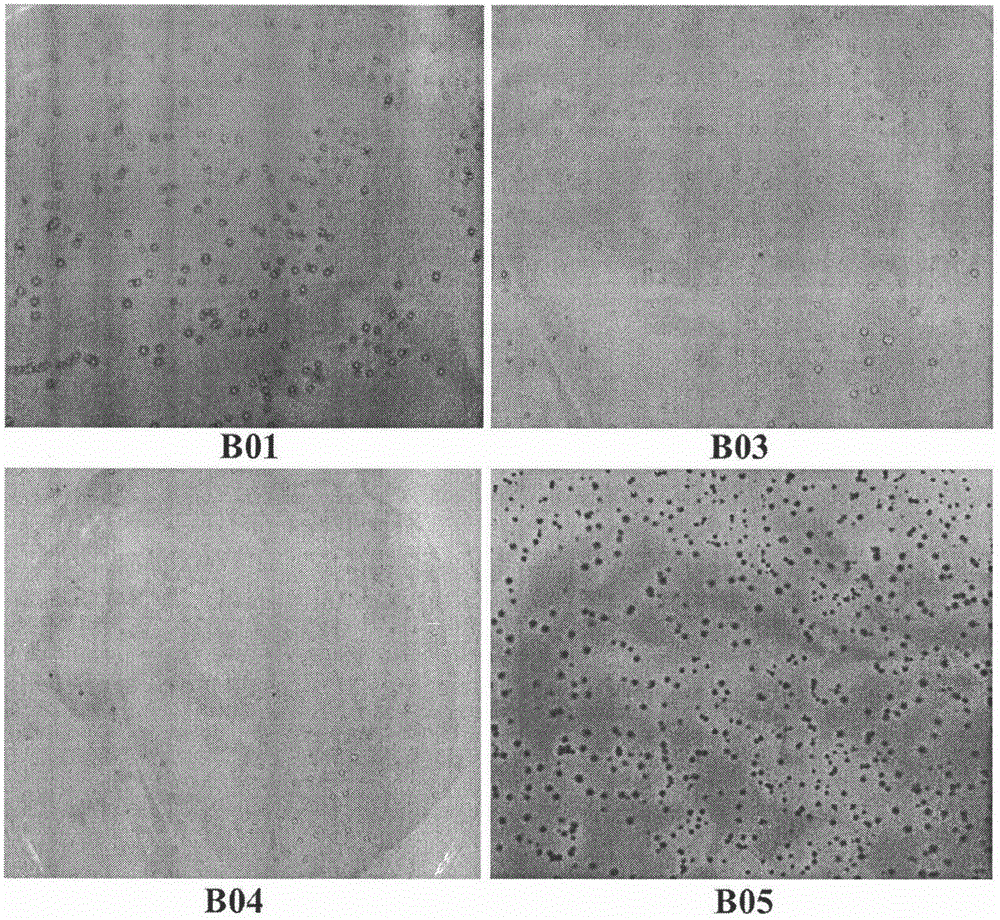

[0022] After the acclimatization was completed, the culture solution was diluted in gradient and spread on LB-agar plates. After the colonies grew out, single colonies of different shapes were picked and purified by streaking to isolate single bacteria. Observe the shape of bacteria under a microscope, Such as figure 1 shown.

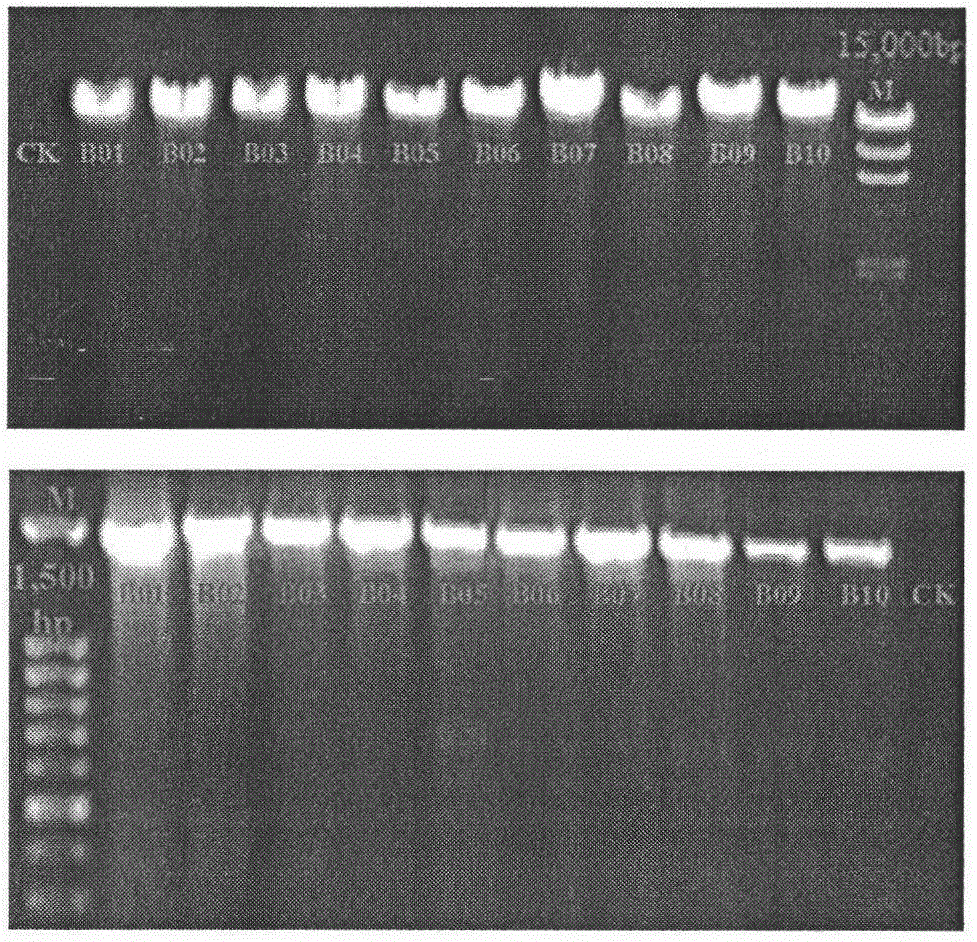

[0023] Then pick the single bacteria after separation and purifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com