Process for directly decomposing and separating natural gas hydrate mined by solid fluidization on seabed

A solid-state fluidized mining and hydrate technology, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problem of difficult separation of hydrate and sediment particles, so as to save production space, reduce operating costs, and reduce lift The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

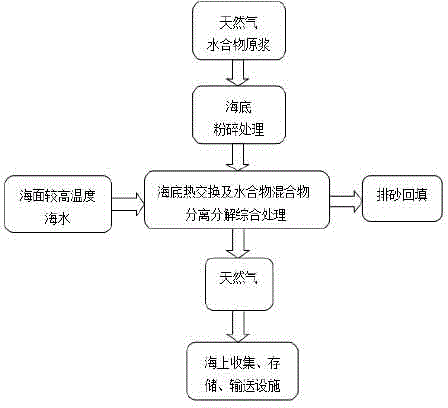

[0010] Further illustrate the present invention below in conjunction with accompanying drawing:

[0011] Such as figure 1 As shown, the present invention directly decomposes and separates the natural gas hydrate seabed of solid-state fluidization exploitation, comprising the following steps:

[0012] ① The natural gas hydrate raw slurry extracted by the subsea excavator and pumped is transported to the subsea crushing device for crushing treatment. The purpose is to make the subsequent decomposition of hydrate particles more efficient in the integrated device for seabed heat exchange and hydrate mixture separation and decomposition.

[0013] ②The crushed hydrate mixture is transported to the submarine heat exchange and hydrate mixture separation and decomposition comprehensive device, and the huge energy stored in the large temperature difference between the sea surface seawater and the seabed seawater is used as a heat source to directly process the natural gas hydrate in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com