A kind of hydraulic forming device for pressing briquette and its control method

A control method and hydraulic forming technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problem that the water content, particle size and binder ratio of pulverized coal are not high, and the forming device cannot achieve direct The problems of demoulding and insufficient compactness of pulverized coal can achieve a wide range of applications, good waterproof and wear-resistant effects, and the effect of reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The pressing of embodiment 1 briquette

[0045] Choose anthracite as raw material and cationic emulsified asphalt as binder. The anthracite is pressed into coal by using a hydroforming device, and the control method specifically includes the following steps:

[0046] Step A: Grinding the anthracite through a ball mill, the ball milling time is 8 hours, and the particle size of the obtained coal powder is less than 1mm.

[0047] Step B: Add binder and water to the coal powder, mix uniformly to form a mixture, and make the mass of cationic emulsified bitumen be 3% of the mass of coal powder, and the mass of water be 20% of the mass of coal powder.

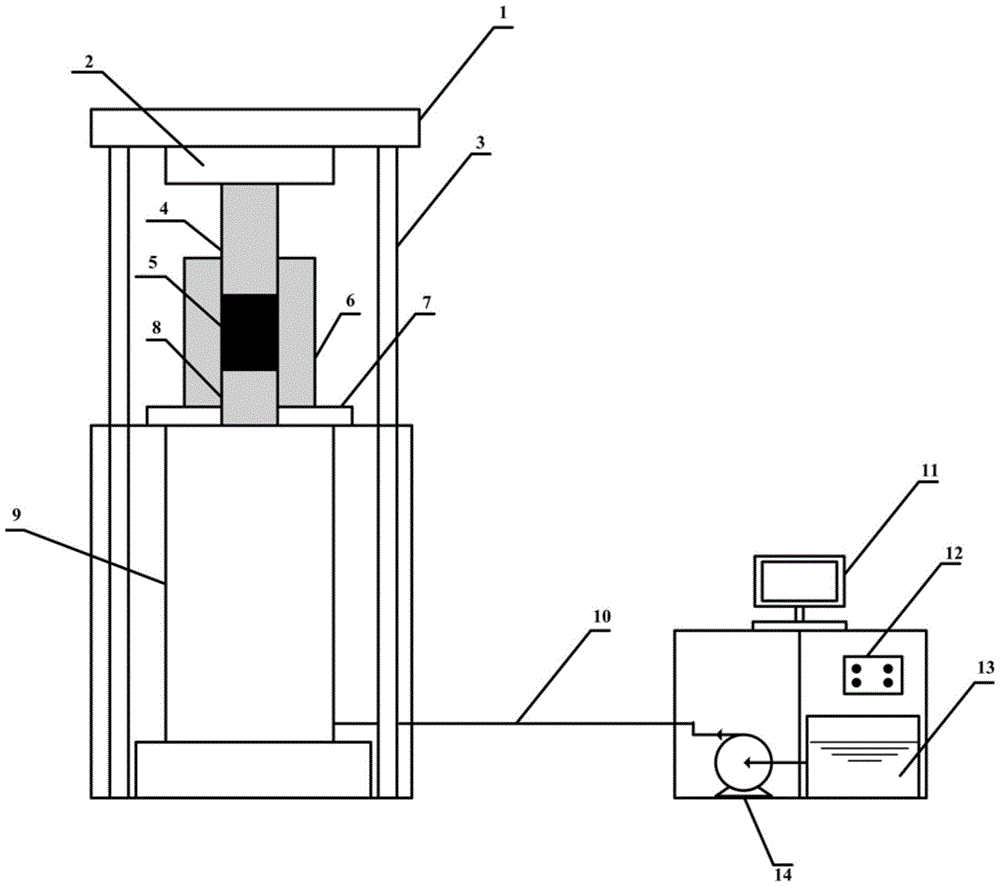

[0048] Step C: Fix the cylindrical lower plunger 8 on the slot of the working platform, fix the cylindrical upper plunger 4 on the top mold fixing plate 2, place the cylindrical mold 6 on the stripping plate 7, and put the mixture Put it into the mold and complete the filling.

[0049] Step D: Turn on the switch on the cont...

Embodiment 2

[0052] The pressing of embodiment 2 briquettes

[0053] Choose anthracite as raw material and cationic emulsified asphalt as binder. The anthracite is pressed into coal by using a hydroforming device, and the control method specifically includes the following steps:

[0054] Step A: Grinding the anthracite through a ball mill, the ball milling time is 8 hours, and the particle size of the obtained coal powder is less than 1mm.

[0055] Step B: Add binder and water to the coal powder, mix uniformly to form a mixture, and make the mass of cationic emulsified bitumen be 10% of the mass of coal powder, and the mass of water be 10% of the mass of coal powder.

[0056] Step C: Fix the cylindrical lower plunger 8 on the slot of the working platform, fix the cylindrical upper plunger 4 on the top mold fixing plate 2, place the cylindrical mold 6 on the stripping plate 7, and put the mixture Put it into the mold and complete the filling.

[0057] Step D: Turn on the switch on the co...

Embodiment 3

[0060] The pressing of embodiment 3 briquettes

[0061] Anthracite is selected for pressing, and cationic emulsified asphalt is selected as the binder. The anthracite is pressed into coal by using a hydroforming device, and the control method specifically includes the following steps:

[0062] Step A: Grinding the anthracite through a ball mill, the ball milling time is 8 hours, and the particle size of the obtained coal powder is less than 1mm.

[0063] Step B: Add binder and water to the coal powder, mix uniformly to form a mixture, and make the mass of cationic emulsified bitumen 25% of the mass of coal powder, and the mass of water 5% of the mass of coal powder.

[0064] Step C: Fix the cylindrical lower plunger 8 on the slot of the working platform, fix the cylindrical upper plunger 4 on the top mold fixing plate 2, place the cylindrical mold 6 on the stripping plate 7, and put the mixture Put it into the mold and complete the filling.

[0065] Step D: Turn on the swit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com