Method for preparing polytetrafluoroethylene ordered template based on temperature-controllable, pressure-controllable and friction film forming device

A technology of polytetrafluoroethylene and film-forming devices, which can be applied to flat products, other household appliances, household appliances, etc., and can solve problems such as epitaxial growth of difficult polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

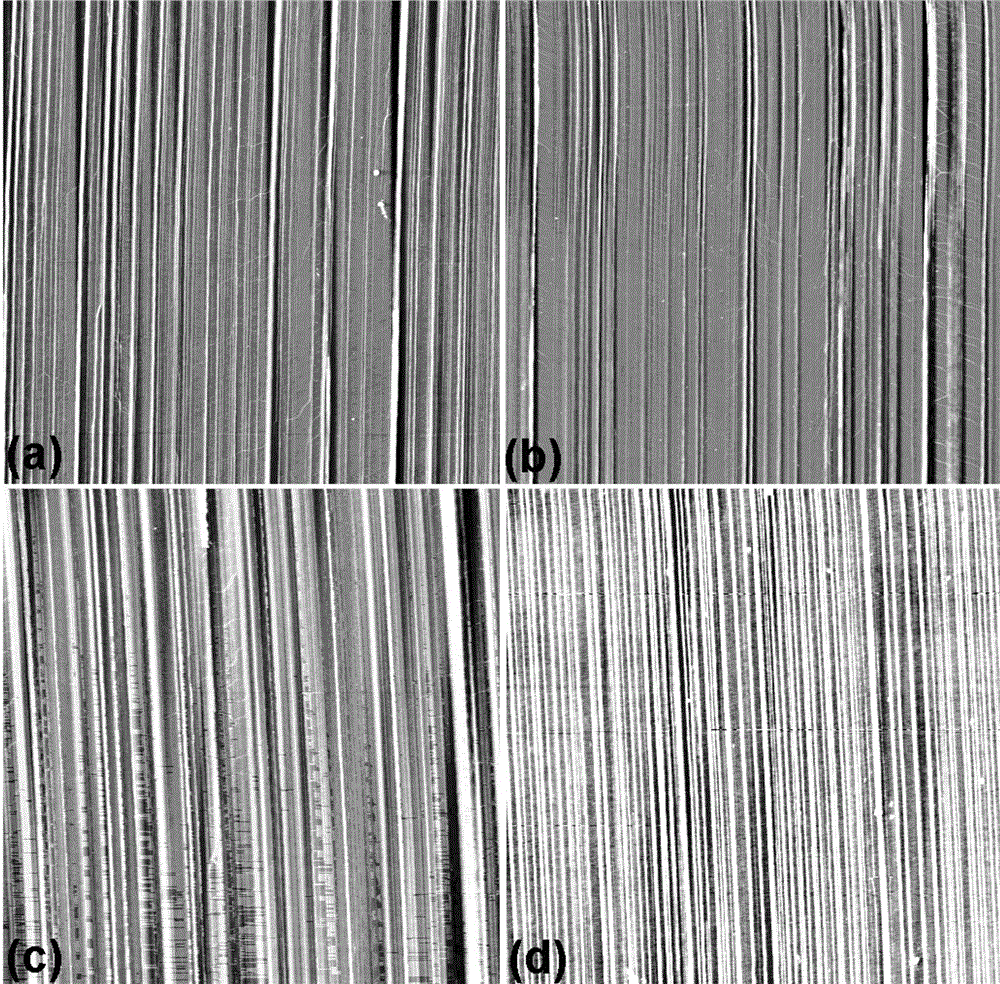

[0022] This example illustrates that by adjusting temperature, pressure, and speed, polytetrafluoroethylene ordered templates with different surface morphologies can be obtained. Proceed as follows:

[0023] 1) Select rod-shaped PTFE with a diameter of 1 cm and 8 glass slides with a length of 7.6 cm and a width of 2.4 cm, and then ultrasonically clean them with acetone, alcohol, and deionized water, and dry them for later use;

[0024] 2) Set the temperature at 120°C (or 125°C), the pressure at 20kg (or 10kg), and the speed at 0.8mm / s (or 0.6mm / s);

[0025] 3) According to the specific preparation steps (2)-(5) of the PTFE ordered template in the above-mentioned content of the invention;

[0026] 4) Observe the surface morphology of the prepared PTFE template with an atomic force microscope, and observe the influence of temperature, speed, and pressure on the template morphology.

[0027] Typical analysis results are attached figure 2 shown. The image scanning area is 20 μ...

Embodiment 2

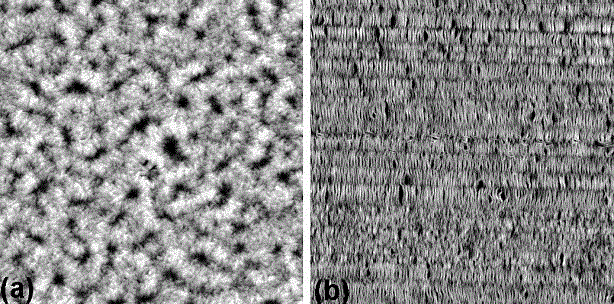

[0029] This example illustrates a method for epitaxially growing a P(VDF-TrFE) ferroelectric polymer film based on a PTFE template. Proceed as follows:

[0030] 1) According to the specific preparation steps (1)-(5) of the PTFE ordered template, prepare the PTFE ordered template, wherein: control the temperature of the hot plate at 120°C, apply a pressure of 15kg, and rub the speed of 0.8mm / s;

[0031] 2) Configure a P(VDF-TrFE) butanone solution with a mass concentration of 1% for the preparation of P(VDF-TrFE) thin films;

[0032] 3) Spin-coat the P(VDF-TrFE) solution on the prepared PTFE template with a spin-coating speed of 1000 rpm; the P(VDF-TrFE) film can be formed after the solvent evaporates;

[0033] 4) Spin-coat a layer of P(VDF-TrFE) film on the surface of a clean glass slide as a reference sample, and compare it with the structure of the film formed on the PTFE ordered template;

[0034] 5) Both types of films were annealed at 135°C for 5 hours to increase their...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com